Roadway maintenance vehicle with special power source

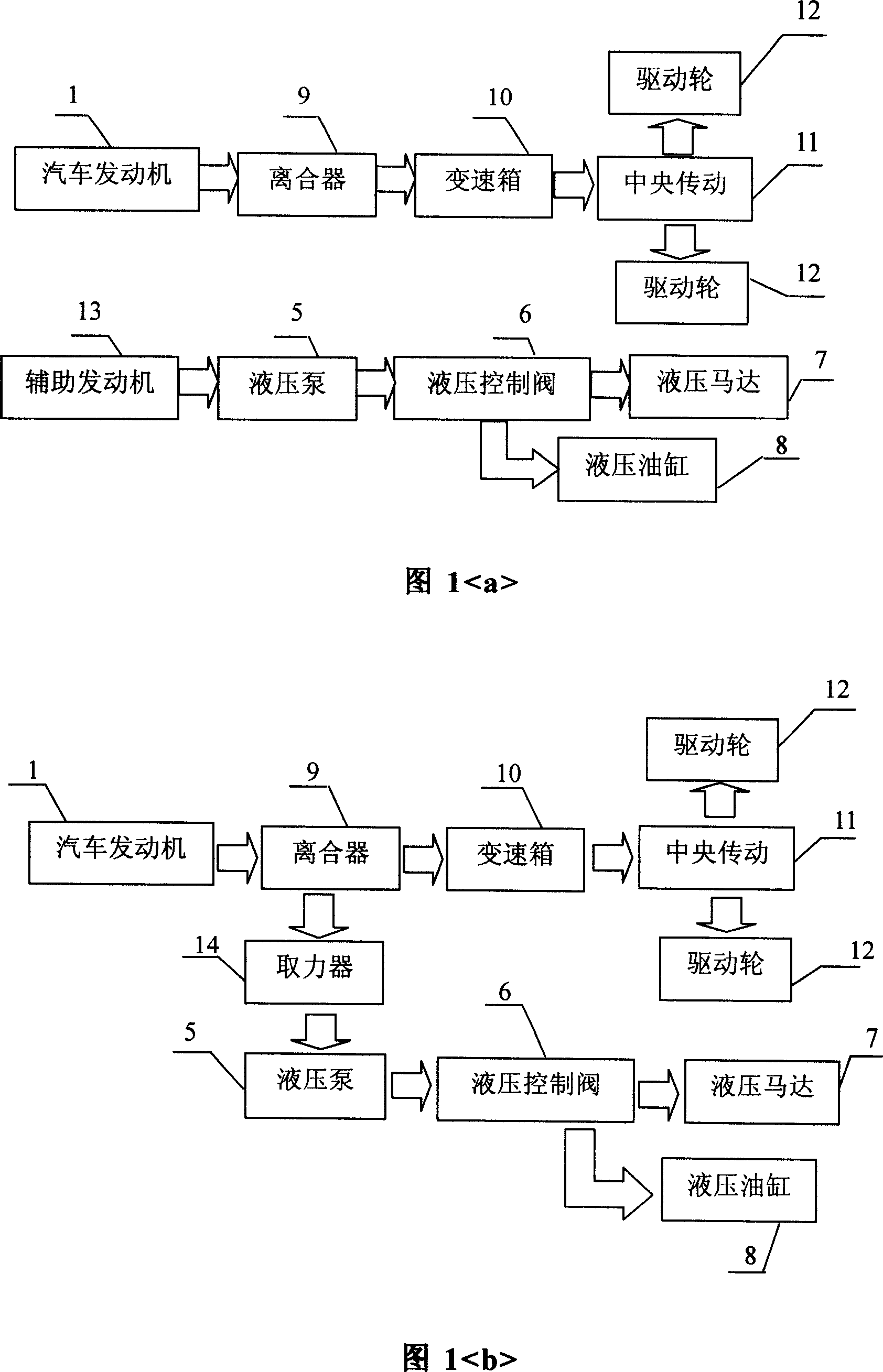

A power and source technology, applied in vehicle parts, roads, roads, etc., can solve the problems of reducing the loading of construction materials, shortening the service life, wasting energy, etc., to increase the available space, prolong the service life, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

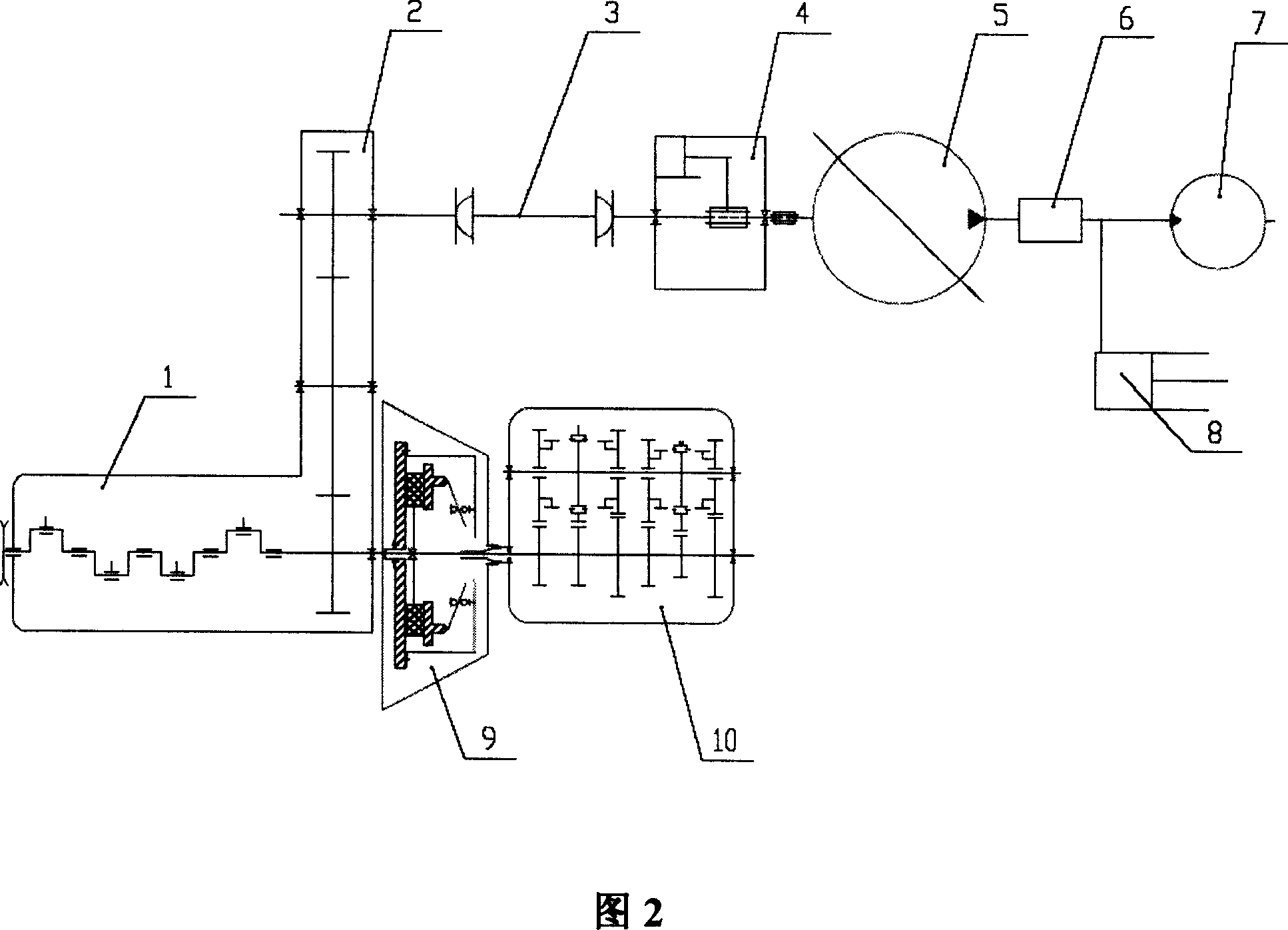

[0009] Describe an embodiment of the present invention below in conjunction with accompanying drawing:

[0010] Fig. 2 is a schematic diagram of the power plant structure of the road surface maintenance vehicle of the present invention, which mainly includes an automobile engine 1, an engine power take-off flange 2, a drive shaft 3, a separator 4, a hydraulic pump 5, a hydraulic control valve 6, a hydraulic motor 7, a hydraulic Oil cylinder 8, clutch 9, gearbox 10.

[0011] On the front end of the engine crankshaft between the automobile engine 1 and the clutch 9, a power take-off flange 2 is fixed; one end of the transmission shaft 3 is connected to the power take-off flange 2 through a universal joint, and the other end is connected to the separator 4; The other end of the separator 4 drives the hydraulic pump 5 to work through the spline shaft.

[0012] In this embodiment, a part of the power output from the automobile engine is transmitted to the clutch 9 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com