LCD base plate with anti static guiding barrier

An anti-static and net-guiding technology, which is applied in the direction of static electricity, electrical components, static indicators, etc., can solve the problems of increasing the steps of control components and increasing manufacturing costs, so as to prevent static protection problems, improve static protection performance, and easy to solve The effect of being hit by static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

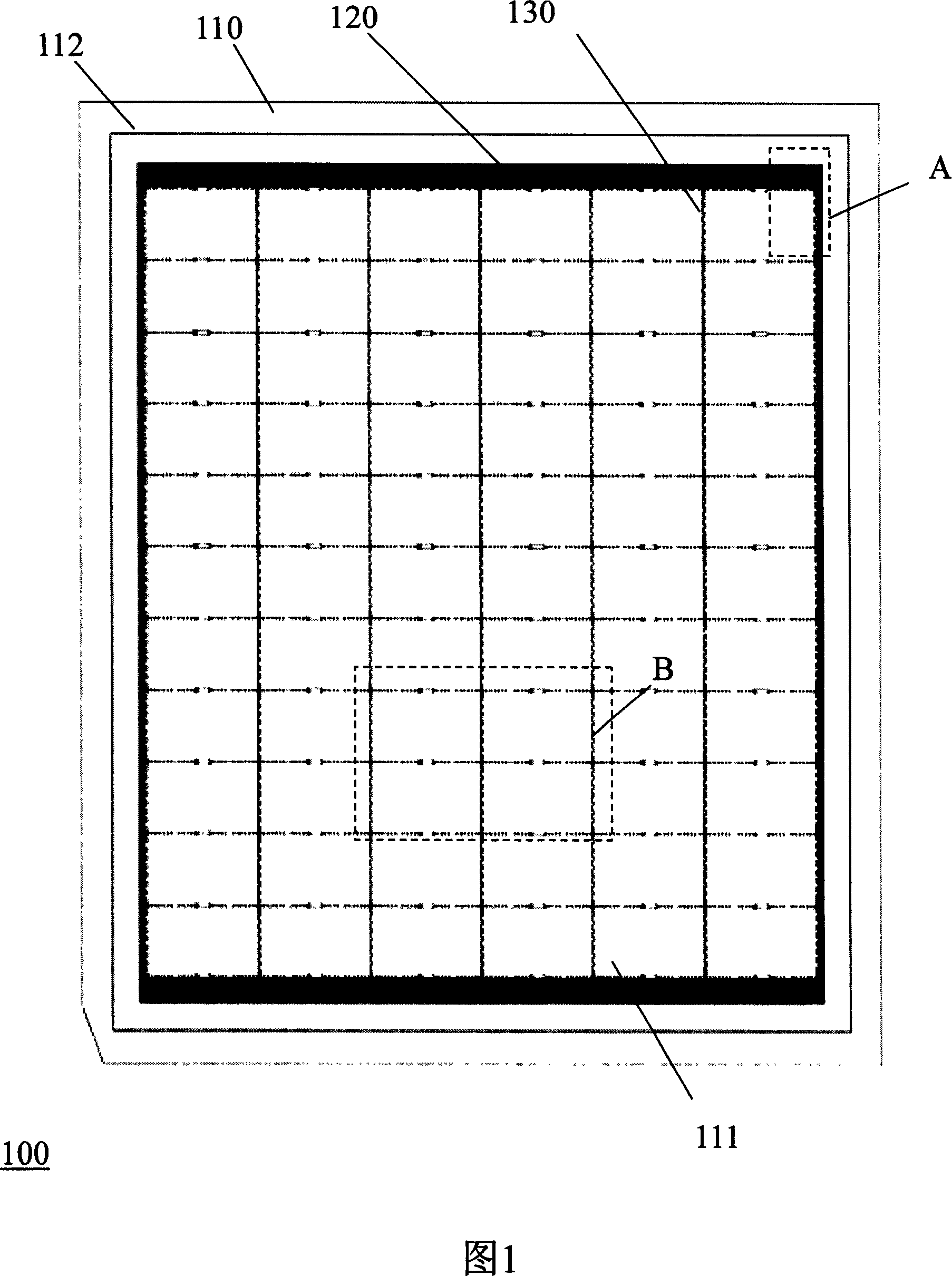

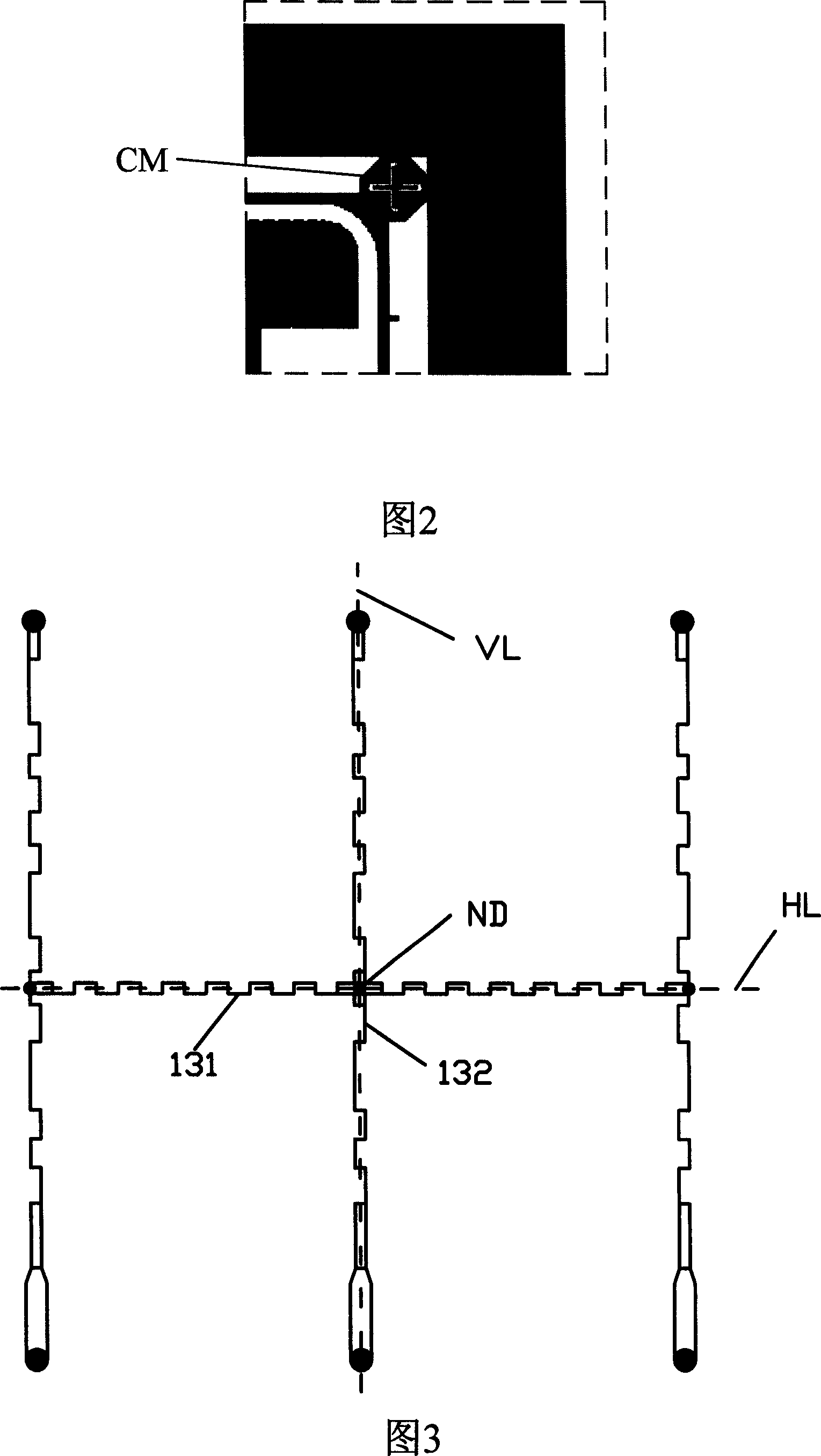

[0020] FIG. 1 is a structural diagram of an LCD substrate with an antistatic guide net according to a specific embodiment of the present invention. Figure 2 and Figure 3 are partial enlarged views. Referring to FIGS. 1 and 3 , an LCD substrate 100 with an antistatic grid includes a substrate 110 , an electrostatic discharge strip 120 , an electrostatic grid 130 , and a plurality of row electrodes and a plurality of column electrodes. Wherein, the substrate 110 has a middle region 111 and a peripheral region 112 , and the peripheral region 112 is adjacent to the middle region 111 . The row electrodes and the column electrodes are disposed in the middle area 111 and are respectively connected to the electrostatic grid 130 .

[0021] In an embodiment of the present invention, the substrate 110 may be made of glass, and the row electrodes and column electrodes may be made of indium tin oxide (ITO), indium zinc oxide (IZO), or other transparent conductive materials. The electrost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com