Full hydraulic electric forklift electric system

A technology for electric forklifts and electrical systems, applied in the direction of lifting devices, etc., can solve the problems of complex connection lines, large starting current, and large energy consumption, and achieve the effects of low starting energy consumption, lower energy consumption of the whole machine, and smooth state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

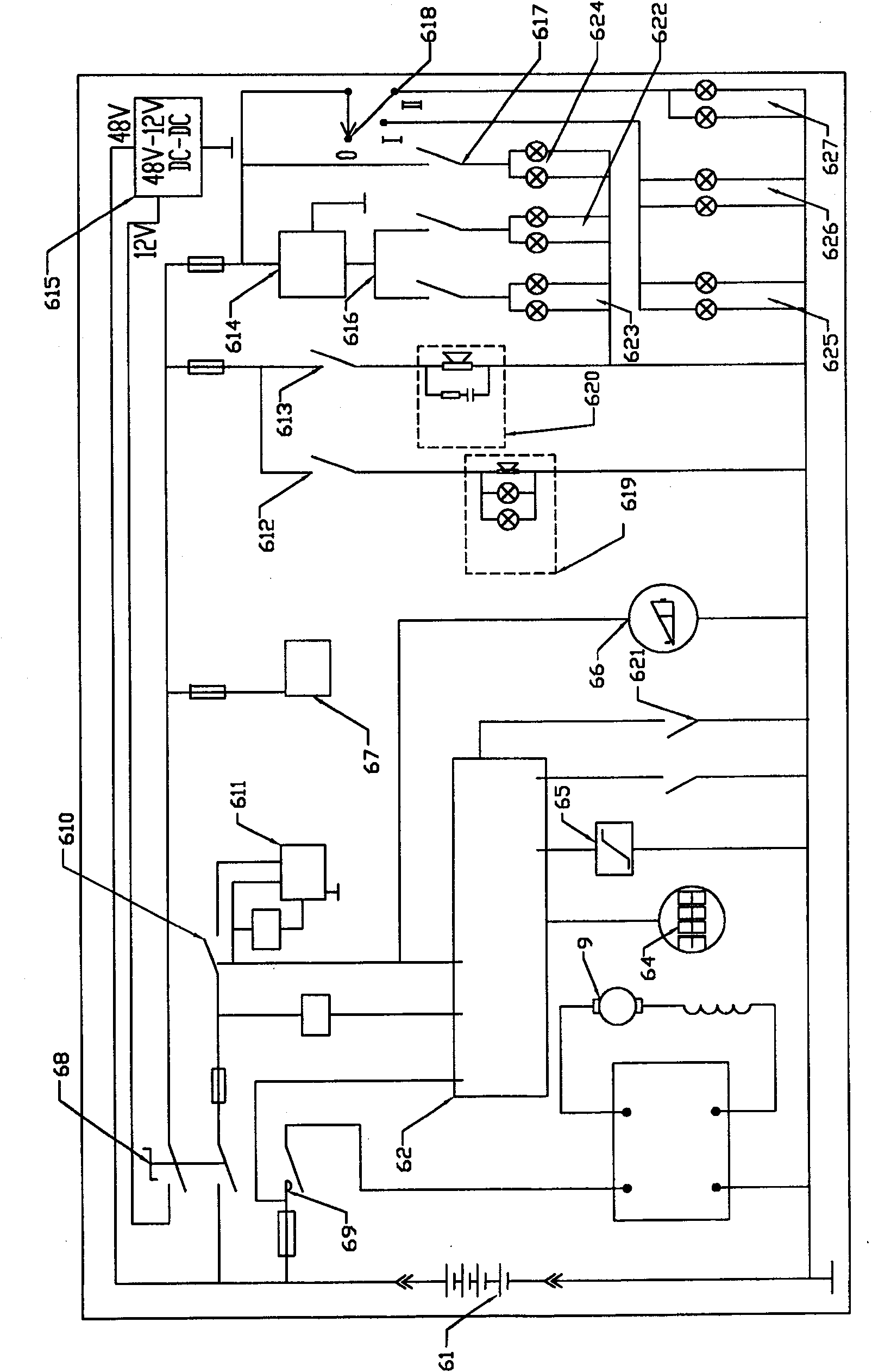

[0019] Such as figure 1 The electrical system of the fully hydraulic electric forklift shown includes battery power supply 61, key switch 68, a motor 9, and an acousto-optic system. The battery power supply 61 is used as an energy source to divide the power supply into high-voltage power supply and low-voltage power supply through a DC-DC transformer 615 for output: The low-voltage power supply connects the sound and light system through the key switch 68, a controller 62 mainly used for controlling the motor 9, and further connects the turning delay device 611 connected with the controller 62 through the start switch 610; the high-voltage power supply connects the controller 62 and is controlled by the main contactor 69 of the controller 62 to connect the motor 9, and the controller 62 is connected with an accelerator 65 and a micro travel switch 621. And: the excitation mode of motor 9 is series excitation, and the duty cycle is 60 minutes. A fault indicator 64 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com