Multicenter combustor nozzle

A burner, multi-channel technology, applied in the burner, combustion method, combustion type and other directions, can solve the problems of affecting the service life of refractory bricks, affecting the production operation rate, frequent ring formation in the rotary kiln, etc., and prolonging the formation time. , low noise, the effect of reducing the frequency of kiln shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

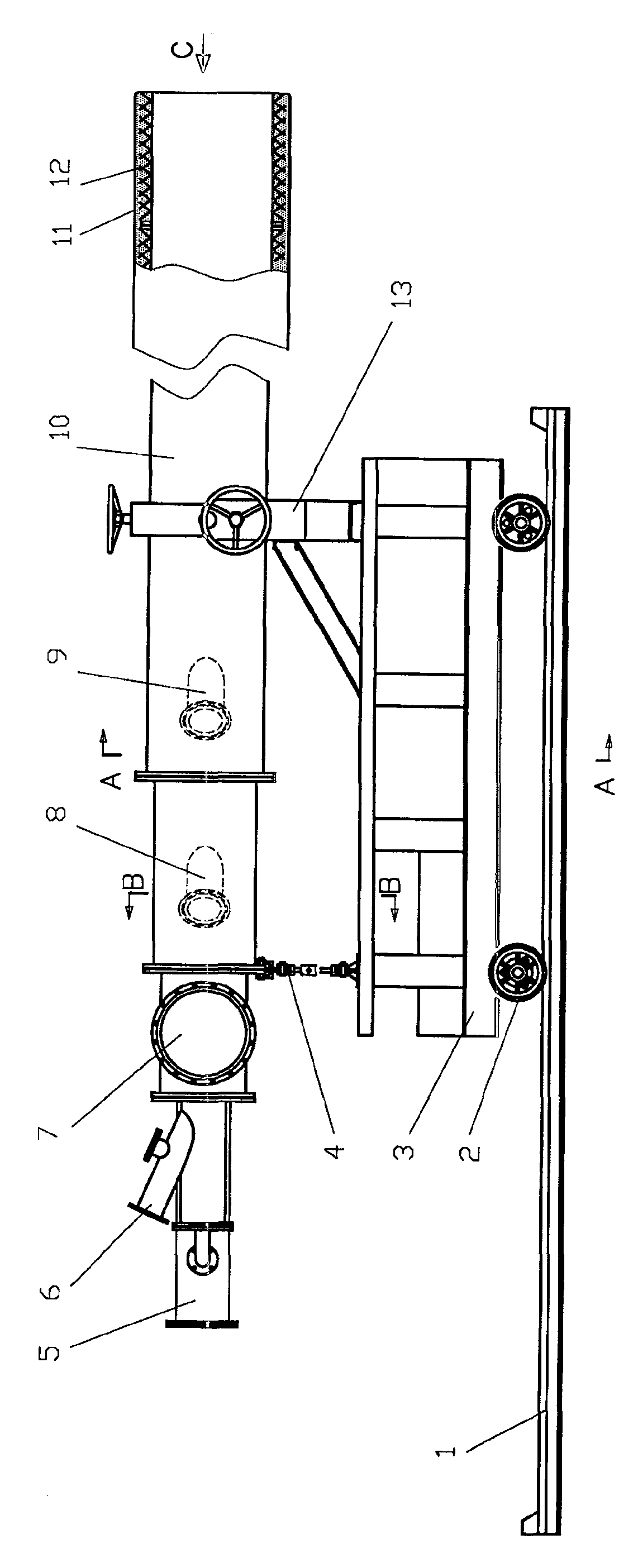

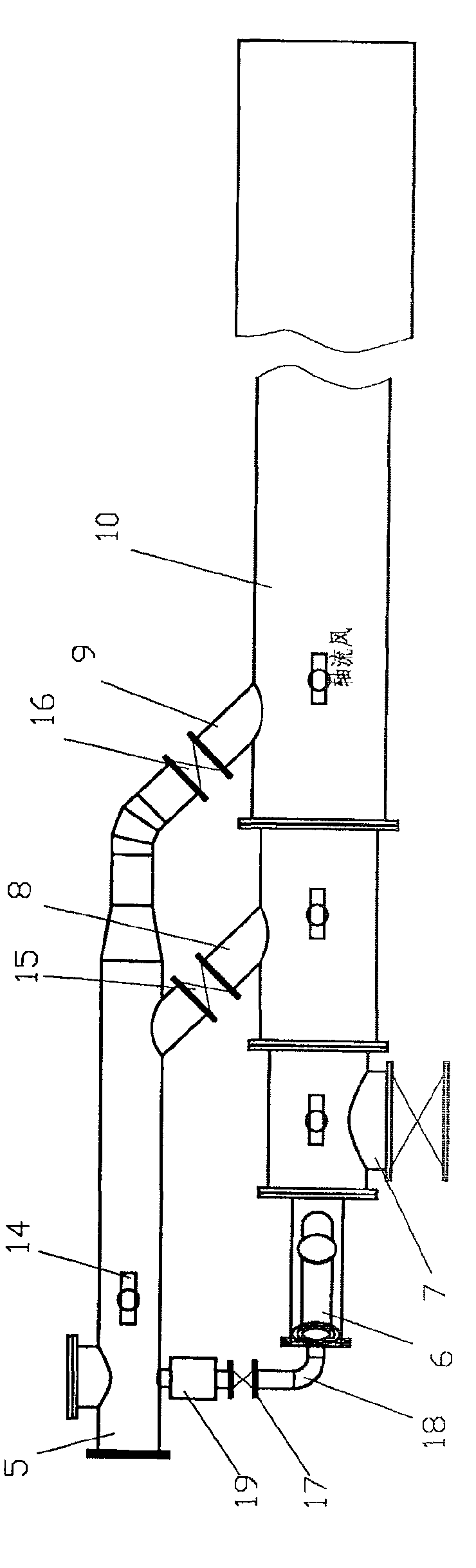

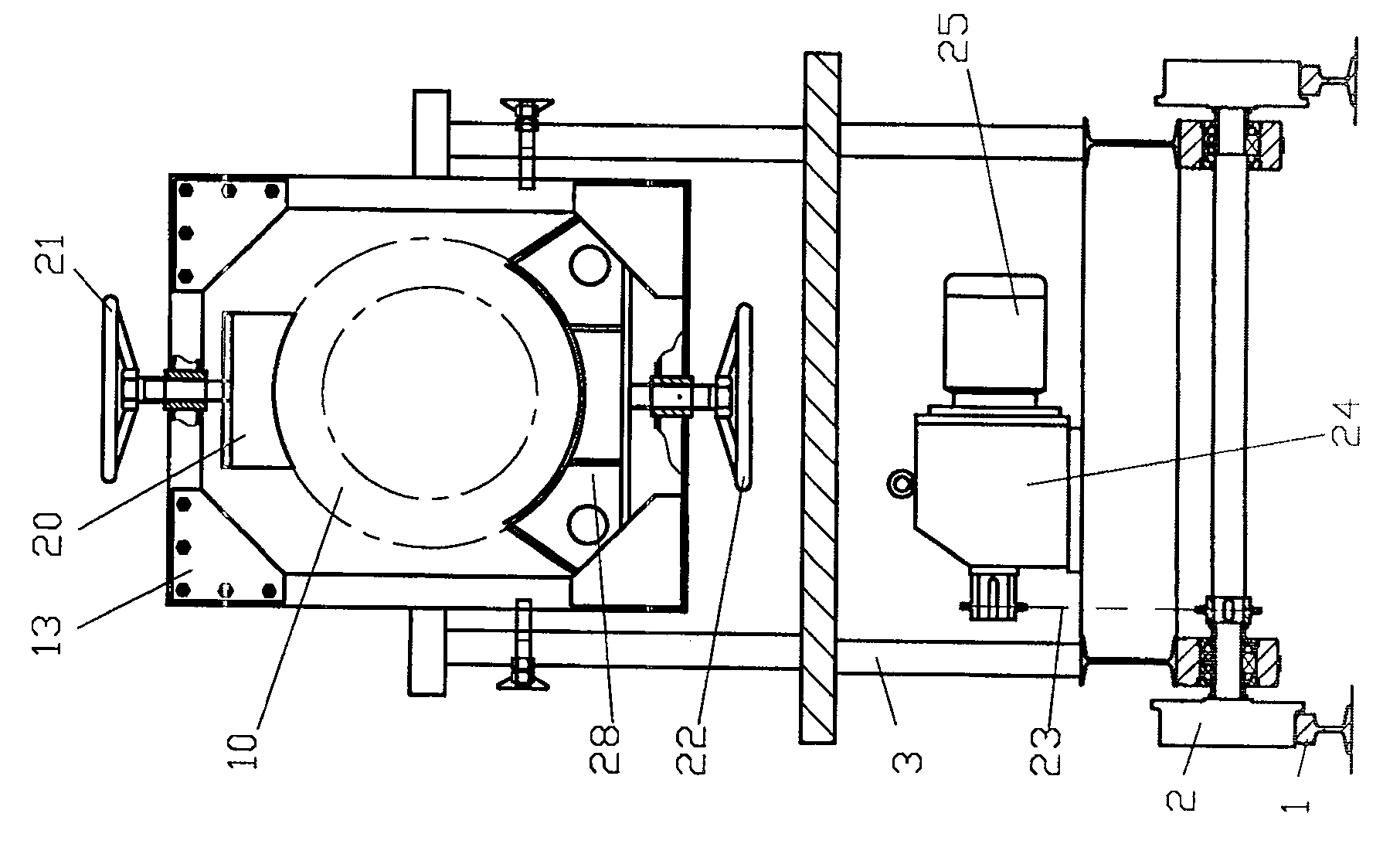

[0015] Such as figure 1 , 2 , 3, the trolley 3 sits on the guide rail 1 through the casters 2, the front and rear adjustment brackets 13 and rear adjustment brackets 4 are respectively fixed at the front and rear of the upper end of the trolley 3, and the front and rear adjustment brackets 13 and 4 support the burner body 10 . Fixed motor 25 on trolley 3, motor 25 drives caster 2 by speed reducer 24, sprocket wheel, chain 23. The upper and lower ends of the front end adjustment bracket 13 are respectively hinged to the upper pressure block 20 and the lower support block 28 through the upper and lower handwheels 21, 22; the rear end adjustment bracket 4 includes adjustable length left and right support columns 26 , 27, the upper ends of the left and right support columns 26, 27 are hinged with the burner body 10, and the lower ends are hinged with the trolley 3, as Figure 4 shown.

[0016] The structure of the burner body 10 is that multiple tubes are coaxially fitted toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com