Pile-roller up-rolling transfer type carding method and equipment

A transfer-type, carding technology, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of losing fiber humidity, affecting extraction rate, and difficult operation, so as to maintain fiber humidity, process adjustment is convenient, The effect of high fluff extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

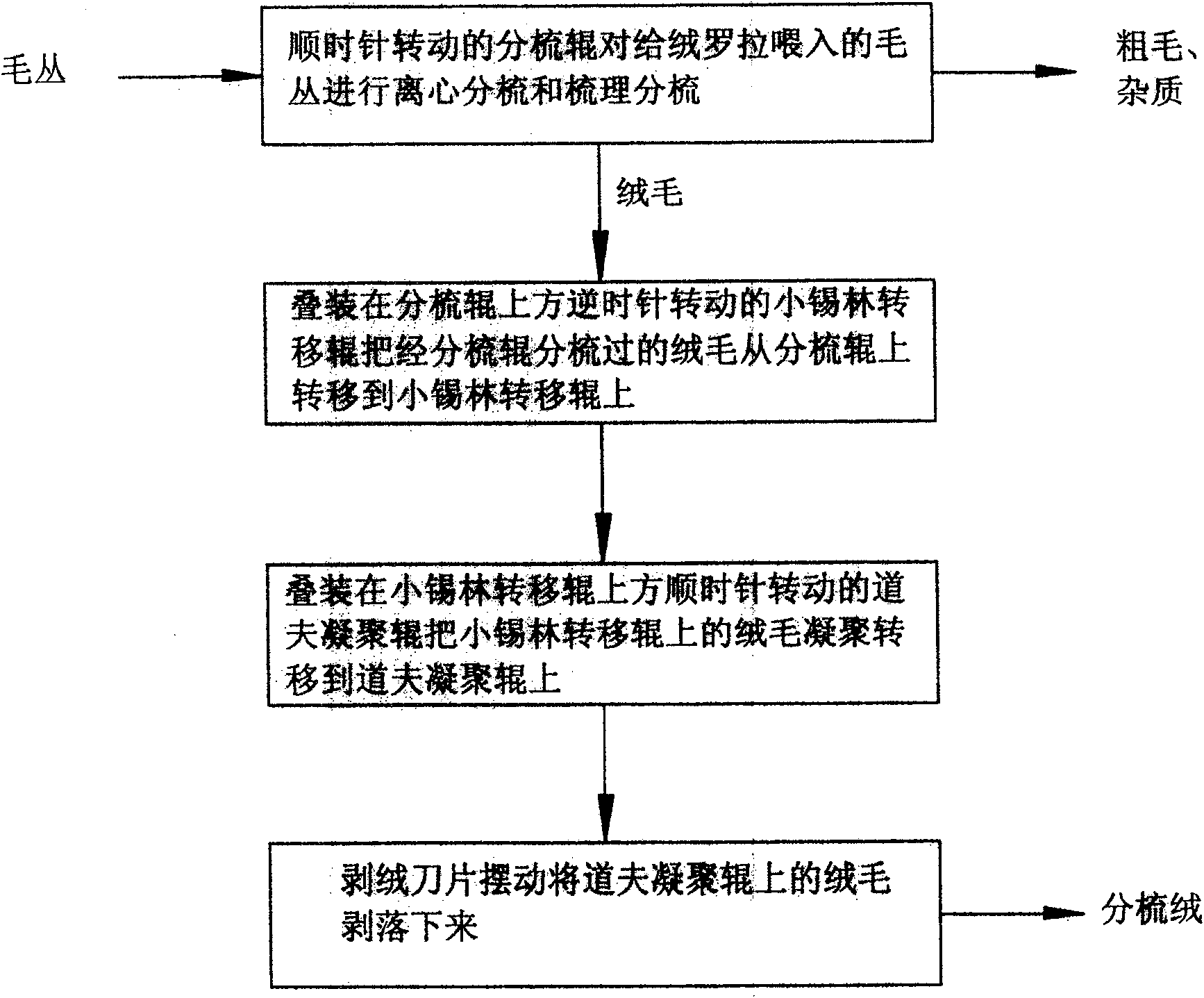

[0033] see figure 1 , a stacked roller upward transfer type carding method, the method is to stack the carding roller, small cylinder transfer, and doffer condensing roller sequentially from bottom to top, and the fluff after carding by the carding roller is from bottom to top Shift output up. Firstly, the carding roller rotating clockwise performs centrifugal carding and carding on the wool clump fed by the velvet roller to remove the coarse hair and impurities in the clump of wool. It runs upward; then the small cylinder transfer roller stacked above the carding roller and rotates counterclockwise will pick up the fluff hanging on the card clothing of the carding roller and transfer it upwards to the small cylinder transfer roller card clothing, and the fluff will follow The small cylinder transfer roller runs upward; then the doffer agglomeration transfer roller stacked on the top of the small cylinder transfer roller and rotates clockwise transfers the fluff agglomerated ...

Embodiment 2

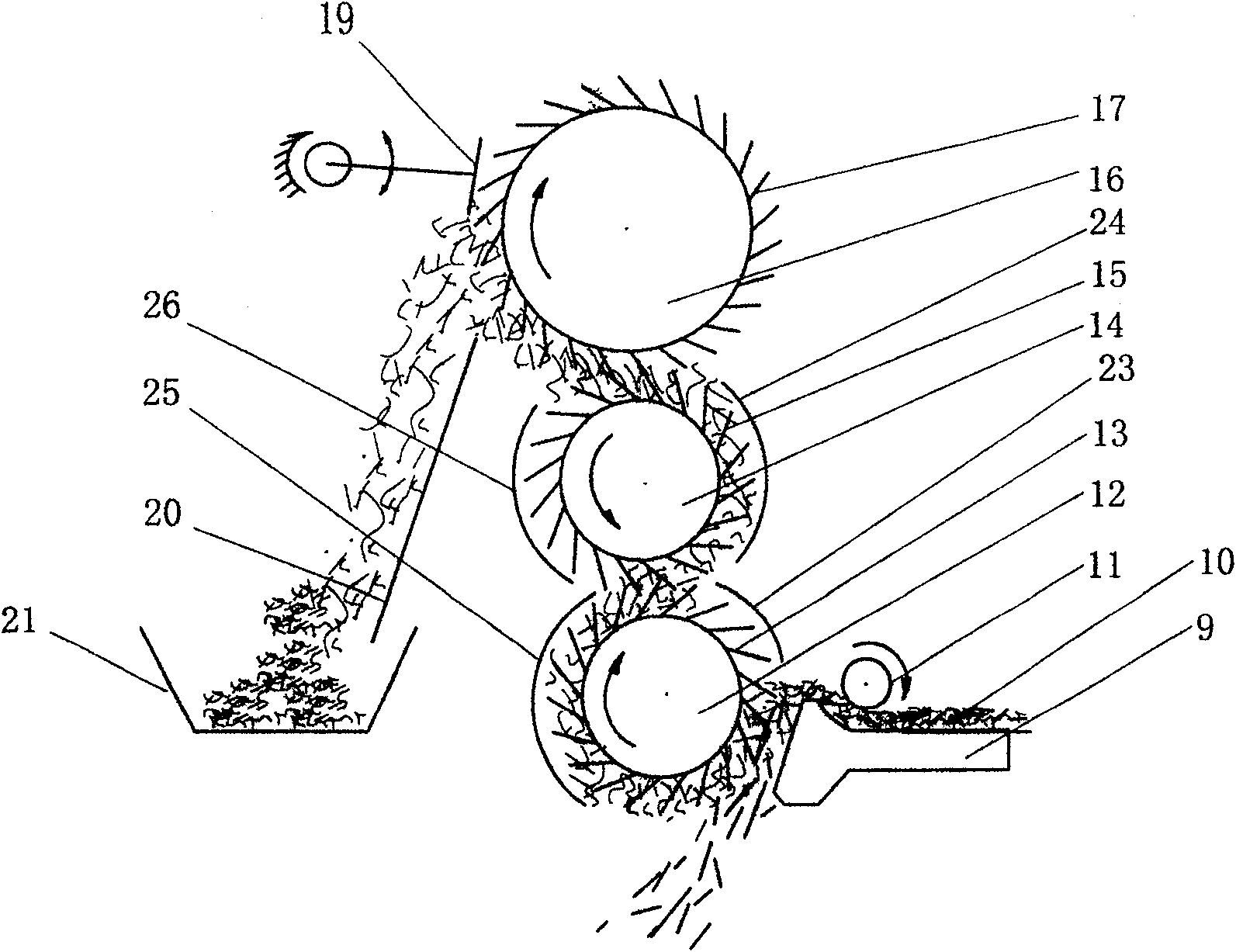

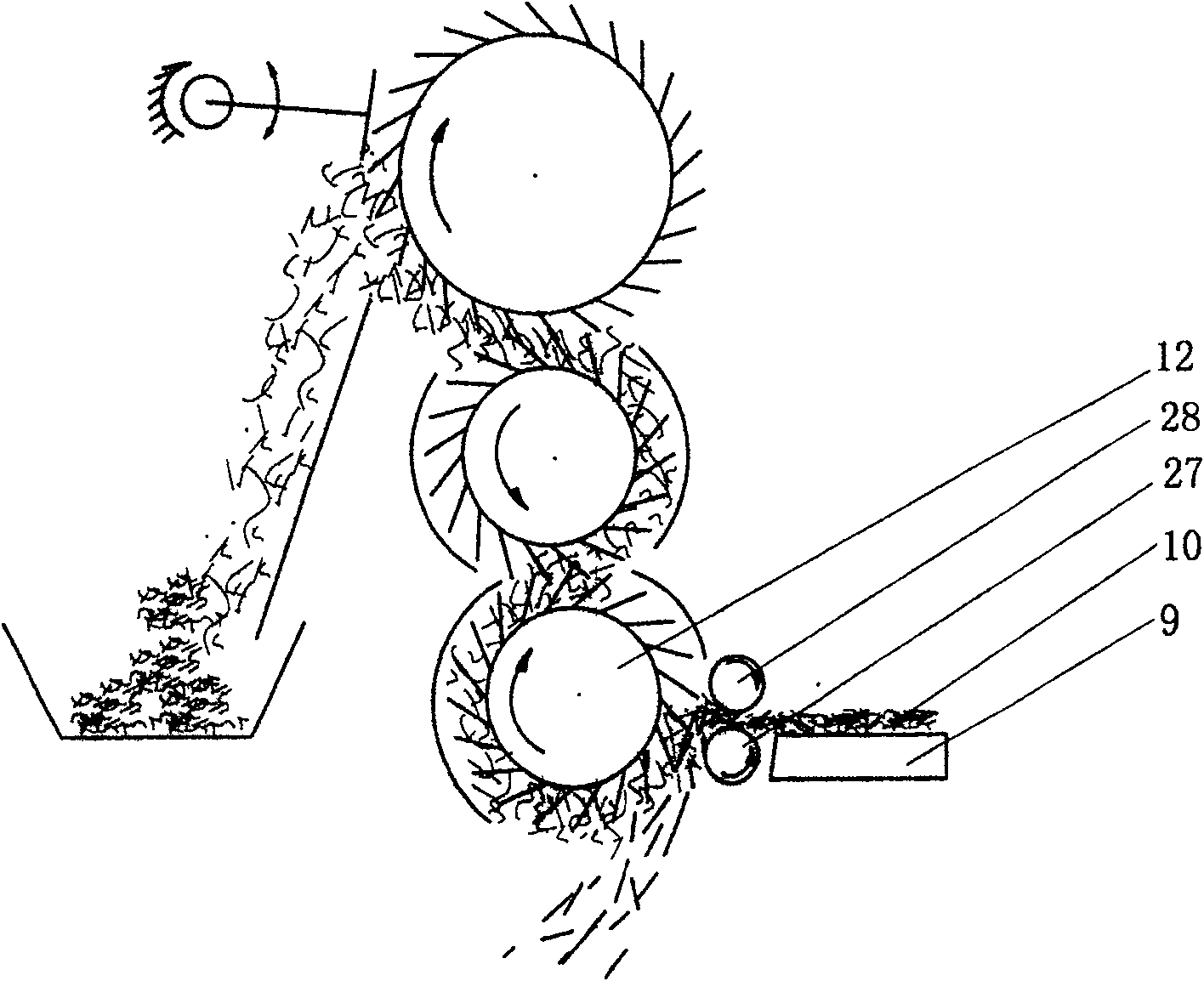

[0039] see figure 2 , a kind of upward stacking transfer type carding equipment, comprising a frame (not shown in the figure), a transmission mechanism (not shown in the figure), on the frame, carding rollers 12, A small cylinder transfer roller 14, a doffer condensing roller 16, and a cashmere feeding roller 11 are arranged in front of the carding roller 12; The front side; The frame is also provided with a swing type stripping suede blade 19, and this swing type stripped suede blade 19 is arranged on the doffer coagulation roller 16 rears.

[0040] Described transmission mechanism provides power transmission for the operation of carding roller 12, small cylinder transfer roller 14, doffer agglomeration roller 16, cashmere feeding roller 11, swing type stripping suede blade 19, and this transmission mechanism is prior art in this area, No longer.

[0041] In the present embodiment, a feeder roller 11 is installed in front of the opening roller 12, and the pile 10 is placed...

Embodiment 3

[0048] see figure 2 , on the basis of the technical scheme of embodiment 2, in order to protect the environment and avoid fluff flying off, the carding roller arc front cover 23 is equipped with the carding roller 12 in front, and the carding roller arc rear cover is equipped with at the carding roller rear Plate 25, small cylinder transfer roller arc-shaped front cover plate 24 and small cylinder transfer roller arc-shaped rear cover plate 26 are respectively provided with before and after the small cylinder transfer roller 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com