Super large cross-sectional aluminum alloy beancurd leaf

A technology of aluminum alloy and section, applied in the field of aluminum alloy louvers, can solve the problems of poor rigidity and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

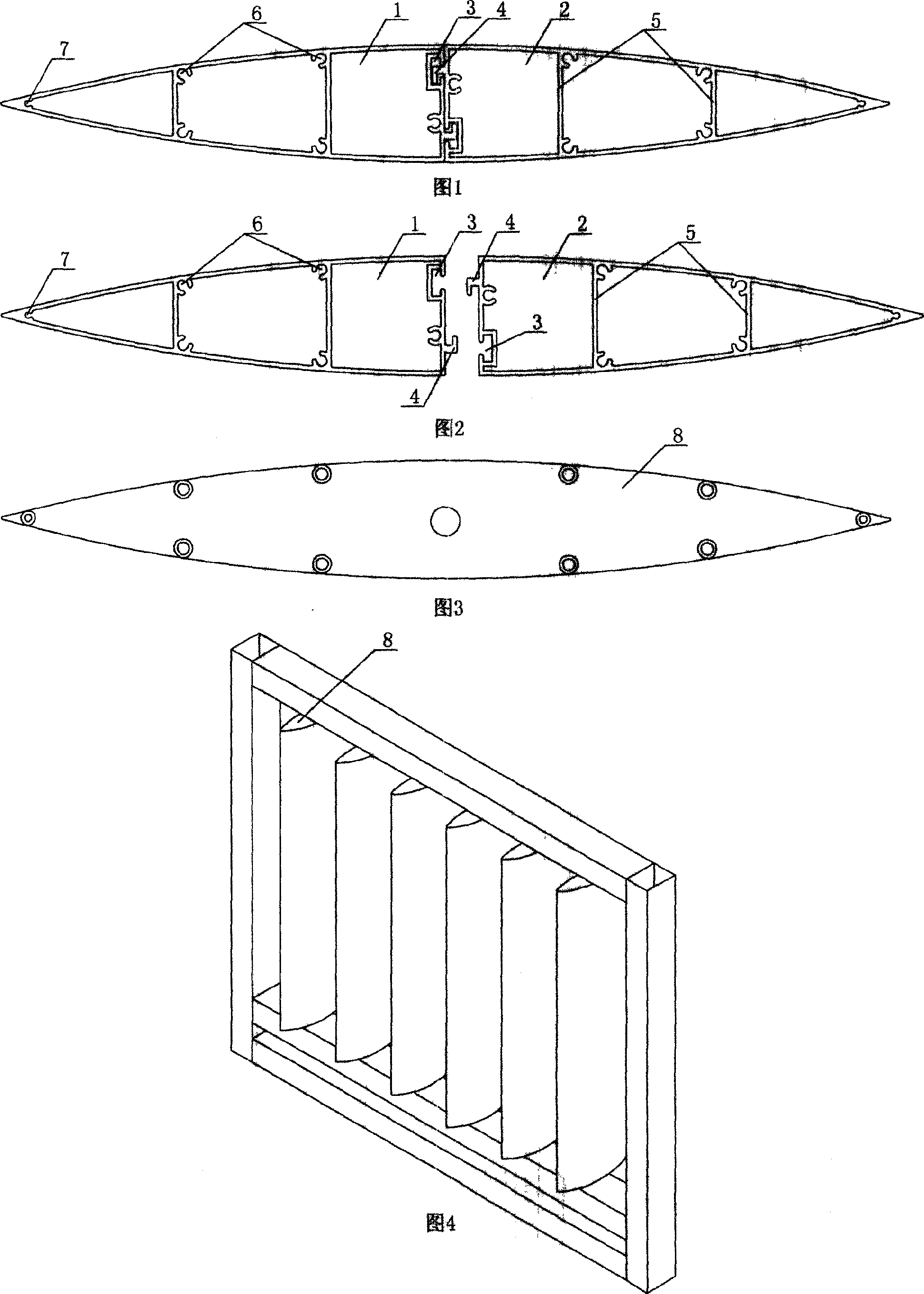

[0013] Set forth the present invention in detail below in conjunction with accompanying drawing:

[0014] As shown in accompanying drawings 1 to 4, the aluminum alloy louvers of this embodiment have a V-shaped cross-section of the left and right half leaves 1 and 2, which is conducive to reducing the interference of wind blowing. The C-shaped card slot 3 and the L-shaped hook bar 4 are assembled by pushing one end of the left half leaf 1 from the other end of the right half leaf 2, so that the C-shaped card slot 3 and the L-shaped hook bar 4 are interlocked. Two reinforcing ribs 5 are respectively formed in the inner cavities of the left and right half leaves 1 and 2, and the two ends of each reinforcing rib are all formed with small cylinders 6 for screwing in by self-tapping screws, and in the left and right half leaves The tails of 1 and 2 are also formed with a small cylinder 7, and the end caps 8 are covered on both sides of the aluminum alloy louvers, and the end caps 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com