Dwarf type cover carriage

A technology of uncovering machine and rack, applied in blast furnace parts, furnace, blast furnace details, etc., to achieve the effect of long traverse distance, compact structure, and reduced height and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

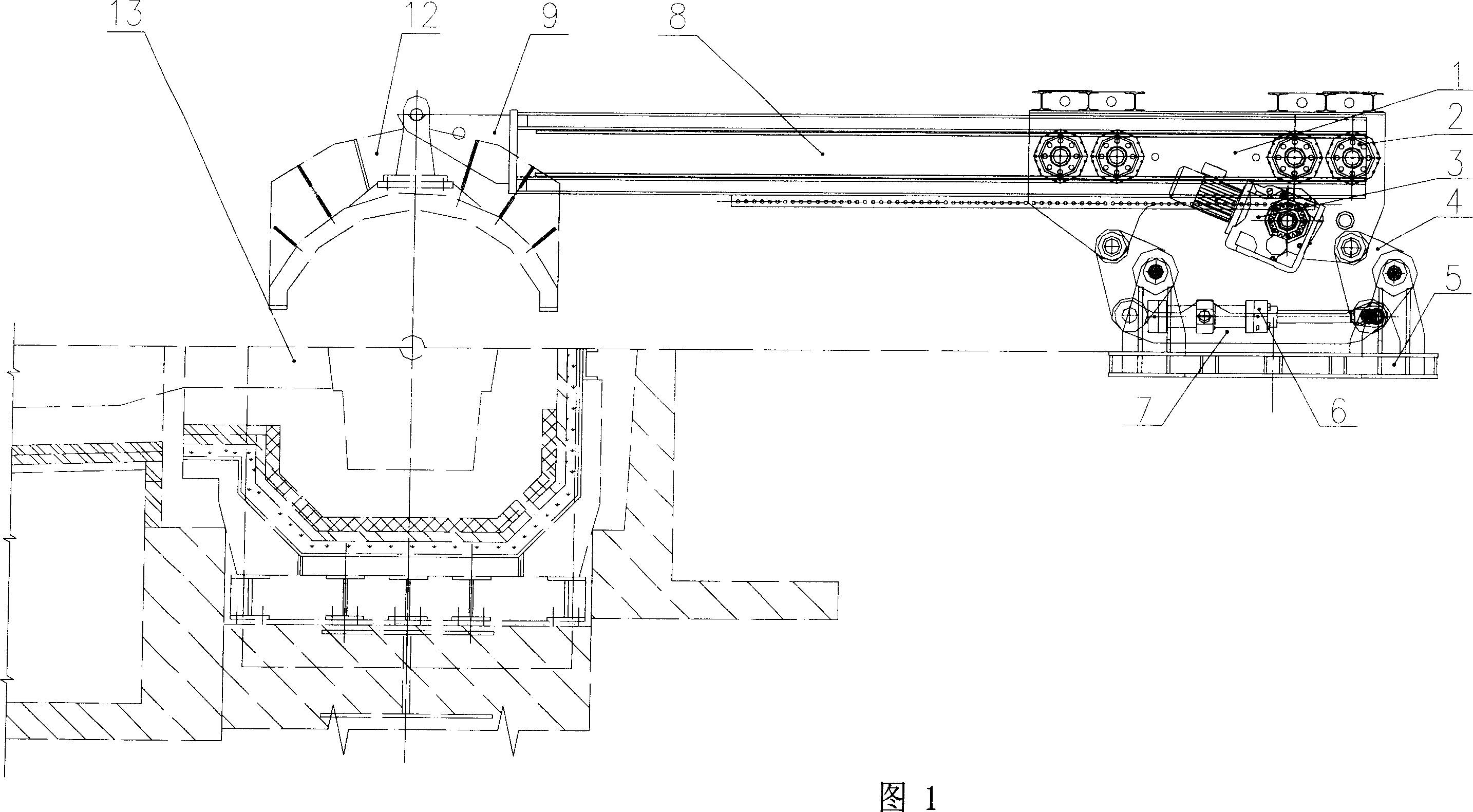

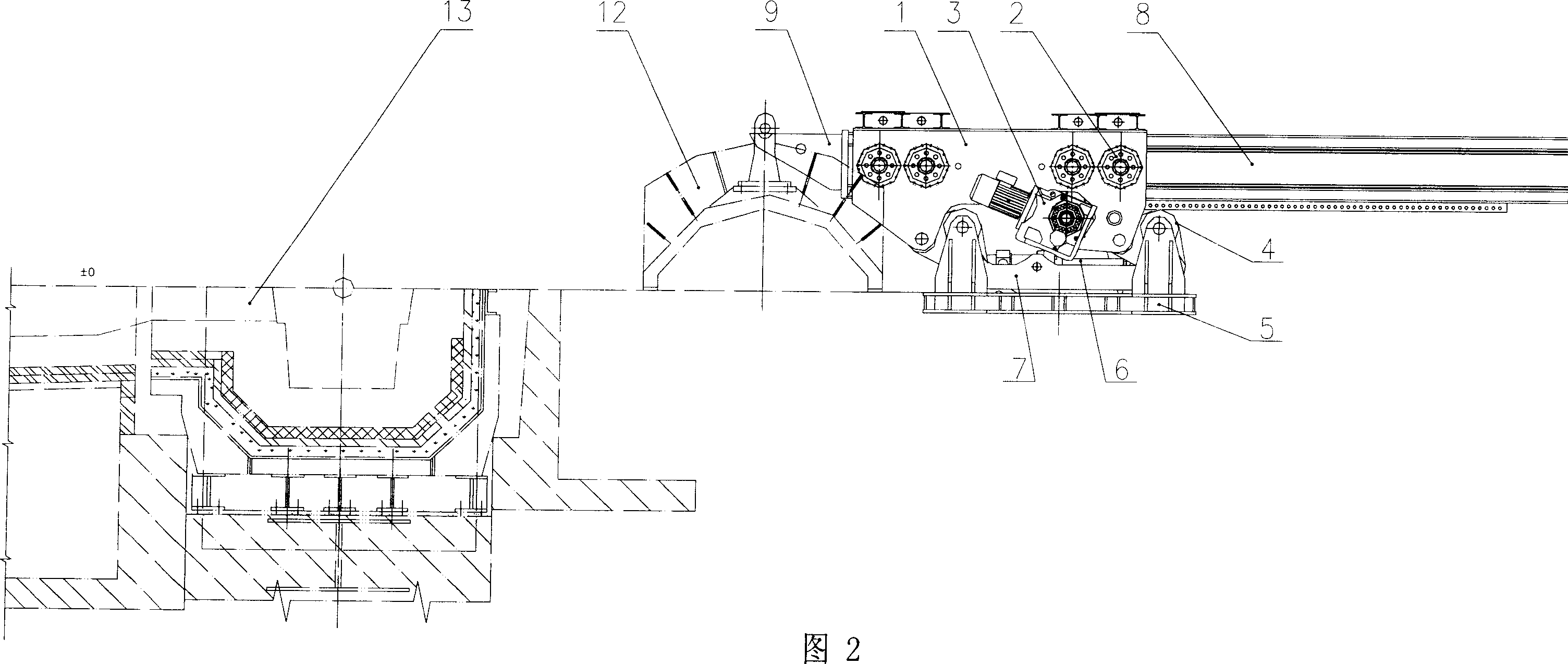

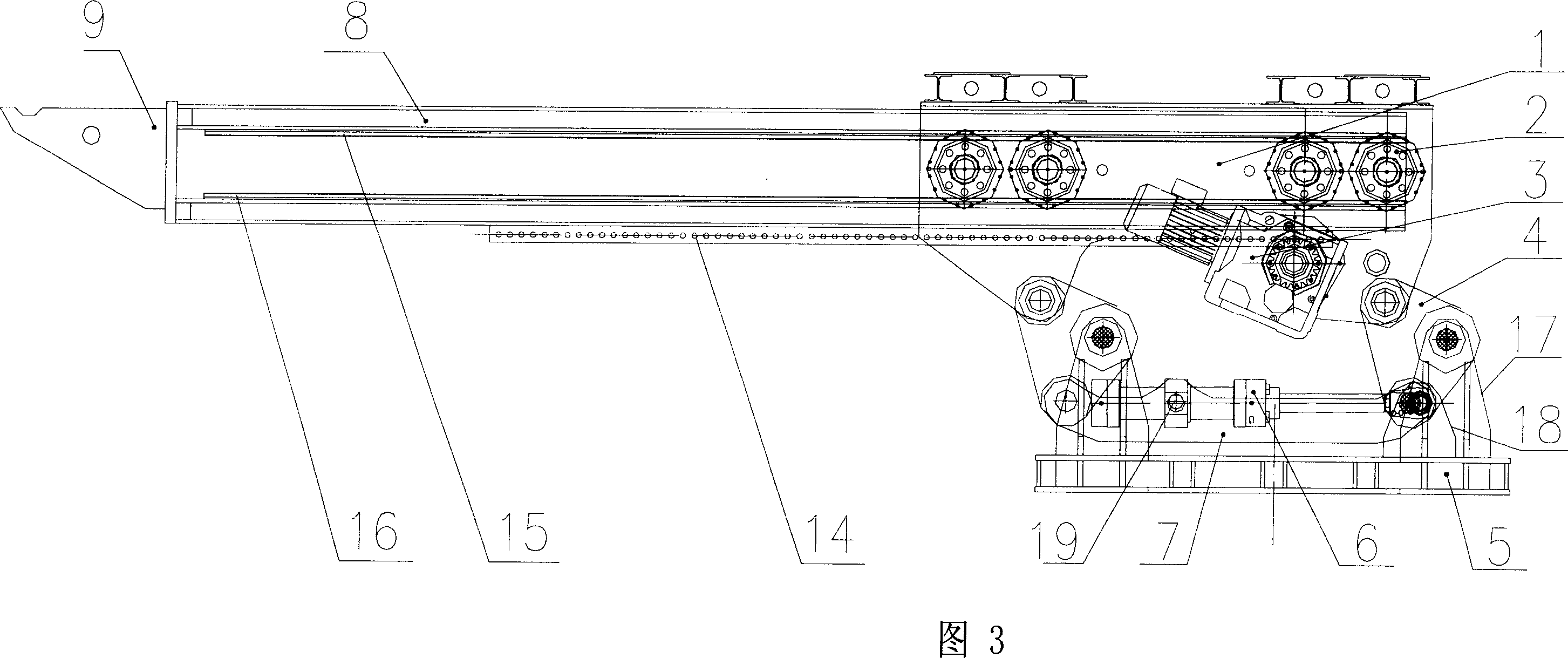

[0022] As shown in Fig. 3, Fig. 4, Fig. 5, Fig. 6, and Fig. 7, the low-type cover removing machine is composed of a lifting device, a frame 1, a horizontal movement mechanism, and a lifting hook 9, and the lifting hook 9 and the horizontal movement mechanism are formed. One end of the moving crossbeam 8 is fixedly connected; the horizontal moving mechanism includes a support wheel 2, a reduction motor 3, a moving crossbeam 8, a gear 10, a transmission shaft 11, a pin rack 14, an upper guide support track 15, a lower guide support track 16, and a moving crossbeam The left and right sides of 8 [the left side in Fig. 4 is the left side, and the right side is the right side] and the upper and lower parts are respectively provided with an upper guide support track 15 and a lower guide support track 16, and the upper guide support track 15 and the upper guide support track 15 on the left and right sides of the mobile crossbeam 8 All be provided with support wheel 2 between lower guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com