Pipe type straight line permanent magnet synchronous motor

A permanent magnet synchronous motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as difficult cooling and heat dissipation, unilateral magnetic pull increases motor power loss, temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

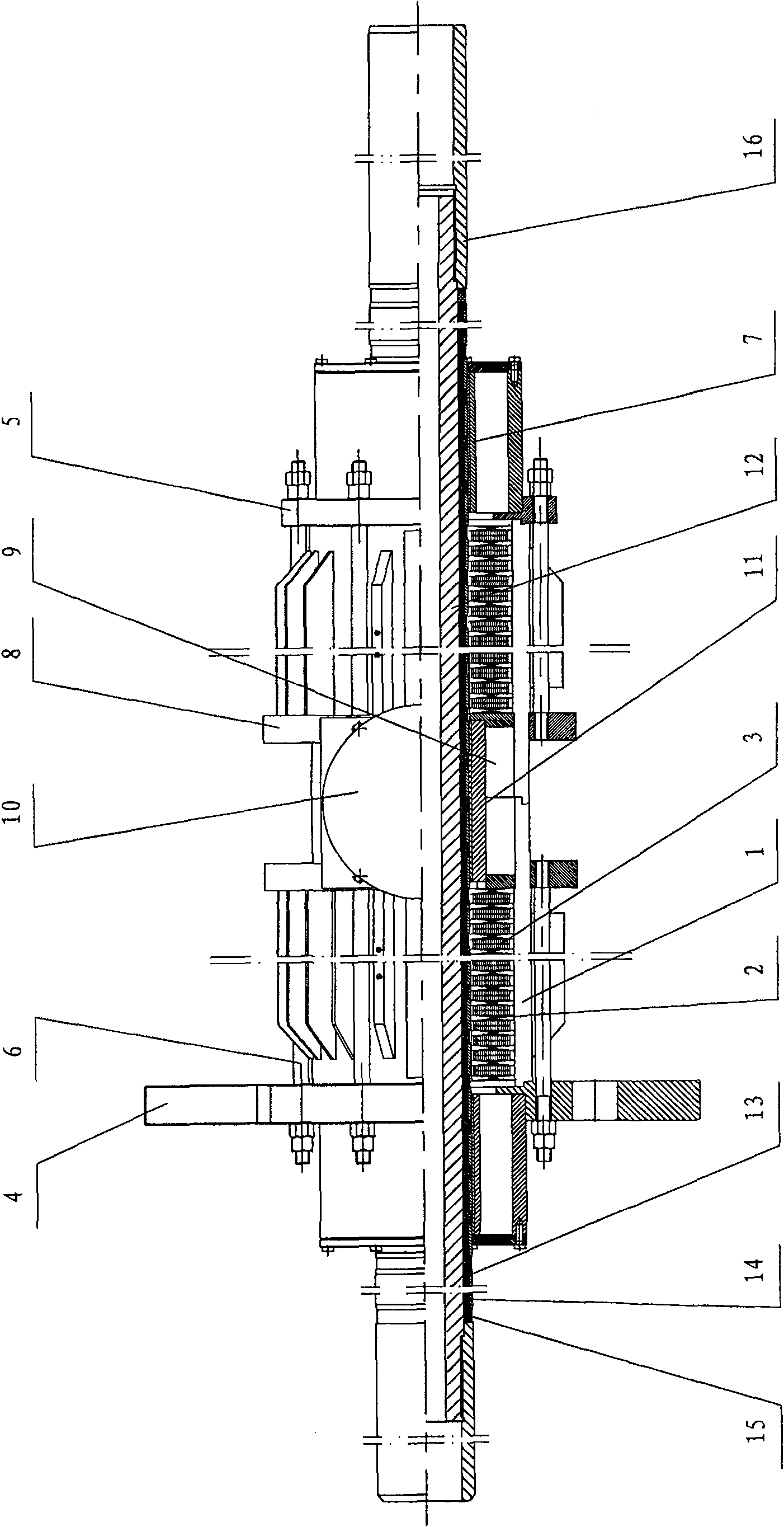

[0010] The present invention will be further introduced below in conjunction with the accompanying drawings: the present invention mainly includes primary and secondary poles. 3 are interlaced and installed in the casing, and are connected and press-fitted through the upper end cover 4, the lower end cover 5 and the screw rod 6 to form the primary part of the linear motor; It is made of resin casting; the upper end cover 4 and the lower end cover 5 are equipped with sliding bearings 7 and maintain the electromagnetic air gap between the primary poles. A fan 10 is installed symmetrically on the top of the blue, and a sliding bearing 11 is installed at the center in the middle of the casing.

[0011] In the present invention, a secondary steel pipe 12 is installed at the center of the primary part, and its outer wall is equidistantly inlaid with a plurality of tile magnets 13, and the tile magnets are covered with annular pole shoes 14, and the tile magnets 13 are radial For ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com