Heat exchanger, especially gas cooler

A heat exchanger and gas cooling technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve problems such as increasing the manufacturing cost of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

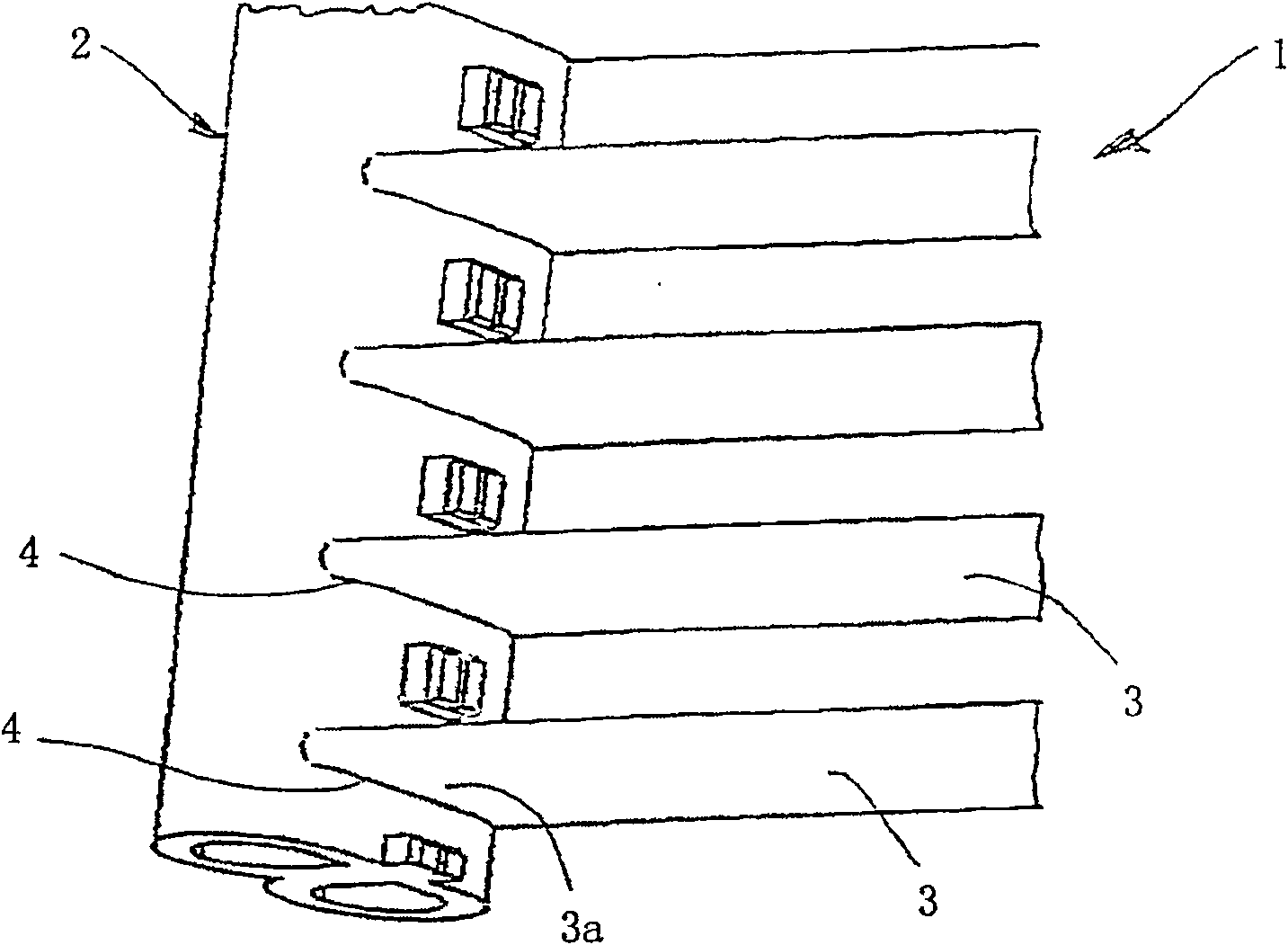

[0021] figure 1 A section of a gas cooler 1 is shown with a collector 2 and flat tubes 3 , the ends 3 a of which lead into the collector 2 and engage in slot-shaped openings 4 . Corrugated fins (not shown) are arranged between the flat tubes 3 to increase the heat exchange area with the air. The gas cooler 1 is especially suitable for use with CO 2 It is used as a refrigerant in the refrigerant cycle of automobile air-conditioning equipment, and of course its use is not limited to this. Mainly gaseous CO at a pressure of about 120 bar 2 The air flows through the gas cooler, ie in the collectors and flat tubes; secondly, the air brushes over the surface of the gas cooler. The gas cooler will CO 2 The temperature of the gas drops from about 150 degrees Celsius to 50 degrees Celsius. The pressure that occurs here is roughly equivalent to 10 times the pressure in the refrigerant cycle using R134a as the refrigerant in the traditional condenser.

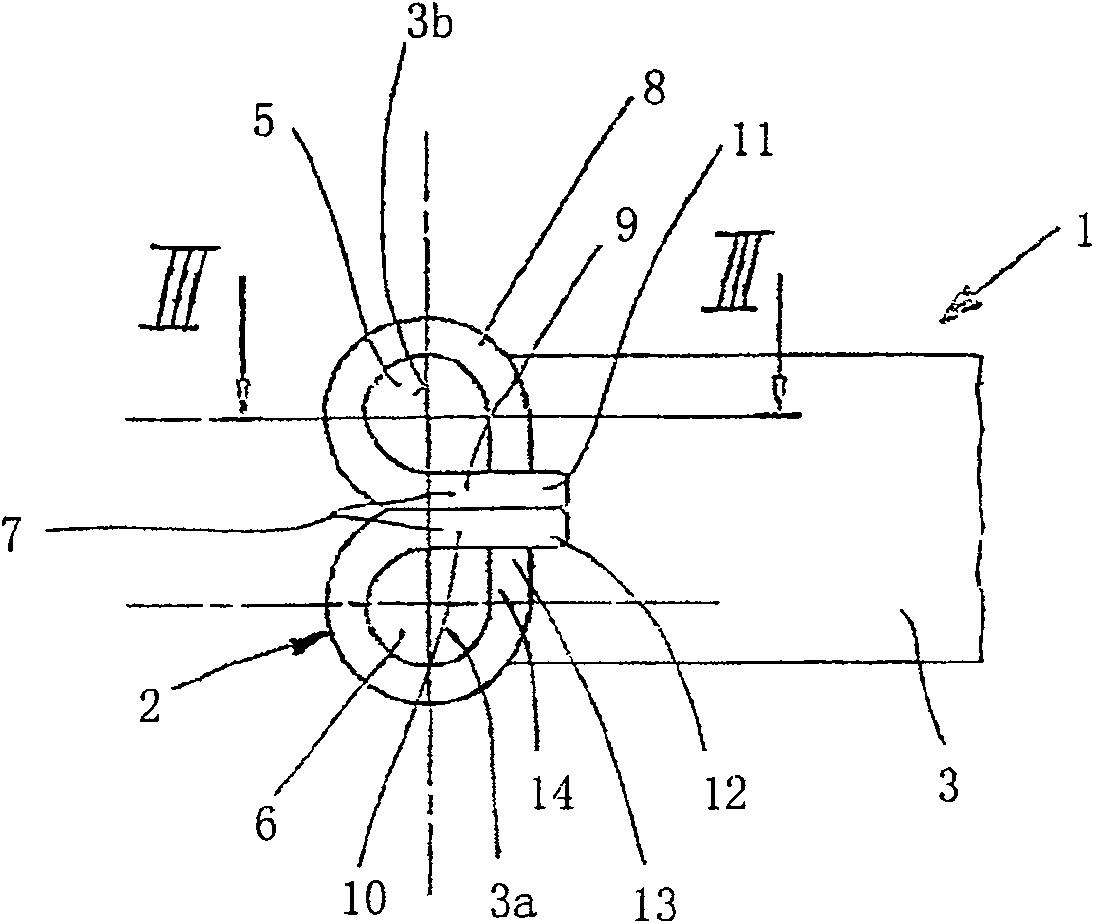

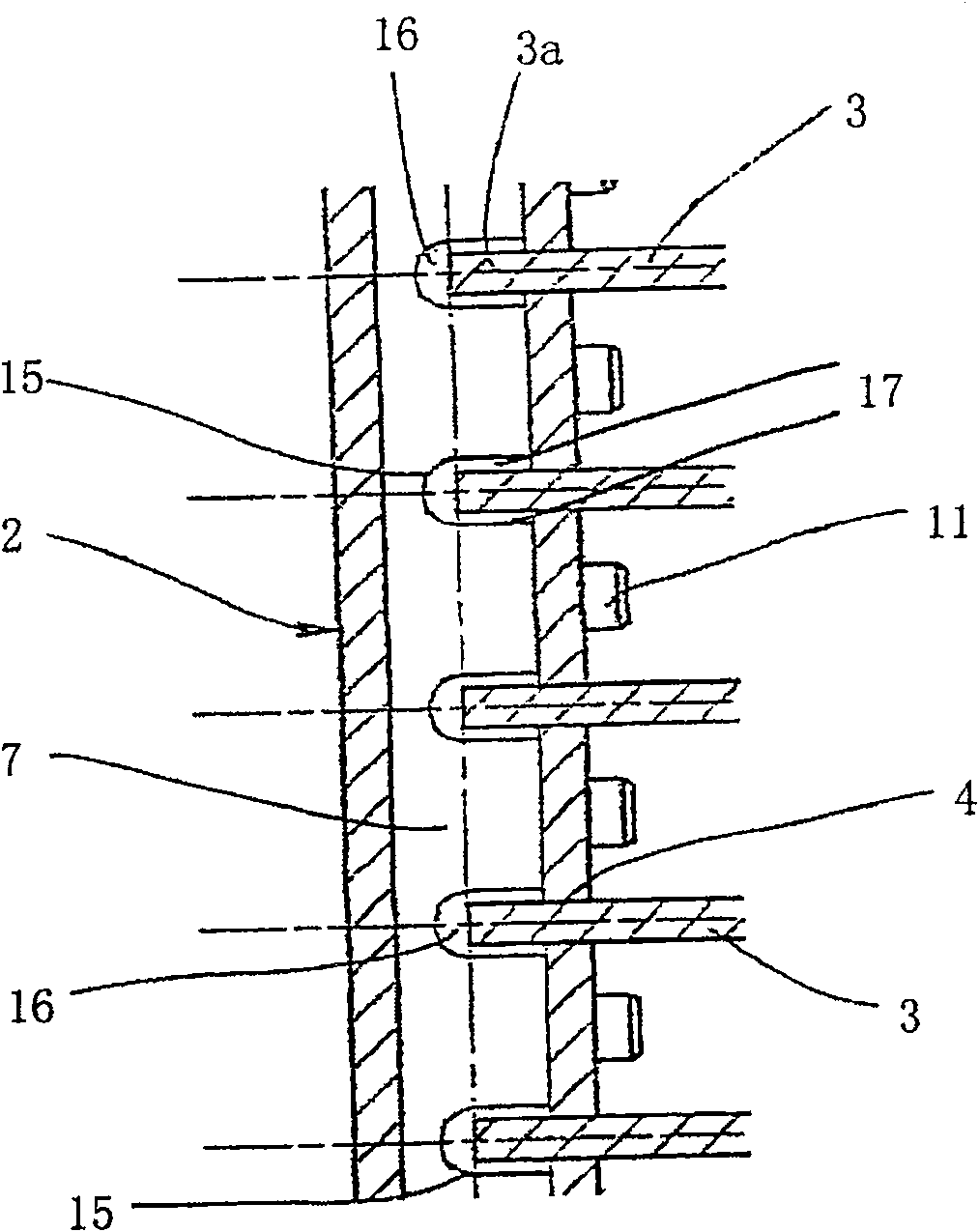

[0022] figure 2 for figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com