Air-air heat exchanger with refrigerating function

An air heat exchanger and cooling air technology, which is applied in the direction of machines that use refrigerant evaporation, refrigerators, heat exchangers, etc., can solve the problems of no refrigeration function, etc., achieve large latent heat of vaporization, reduce resistance, and heat transfer The effect of synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

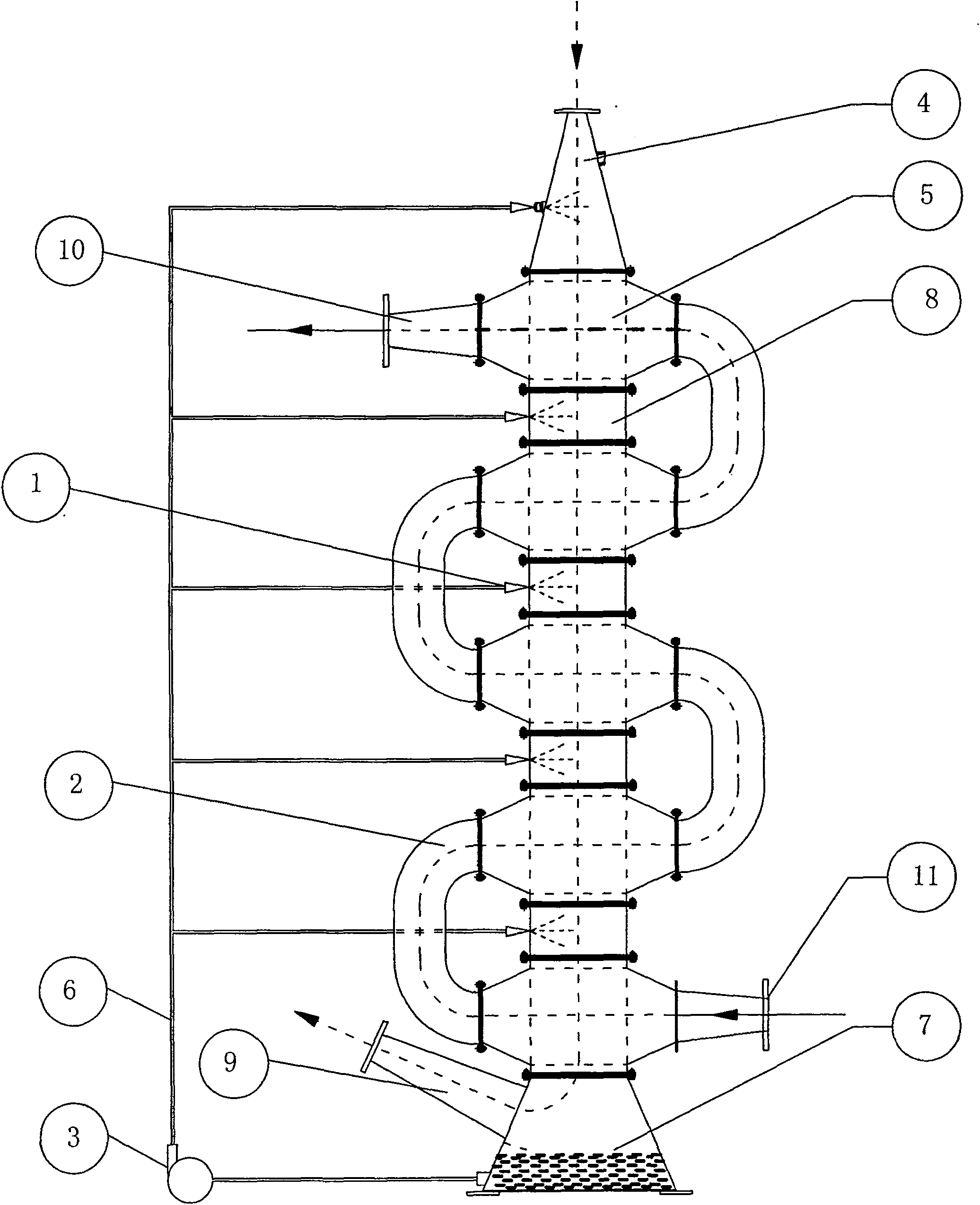

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

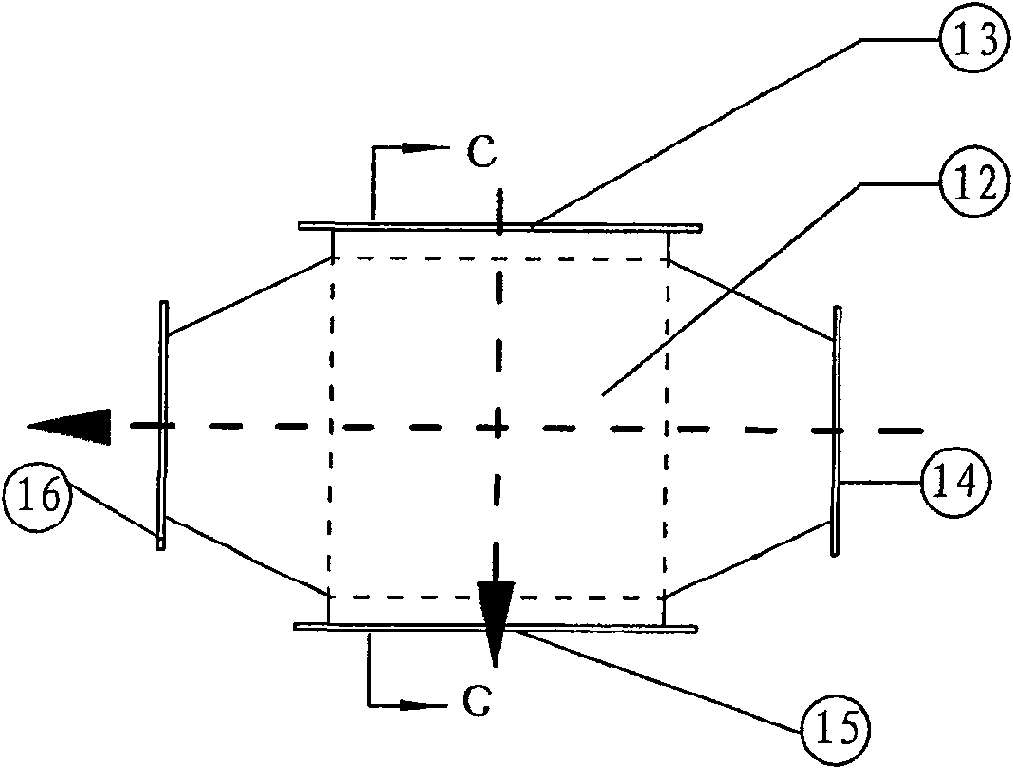

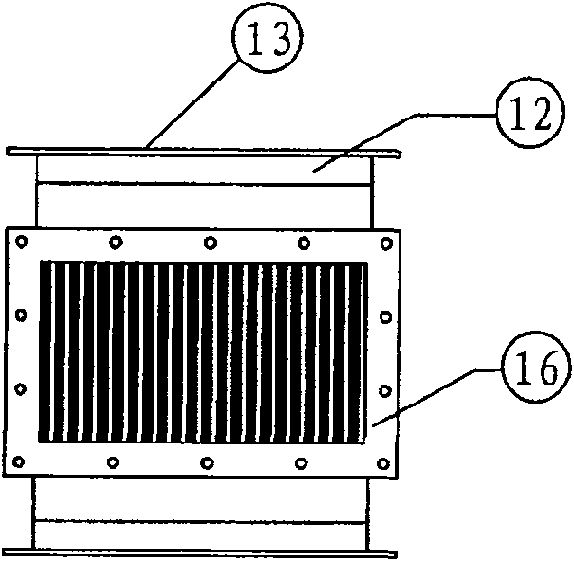

[0023] It includes a cooling air pipeline and a cooling air pipeline, and the two channels are not connected to each other, and each takes its own path. The cooling air pipeline is composed of 3 to 6 cold sides of heat exchange units 5 connected in series with the pipelines. In this embodiment, there are 5 heat exchange units, and each heat exchange unit is vertically arranged at intervals. The air inlet and outlet ends are connected by diversion elbow 2 and are connected in series with each other. One end of the bottom heat exchange unit is connected to the hot side air inlet pipe 11, which is the hot side air inlet end, and one end of the uppermost heat exchange unit is the hot side. The air outlet is connected to the hot side air outlet pipe 10 to form a cooling air pipeline; the heat exchange unit 5 is a plate-fin heat exchange unit, including a shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com