Glass lead-free pigment and method for preparing the same

A pigment and glass technology, applied in the field of glass lead-free pigments and its preparation, can solve the problems of dull patterns, poor acid and alkali resistance, increased workload, etc., achieve good decorative effects, enhance gloss, reduce Effect of Melting Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

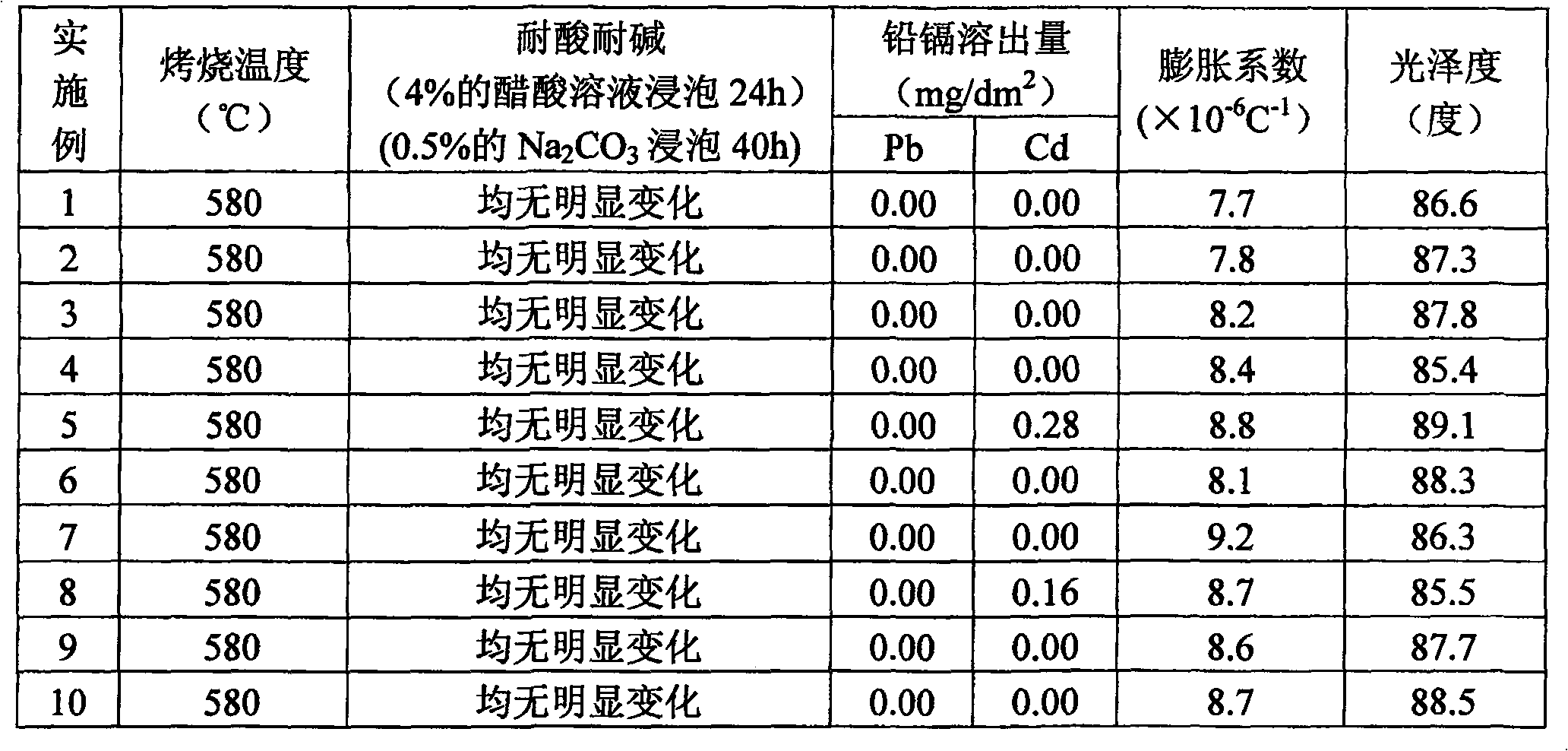

Examples

Embodiment 1

[0021] Embodiment 1: chrome green lead-free pigment

[0022] Components: It consists of 10% chrome green lead-free toner and 90% lead-free flux, wherein the weight percentage of flux is composed of: SiO 2 47.8%, B 2 o 3 17.7%, Al 2 o 3 0.5%, Li 2 O 4.1%, Na 2 O 5.7%, K 2 O 2.6%, BaF 2 2.8%, P 2 o 5 2.6%, Ta 2 o 3 0.5%, Nb 2 o 5 0.5%, ZrO 2 0.5%, CeO 2 1%, La 2 o 3 0.5%, Y 2 o 3 0.5%, ZnO 12.2%, MgO 0.5%.

[0023] Preparation method: Mix the raw materials of the solvent components passed through 40-80 mesh sieves, melt at high temperature, quench in cold water, dry and pulverize to above 100 mesh for later use; mix lead-free solvent and lead-free toner, and pass through airflow Pulverize to obtain chrome green lead-free pigment.

Embodiment 2

[0024] Embodiment 2: white lead-free pigment

[0025] The flux component content and preparation method are the same as those in Example 1, except that the white lead-free pigment consists of 15% white lead-free toner and 85% lead-free flux.

Embodiment 3

[0026] Embodiment 3: golden red lead-free pigment

[0027] The flux component content and preparation method are the same as those in Example 1, except that the golden red lead-free pigment is composed of 5% golden red lead-free toner and 85% lead-free flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com