Common rail having orifice

A technology of orifice and common rail, applied in the field of common rail, can solve the problems of inability to eliminate the influence of opening timing, difficult, difficult spring constant, etc., and achieve the effect of suppressing the change of injection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

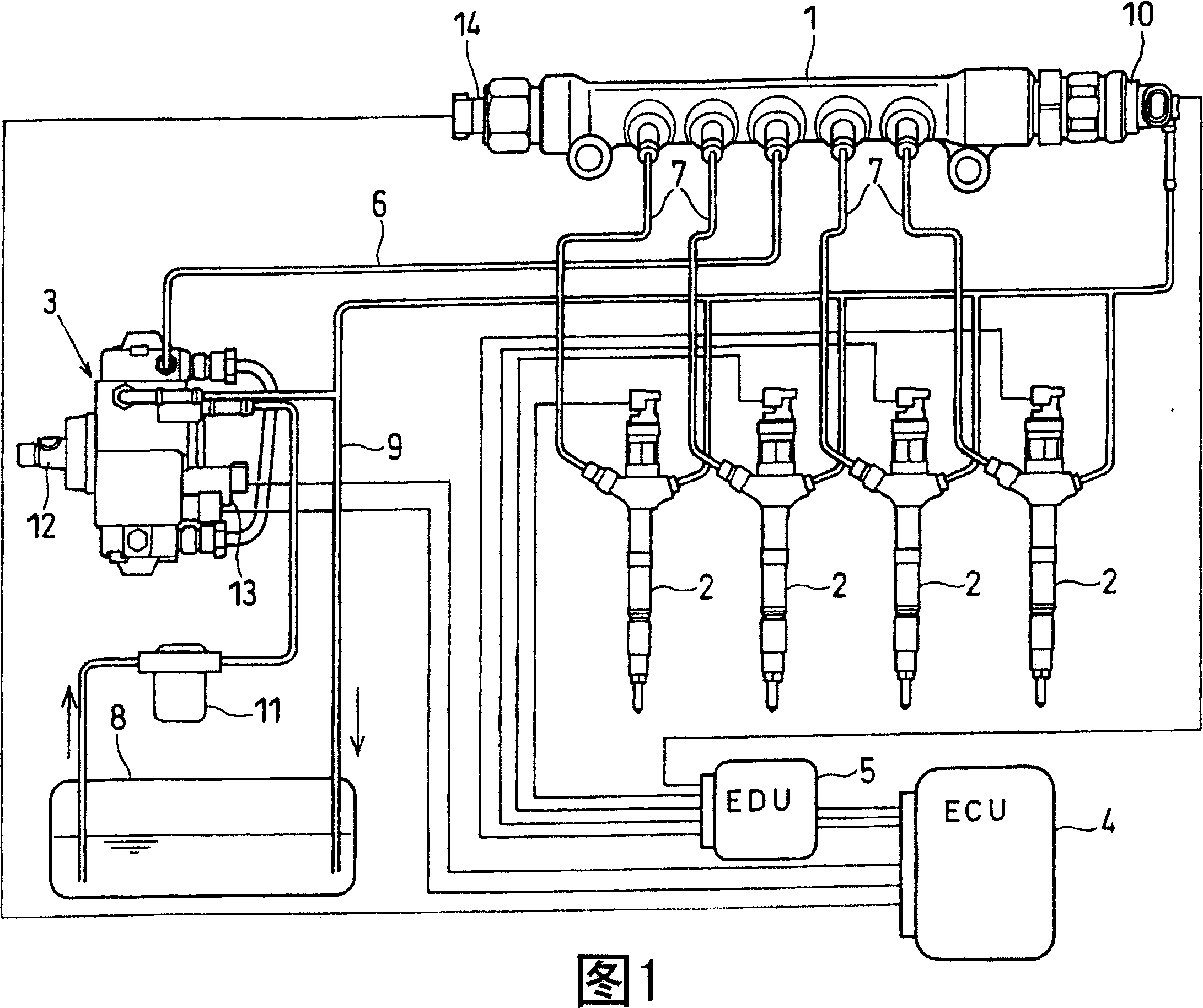

[0052] Referring to FIG. 1, there is shown an accumulator type fuel injection apparatus according to a first exemplary embodiment of the present invention. The fuel injection apparatus shown in FIG. 1 is a system that performs fuel injection to individual cylinders of an engine (such as a diesel engine, not shown). The fuel injection apparatus has a common rail 1, injectors 2, a charge pump 3, an engine control unit (ECU) 4, a drive unit (EDU) 5, and the like. The EDU 5 can be incorporated into the housing of the ECU 4 .

[0053] The common rail 1 is a pressure accumulation container for accumulating high-pressure fuel to be supplied to the injector 2 . In order to accumulate the common rail pressure corresponding to the fuel injection pressure, the common rail 1 is connected to the discharge port of the supply pump 3 through the high pressure pump pipe 6, and the pressure of the supply pump 3 supplies high pressure fuel. The common rail 1 is also connected to a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com