Cooling pipe for vehicle cooler and production technique thereof

A production process and cooling tube technology, applied in the direction of manufacturing tools, indirect heat exchangers, heat exchanger types, etc., can solve the problems of low production efficiency, affecting product service life, and high matching tolerance requirements by adding spoilers. The effect of reducing solder residue, simplifying production process and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

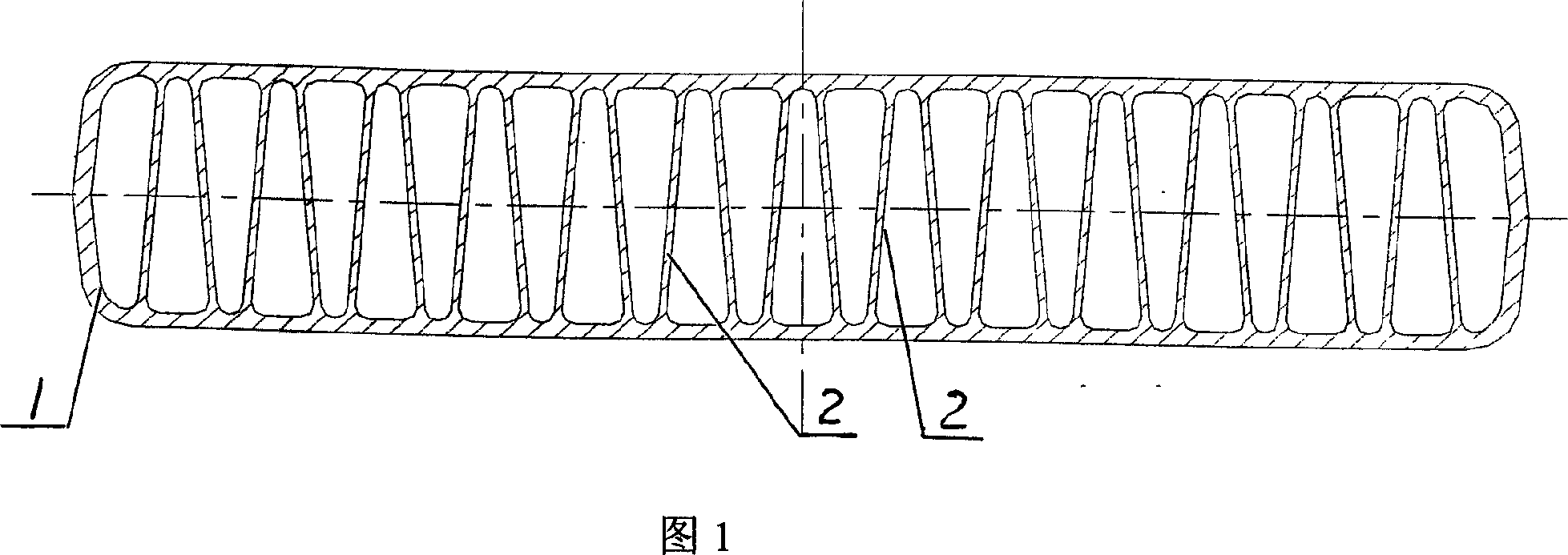

[0009] Embodiment 1: Referring to accompanying drawing 1, the production process step 1 of the cooling pipe for automobile intercooler: cut off the aluminum rod of φ100 to length, and the cutting length is 380 ± 5mm; Step 2: heat the aluminum rod cut to length to 500 -530°C; Step 3: Extrude the heated aluminum rod to length on the aluminum profile extrusion machine to extrude a long profile with a certain cross-sectional size; Step 4: Calibrate the extruded aluminum profile and press Cut off the required length; Step 5: Deburring and cleaning the residue on the inner and outer surfaces.

Embodiment 2

[0010] Embodiment 2: Referring to accompanying drawing 1, the production process of cooling pipes for automobile intercoolers, the product structure is composed of a pipe body 1 and an inclined support partition plate 2, the pipe body 1 has two plane structures up and down, and the left and right ends are circular arcs Structure, the obliquely supported partition plate 2 is connected with the pipe body 1 at an angle of 5-15° and a thickness of 0.2-0.3mm, and the connecting part adopts a circular arc transition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com