Excellent automatic PCB placing method

A kind of PCB board, excellent technology, applied in the field of excellent PCB automatic board placement, can solve the problems of unable to achieve fixed front and rear distance values, uneven grinding equipment loss, poor equipment grinding uniformity, etc., to improve loss uniformity and improve board placement Efficiency, grinding uniformity and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

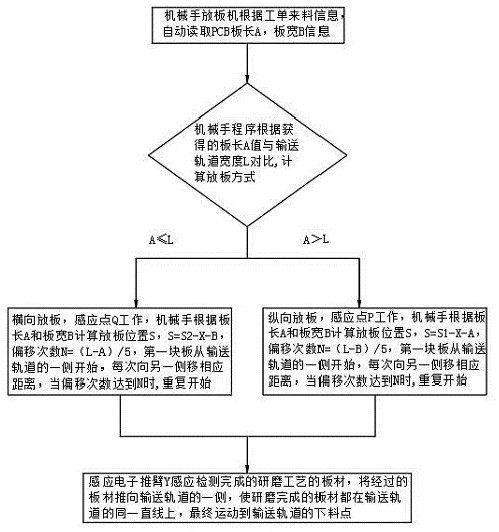

[0032] see Figure 1-2 and image 3 , the present invention provides the following technical solutions: a kind of excellent PCB automatic board placement,

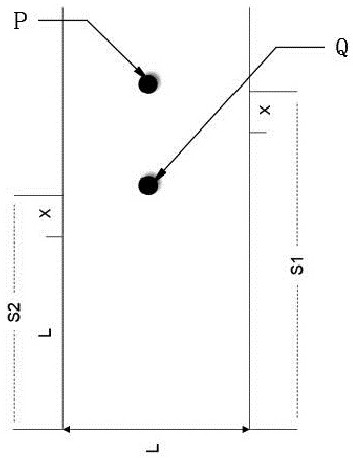

[0033] First set the position S1 of the sensor P, the position of the sensor P: S1=the maximum size of the PCB in the factory +X, when the length of the board is greater than the width of the conveying track, the sensor P works;

[0034] The position of the sensor Q: S2=the width of the horizontal line of the conveying track L+X, when the length of the board is less than the width of the conveying track, the sensor Q will work, increase the sensor Q, and cooperate with the sensor P to conduct induction monitoring on the boards of different specifications to achieve PCBs of any size can be produced at a fixed distance between the front and rear when moving on the horizontal conveyor line, improving the efficiency of board placement;

[0035] Input the information of the board into the manipulator, and the manipulator auto...

Embodiment 2

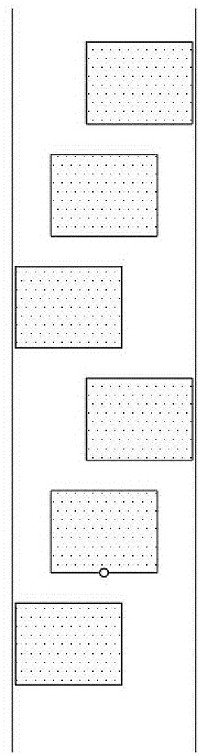

[0045] see Figure 1-2 and Figure 4 , the present invention provides the following technical solutions: a kind of excellent PCB automatic board placement,

[0046] First set the position S1 of the sensor P, the position of the sensor P: S1=the maximum size of the PCB in the factory +X, when the length of the board is greater than the width of the conveying track, the sensor P works;

[0047] The position of the sensor Q: S2=the width of the horizontal line of the conveying track L+X, when the length of the board is less than the width of the conveying track, the sensor Q will work, increase the sensor Q, and cooperate with the sensor P to conduct induction monitoring on the boards of different specifications to achieve PCBs of any size can be produced at a fixed distance between the front and rear when moving on the horizontal conveyor line, improving the efficiency of board placement;

[0048] Input the information of the board into the manipulator, and the manipulator aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com