Warp-runner triple layer fabric with paired intrinsic warp binders

A fabric and warp technology, applied in the field of papermaking, can solve problems such as damage to the forming layer paper, fabric breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

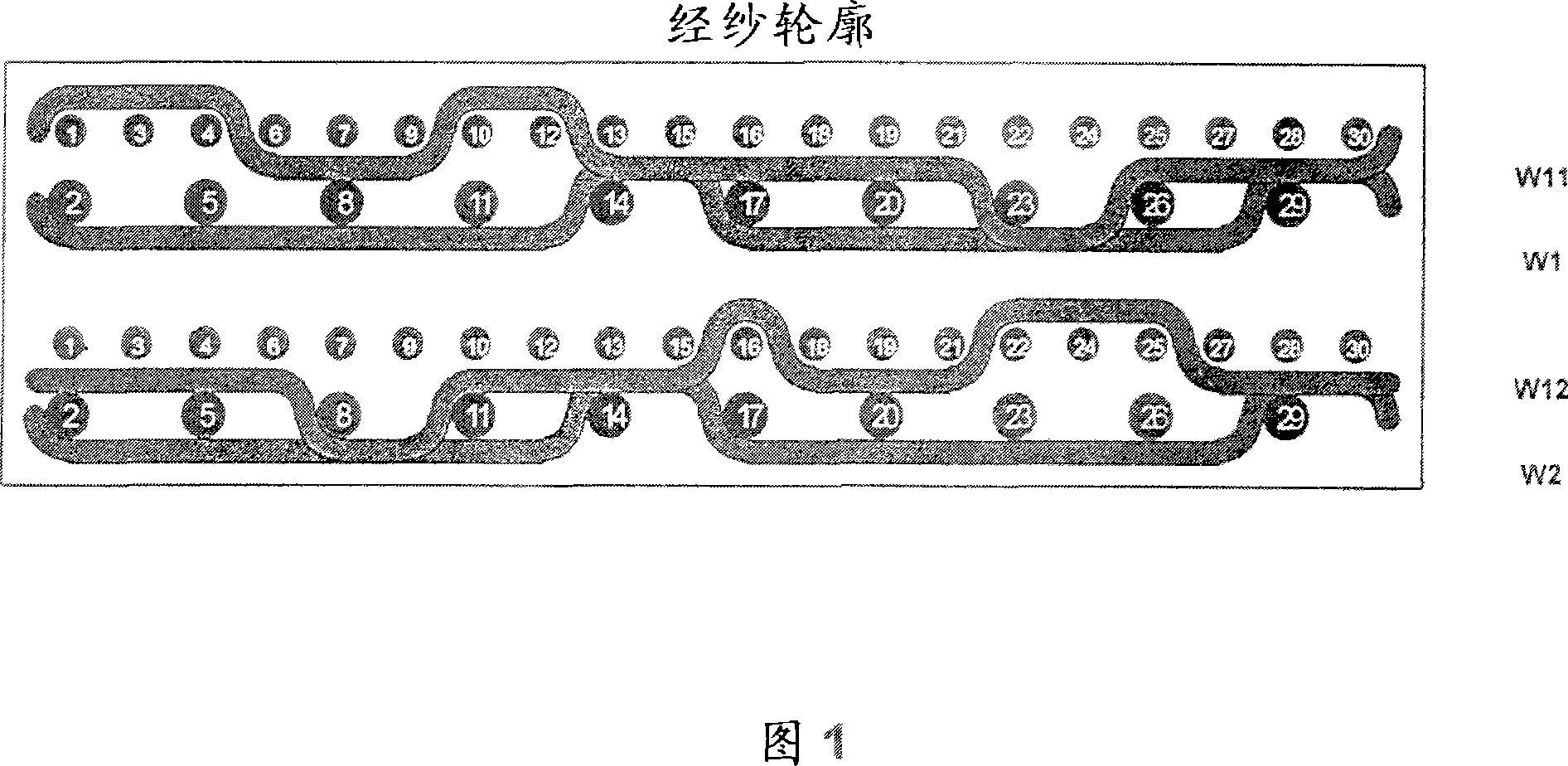

[0023] A preferred embodiment of the present invention describes a three-ply fabric suitable for use in the forming section of a paper machine. The fabric comprises a top or forming layer and a bottom or wear layer. Each layer is composed of interwoven machine direction (MD) yarns or warp yarns and cross-machine direction (CD) yarns or weft yarns. Thus, the fabric consists of forming and fraying weft yarns and forming and fraying warp yarns.

[0024] The forming and wearing layers are held together by forming warp yarns which are interlaced with forming and wearing weft yarns. The forming warp yarns are bonded together in pairs, at least in the forming layer, but also in both layers. Hence, they are called paired intrinsic knots. Here, the term "inner" refers to weaving yarns to provide fiber support to the top layer, rather than simply bonding one layer to another.

[0025] Another feature of the invention is that the warp yarns in the wear layer of the fabric are woven t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com