Synchronous valve in use for brake system

A brake system and synchronous valve technology, applied in the direction of pipeline layout, etc., can solve the problems that residual air cannot be discharged, the brake system and synchronous valve cannot work safely and reliably, and achieve improved braking performance, simple structure and reliability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

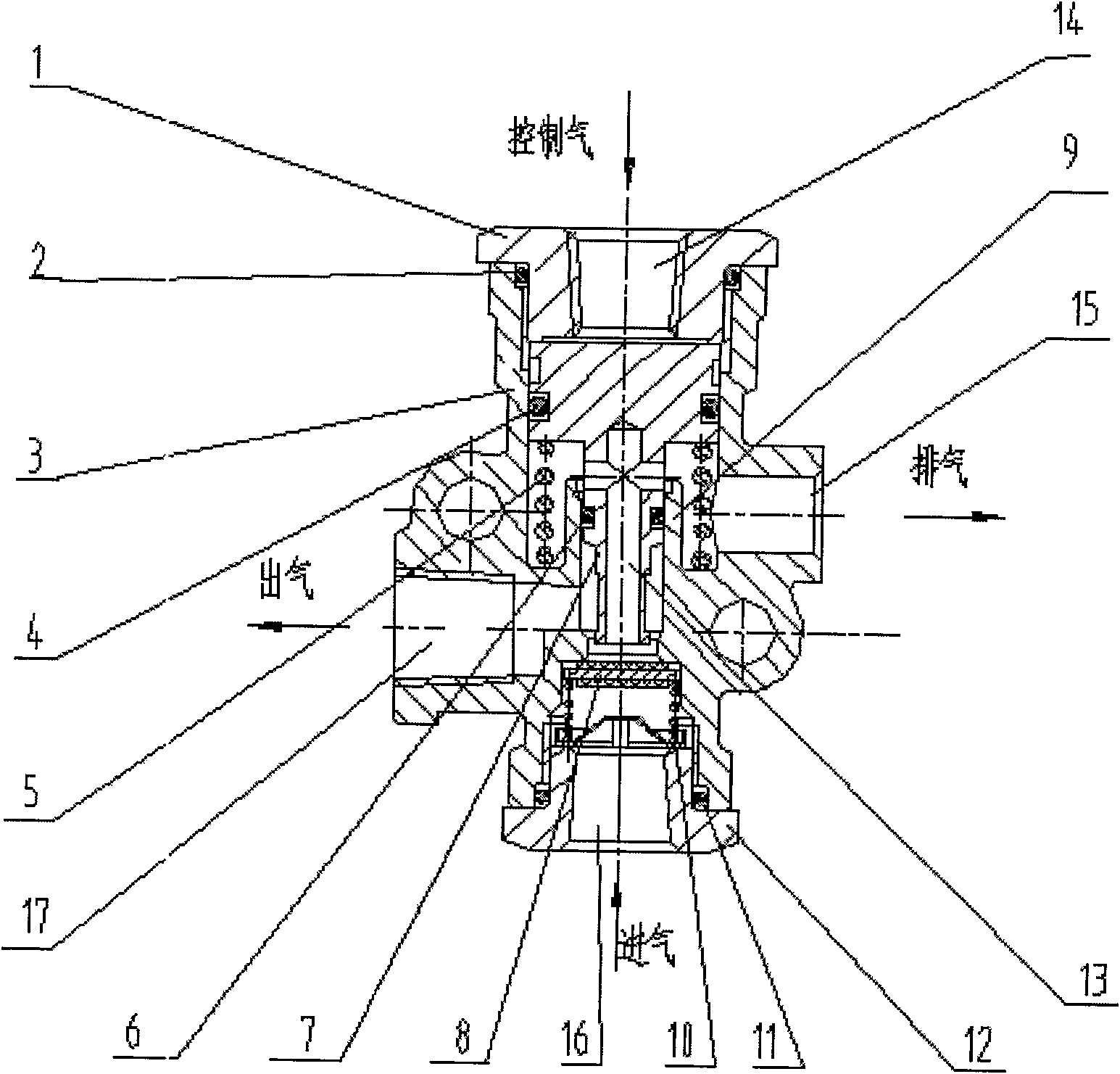

[0013] exist figure 1 Among them, a synchronous valve includes a valve body 3, on which there is an air inlet 16, an air outlet 17 and a control air port 14; an air inlet valve is arranged in the valve body 3 at one end of the air inlet 16; The air valve is opened, and the air inlet 16 is connected with the air outlet 17; the piston 7 that controls the work of the air inlet valve is arranged in the valve body 3 at one end of the control air port 14, and the upper stroke dead point of the piston 7 is adjustable and tightened on the control air port end. The control air port screw plug 1 is limited, the downstroke dead point of the piston 7 is on the inner step 9 of the valve body 3 at the control air port end, and the bottom of the piston 7 and the bottom of the valve body 3 at the control air port end press the return spring 5; fit on the valve body 3 Discharge port 15 is also provided with piston 7 return spring 10 position, and air passage 13 is also provided with in piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com