LCD component manufacturing method

A technology of liquid crystal display and manufacturing method, applied in instrument, nonlinear optics, optics, etc., can solve problems such as difficult to control dose, poor thermal stability, high DC current of electrical characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

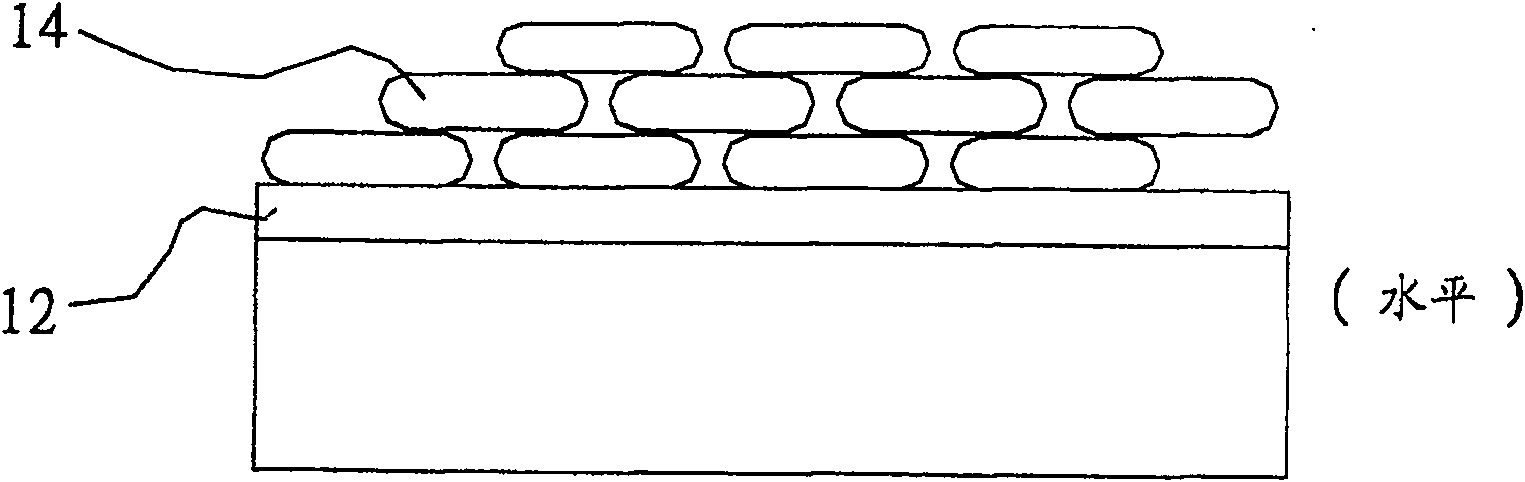

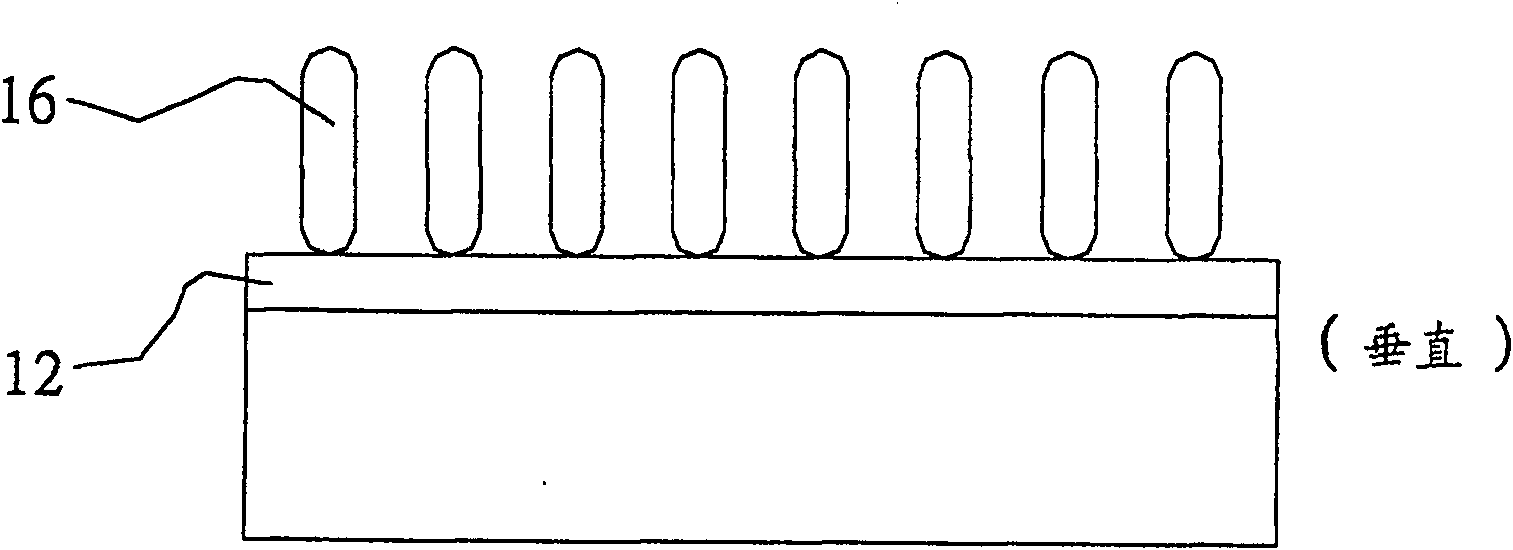

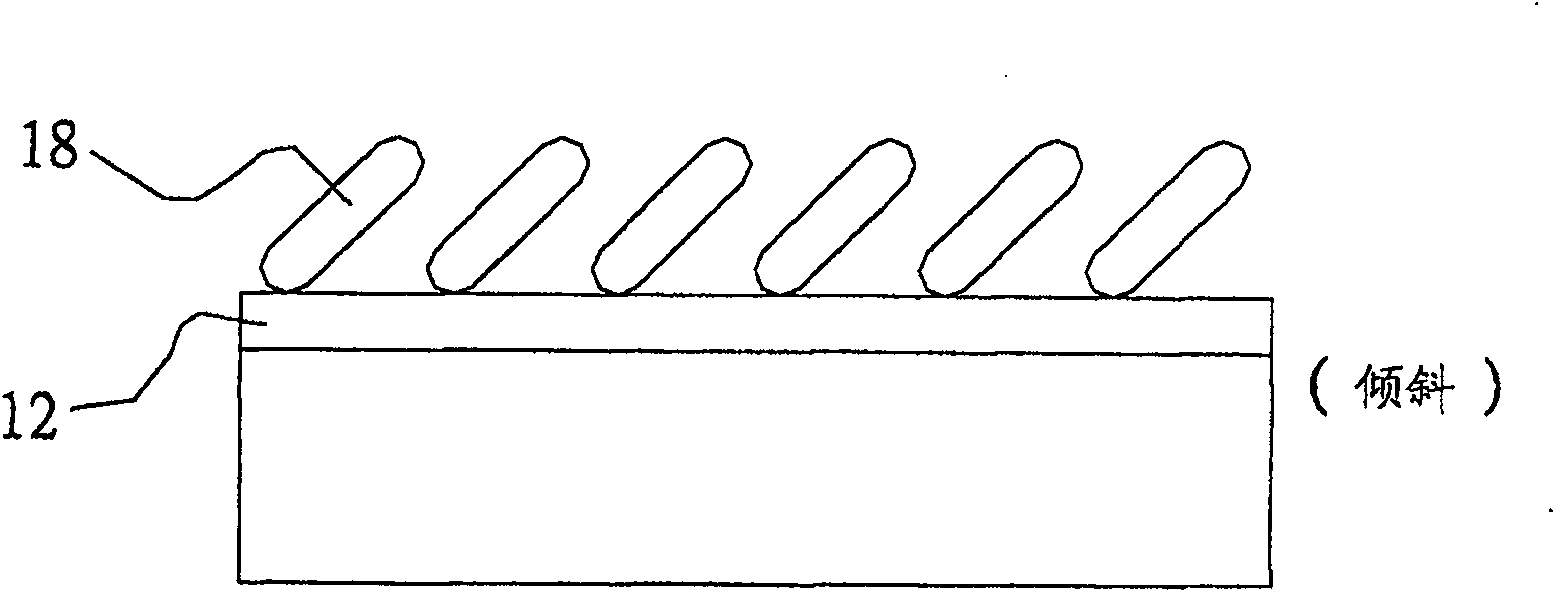

[0036] The present invention is a method for controlling the pretilt angle of liquid crystal molecules. In view of the fact that the pretilt angle of liquid crystal molecules in a liquid crystal display is related to the density of side chains (side chains) on the surface of an alignment film, the precisely adjustable plasma (plasma) or The particle beam generated by ions treats the surface of the alignment film of the liquid crystal display device, thereby adjusting the density of side chains on the surface of the alignment film, thereby changing the pretilt angle of the liquid crystal molecules. Moreover, unlike the known technology that needs to specially prepare and mix vertical and horizontal alignment films to achieve a higher pretilt angle, the present invention only requires a single vertical alignment film (including its materials and alignment film solution), and then applies the following detailed description The required surface treatment and alignment methods can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com