High anti-penetration concrete mixing material for tunnel shield tube plate and its preparation method

A shield segment and concrete technology, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem that the shield segment cannot meet the engineering requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

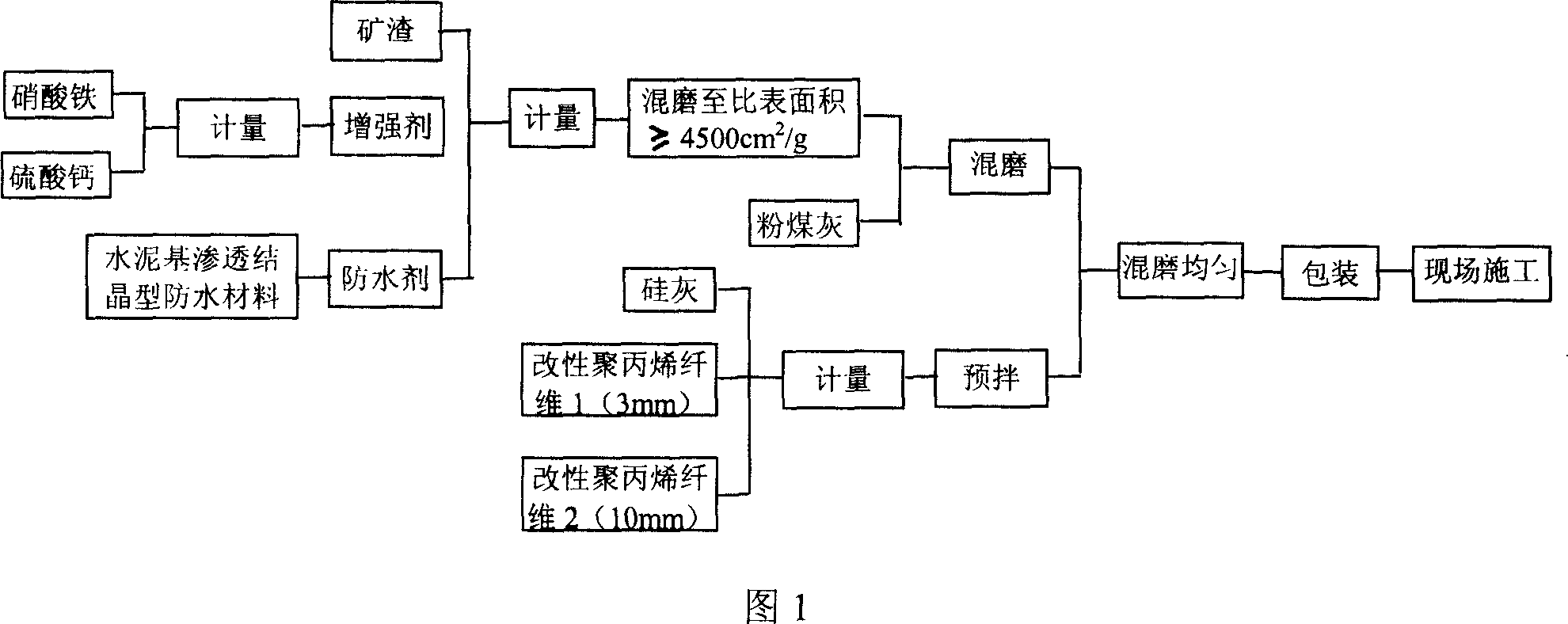

[0024] 1, the preparation method of shield segment high impermeability concrete admixture, it comprises the following steps:

[0025] 1), prepare this admixture by mixing the raw material ratio of table 1:

[0026] Table 1 Mass percentage of each component of the admixture

[0027]

[0028] The mixed fiber is 3mm modified polypropylene fiber and 10mm modified polypropylene fiber compounded at a ratio of 2:1, and the surface of the used polypropylene fiber needs to be modified. Ferric nitrate and calcium sulfate use commercially pure chemicals.

[0029] 2) Add the silica fume and hybrid fibers into the blender in proportion and mix them. The hybrid fibers need to be dispersed manually before adding. The small particles of silica fume are used to disperse the fibers as evenly as possible.

[0030] 3) Mix and grind slag fine powder, ferric nitrate, calcium sulfate, and cement-based permeable crystalline powder in proportion, and then add fly ash to mix until the speci...

Embodiment 3

[0042] Shield segment high impermeability concrete admixture, which is mainly prepared by mixing and grinding slag, fly ash, silica fume and function adjustment component raw materials. The mass percentage of each raw material is: 25% slag, fly ash 47%, silica fume 25%, and functional adjustment component 3%; wherein the functional adjustment component is a reinforcing agent, a waterproofing agent and a toughening agent, and the mass percentage of the reinforcing agent, waterproofing agent, and toughening agent in the functional regulating component is: Strengthening agent 36%, waterproofing agent 51%, toughening agent 13%.

[0043] The reinforcing agent is formed by compounding ferric nitrate and calcium sulfate in a mass ratio of 1:1. The waterproofing agent is a cement-based permeable crystalline waterproofing material (powder). The toughening agent is a hybrid fiber, and the hybrid fiber is compounded by a modified polypropylene fiber of 3mm and a modified polypropylene f...

Embodiment 4

[0049] Shield segment high impermeability concrete admixture, which is mainly prepared by mixing and grinding slag, fly ash, silica fume and function adjustment component raw materials. The mass percentage of each raw material is: slag 40%, fly ash 40%, silica fume 15%, and functional adjustment components 5%; wherein the functional adjustment components are reinforcing agents, waterproofing agents and toughening agents, and the mass percentages of reinforcing agents, waterproofing agents and toughening agents in the functional regulating components are: Strengthening agent 40%, waterproofing agent 48%, toughening agent 12%.

[0050] The reinforcing agent is formed by compounding ferric nitrate and calcium sulfate in a mass ratio of 1:2. The waterproofing agent is a cement-based permeable crystalline waterproofing material (powder). The toughening agent is a hybrid fiber, and the hybrid fiber is compounded by a modified polypropylene fiber of 3mm and a modified polypropylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com