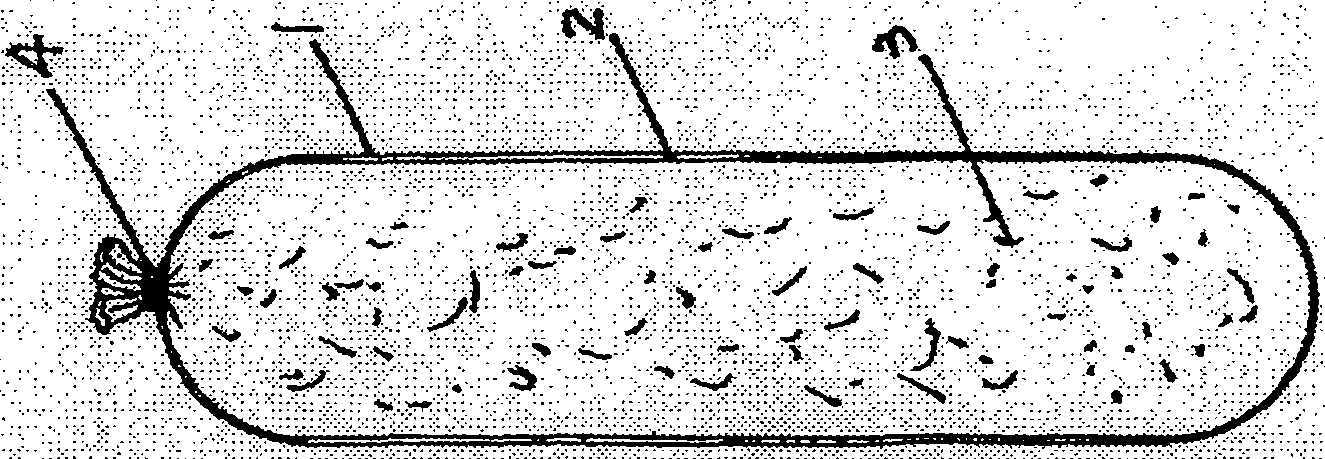

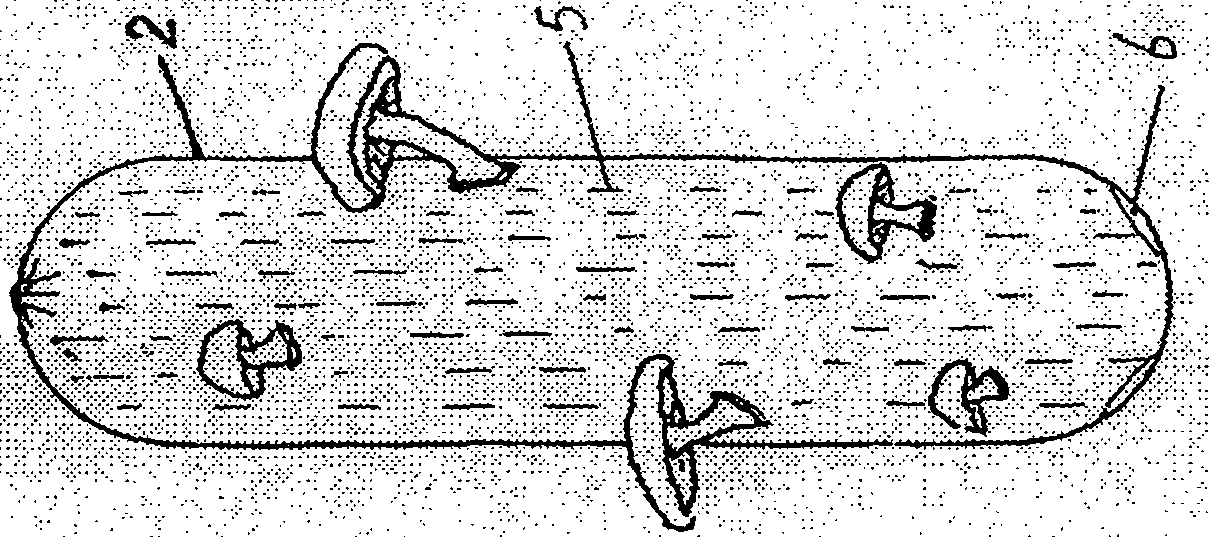

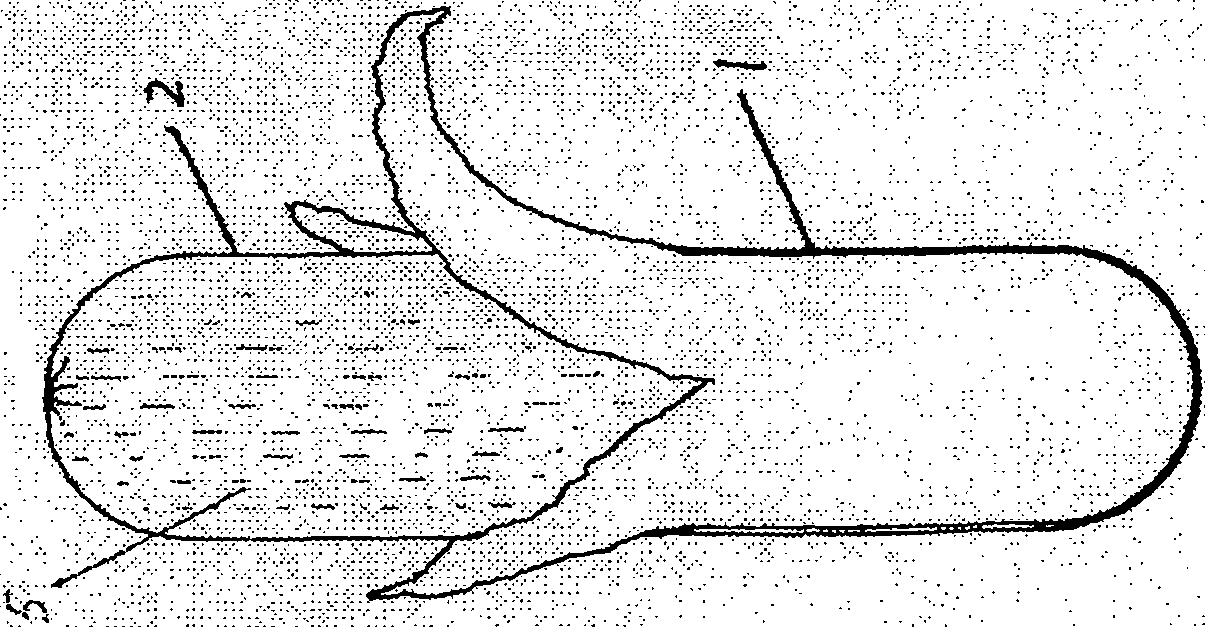

Zero-cutting moisture-holding cultivation bag of flower mushroom

A technology for hydroponics and flower mushrooms, which is applied in the fields of botanical equipment and methods, horticulture, and application, can solve the problems of self-drying and dying of mushroom buds, difficult water retention technology of mushroom sticks, and deformation of the top, so as to improve the shape, quality and naturalness. The effect of easy fruiting and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The flower mushroom cutting-free water-retaining cultivation bag of the present invention is composed of the following materials in weight percentage: 40%-70% of low-density polyethylene recycled material, 5%-20% of high-density polyethylene, 20%-20% of polyethylene filling masterbatch 45%, plastic photodegradable materials 1%-5%.

[0020] The weight percent of the optimum material components of the present invention is: 59% of low-density polyethylene regenerated material, 10% of high-density polyethylene, 29% of polyethylene filling masterbatch, and 2% of plastic photodegradable material.

[0021] Preparation process of the present invention:

[0022] a. Input the granules of various materials in the formula of the present invention into the mixer and stir evenly; b. Pour the above mixture into the film blowing machine to blow the film into shape. , the third zone is 200°C, the fourth zone is 190°C, and the fifth zone is 185°C; c. The plastic bag formed by blown film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com