Method and device for mensurating speed of melting protecting slag

A technology of melting speed and mold flux, which is applied in the field of measuring the melting speed of mold flux, can solve the problems of complex structure of the test device, small audience area, large sample size, etc., and achieve strong maintainability of equipment, wide application range, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

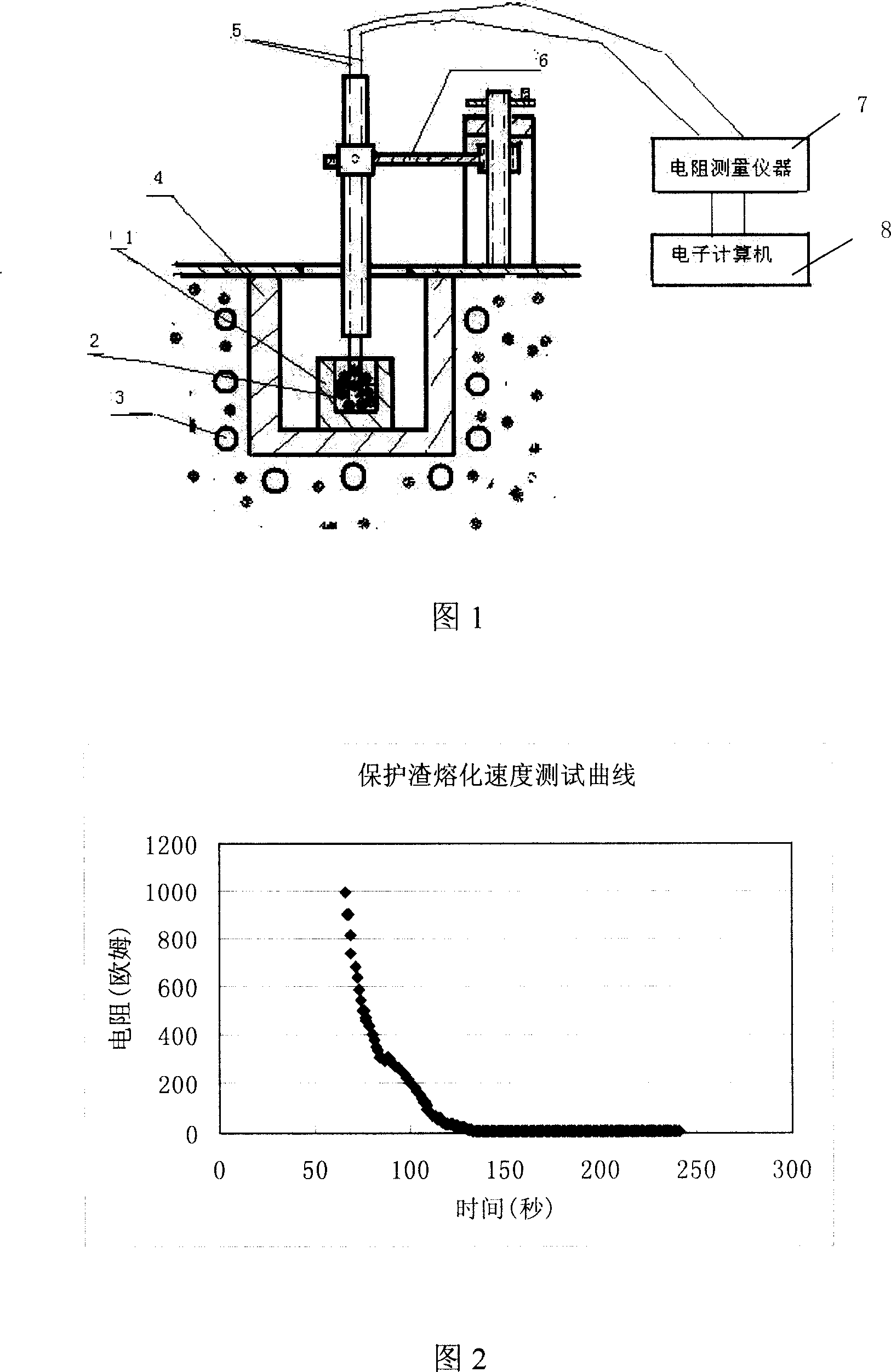

[0032] As shown in Figure 1, it is a schematic structural diagram of a device for measuring the melting rate of mold flux provided by the present invention, which includes a heating device and a measuring device;

[0033] The heating device includes a porcelain boat 1 for loading mold flux samples 2, that is, a crucible and a high-temperature furnace;

[0034] Described porcelain boat 1 is placed in the high-temperature furnace, and it is made of alumina;

[0035] The inner wall of the high-temperature furnace is provided with a hearth brick 4, which is made of high-temperature refractory materials, and the outside of the hearth brick 4 is uniformly provided with a heating element 3, which provides a heat source for the high-temperature furnace and controls the heating and constant temperature operation of the high-temperature furnace;

[0036] The measuring device comprises a metal wire 5 connected in sequence, a resistance measuring instrument 7 and a computer 8;

[0037] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com