Photoreceptor with overcoat layer

A technology of outer coating and imaging element, applied in optics, instruments, electrographics, etc., can solve the problems of prone to cracking and reducing the useful life of photoreceptors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

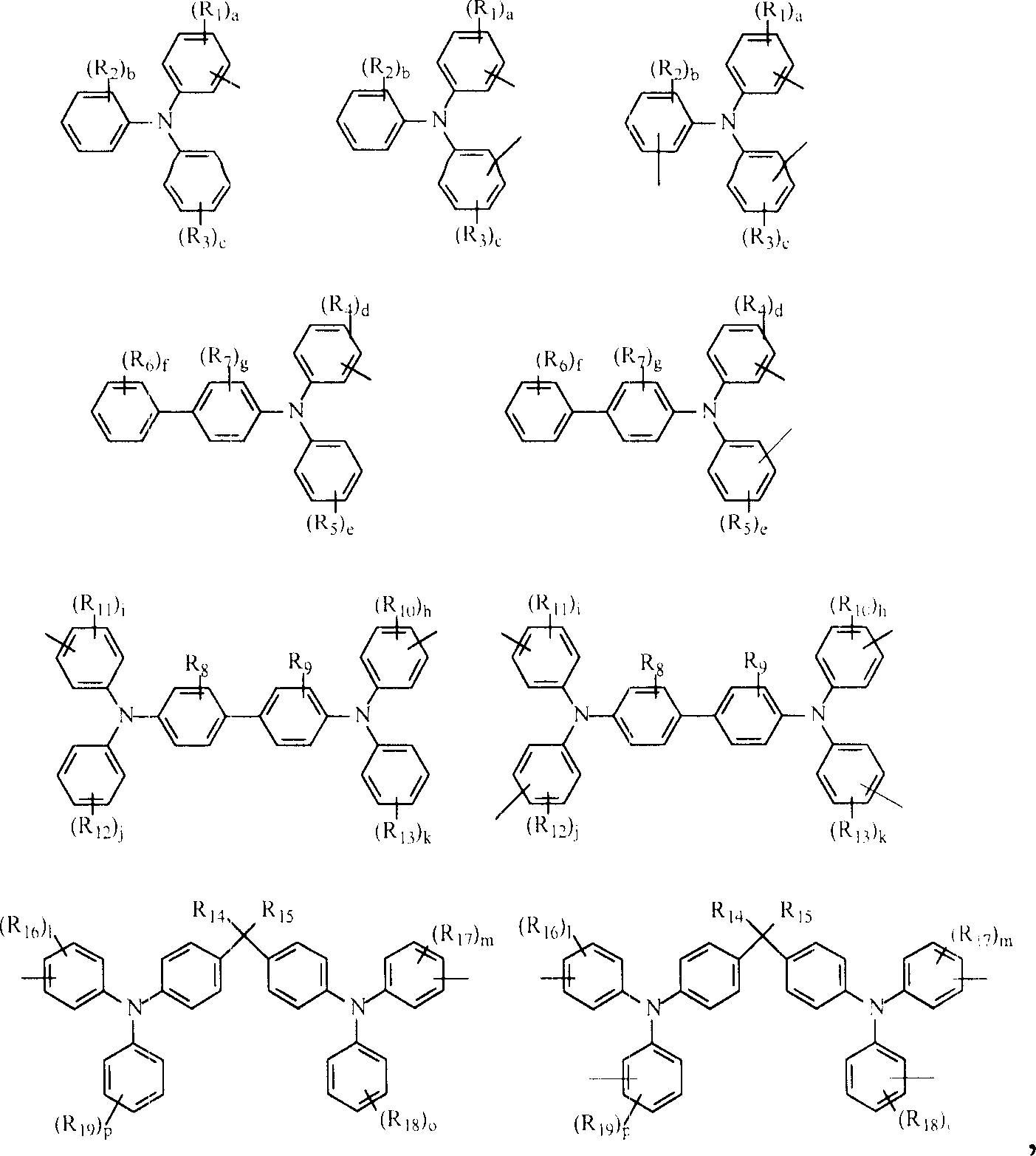

[0143] Example 1 - Preparation of Hydroxyl-Containing Hole Transport Compounds:

[0144]The hydroxyl-containing hole transport compound N,N-bis(4-hydroxymethylphenyl)-3,4-dimethylphenylamine was prepared as follows:

[0145]

[0146] N,N-Bisphenyl-3,4-dimethylphenylamine is prepared by the known Ulmann condensation process.

[0147] A mixture of N,N-bisphenyl-3,4-dimethylphenylamine (162 g), zinc chloride (80.76 g), DMF (129.94 g) and Isopar L (222 g) was added to the 3-L RB (round bottom) flask. Phosphorus oxychloride (272.62 g) was added dropwise to the reaction mixture under argon with stirring. The reaction mixture was heated to 120°C and maintained at this temperature for 12 hours. Then about 500 g of N,N'-dimethylformamide was added to the obtained mixture. The reaction mixture was cooled to about 50°C and poured into 2.5 L of water with mechanical stirring. The precipitate obtained was collected by filtration and washed twice with water (2 L) and then refluxed...

Embodiment 2

[0149] Example 2 - Preparation of Overcoat Composition:

[0150] A coating composition was formed comprising: 1 gram of DESMOPHEN(R) 800 polyester polyol, 0.6 gram of Cymel 1130, 0.8 gram of the hole transport molecule N,N-bis(4-hydroxymethylphenyl)-3 of Example 1 , 4-dimethylphenylamine, 7.2 grams of 1-methoxy-2-propanol (DowanolPM) and 0.2 grams of p-toluenesulfonic acid / pyridine (8% acid / 4% pyridine in 1-methoxy base-2-propanol). The components are mixed and shaken at room temperature (about 20°C to about 25°C) until all components are dissolved.

Embodiment 3

[0153] Example 3 - Preparation of Overcoated Imaging Elements:

[0154] Overcoated imaging element sheets or tapes were formed using the coating composition of Example 2. Specifically, electrophotographic imaging element web stock was prepared by providing a biaxially stretched polyethylene naphthalate substrate (Kadalex, available from ICI Americas, Inc.) at a thickness of 3.5 mils (89 microns). ) was coated with a 0.02 micron thick layer of titanium and applied using the gravure coating technique containing 10 grams of gamma-aminopropyltriethoxysilane, 10.1 grams of distilled water, 3 grams of acetic acid, 684.8 grams of 200 anti-denatured alcohol and 200 g of heptane. This layer was then allowed to dry in a forced air oven at 135°C for 5 minutes. The dry thickness of the barrier layer obtained was measured with an ellipsometer to be 0.05 microns.

[0155] The adhesive interface layer was then prepared by applying to the barrier layer a wet coating comprising 5 wt% poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap