Microwave heating method for water glass sand mold or sand core

A technology of water glass sand and water glass, which is applied in the field of sand mold hardening, which can solve the problems of high mold material requirements, easy moisture absorption of sand molds or sand cores, etc., and achieve high energy utilization, improved recyclability, and improved collapsibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

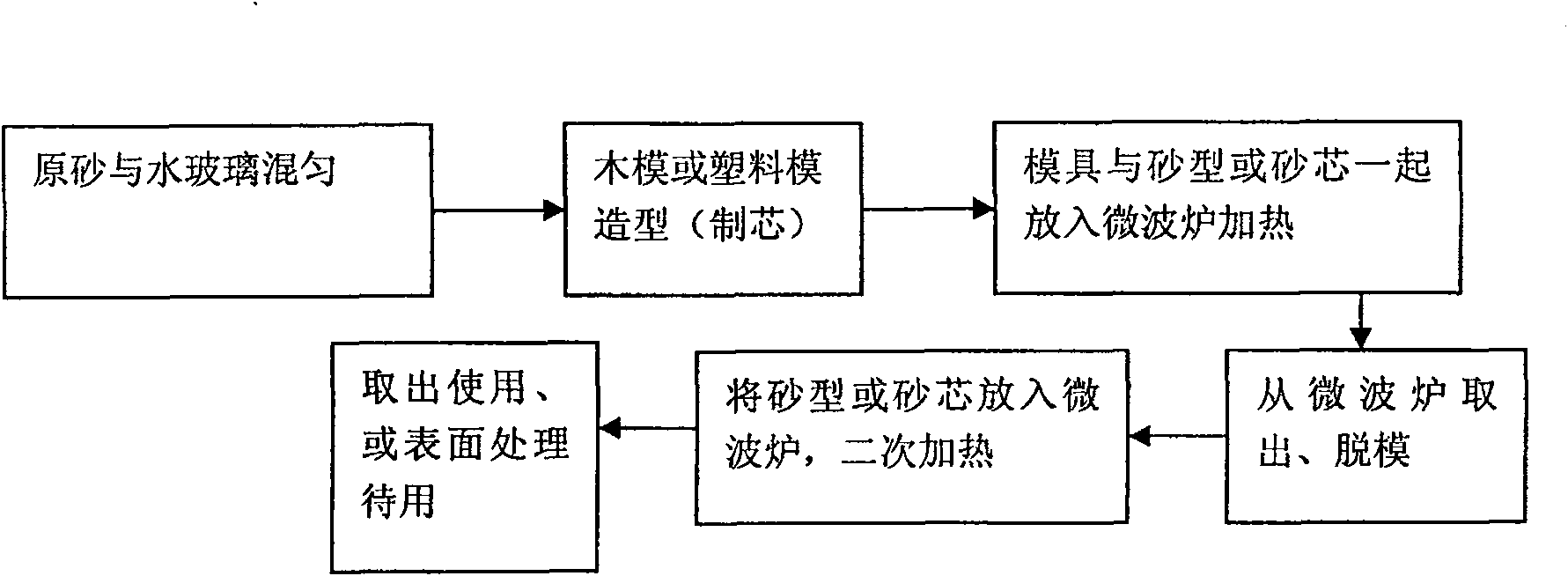

Method used

Image

Examples

Embodiment 1

[0030] (1) Molding core making step: add 1.5% casting water glass to the casting quartz sand, mix evenly, and adopt wooden mold molding;

[0031] (2) Heating step: put the sand mold together with the mold into a 2KW industrial microwave oven for heating, the heating time is 20 seconds, and its compressive strength reaches 28KPa;

[0032] (3) demoulding step: take out the heated sand mold together with the mold from the microwave oven, and demould;

[0033] (4) Secondary heating step: put the demolded sand mold into a 2KW industrial microwave oven for secondary heating, and heat it for 120 seconds to completely harden it to obtain a hardened sand mold with a compressive strength of 2.35MPa, which can be used directly in pouring.

Embodiment 2

[0035] (1) Molding and core making step: add 1.0% modified water glass for casting that has added a reinforcing agent to the casting quartz sand, mix evenly, and adopt plastic molding core;

[0036] (2) Heating step: put the sand mold together with the mold into a 10KW industrial microwave oven for heating, the heating time is 5 seconds, and its compressive strength reaches 17KPa;

[0037] (3) demoulding step: take out the heated sand core together with the mold from the microwave oven, and demould;

[0038] (4) Secondary heating step: put the sand mold after demoulding into a 10KW industrial microwave oven for secondary heating, and the heating time is 20 seconds to make it completely hardened to obtain a hardened sand core with a compressive strength of 0.75MPa. After taking it out of the microwave oven, apply moisture-proof paint and store it for later use.

Embodiment 3

[0040] (1) Molding core making step: add 2.5% cast water glass in cast limestone sand, mix evenly, adopt organic glass moulding;

[0041] (2) Heating step: put the sand mold together with the mold into a 500W household microwave oven for heating, the heating time is 60 seconds, and its compressive strength reaches 36KPa;

[0042] (3) demoulding step: take out the heated sand mold together with the mold from the microwave oven, and demould;

[0043] (4) Secondary heating step: put the demolded sand mold into a 500W household microwave oven for secondary heating, and heat it for 600 seconds to completely harden it to obtain a hardened sand mold with a compressive strength of 2.85MPa, which can be used directly in pouring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com