Method of preparing aminoglucose composite sulphate

A technology of glucosamine sulfate and glucosamine sulfate, applied in the direction of amino sugar, etc., can solve the problems of high cost, complicated operation, and difficulty in industrialization, and achieve the effect of low cost, simple process, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

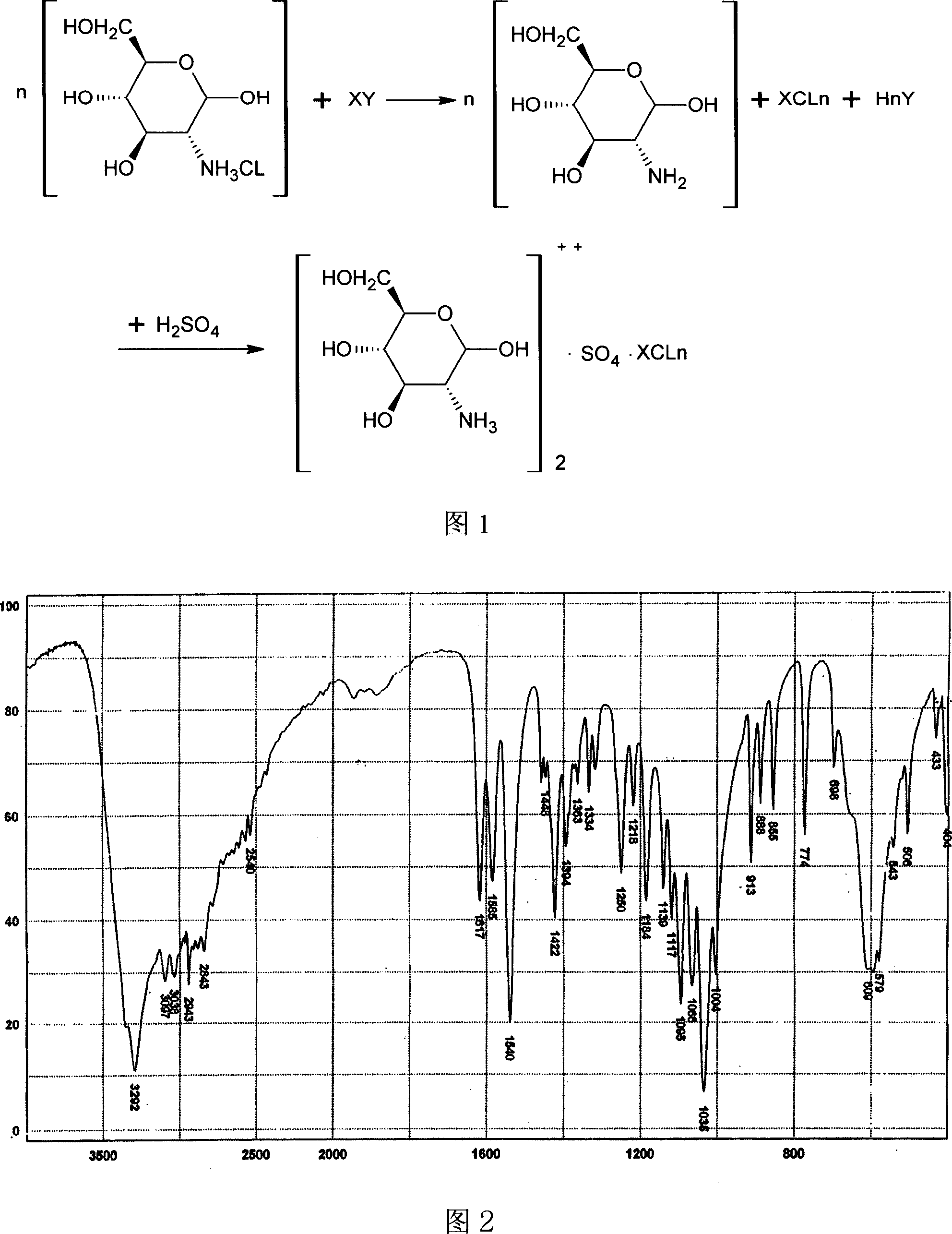

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 22 g of glucosamine hydrochloride was dissolved with 300 ml of water by stirring, and the pH value of the reaction solution was adjusted to 8.0 with NaOH aqueous solution at room temperature. Then the pH value of the reaction solution was adjusted to 4.8 with dilute sulfuric acid and stirred for a while, then concentrated under vacuum until crystals were precipitated, cooled to crystallize, filtered, and dried to obtain 27.8 g of glucosamine sulfate sodium chloride compound salt.

Embodiment 2

[0034] Glucosamine hydrochloride 32g and 400ml 50% ethanol aqueous solution were stirred and dissolved, at room temperature, with NaOCH 2 CH 3 Solution Adjust the pH value of the reaction solution to 8.1. Then the pH value of the reaction solution was adjusted to 4.6 with dilute sulfuric acid and stirred for a while, then concentrated under vacuum until crystals were precipitated, cooled to crystallize, filtered, and dried to obtain 37.5 g of glucosamine sulfate sodium chloride compound salt.

Embodiment 3

[0036] Glucosamine hydrochloride 15g and 200ml water were stirred and dissolved, at room temperature, with Na 2 CO 3 An aqueous solution was used to adjust the pH value of the reaction solution to 8.0. Then the pH value of the reaction solution was adjusted to 4.5 with dilute sulfuric acid and stirred for a while, then concentrated under vacuum until crystals were precipitated, cooled to crystallize, filtered, and dried to obtain 19 g of glucosamine sulfate sodium chloride compound salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com