Portable well-digging machine

A technology for water supply wells and recharge wells, which is applied to drilling equipment, rotary drilling rigs, drilling equipment and methods, etc., can solve the problems of high construction space requirements, increased comprehensive cost of well completion, and large floor space, avoiding the need for Possibility of dangerous injury, saving total cost of well completion, small occupied area and height space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

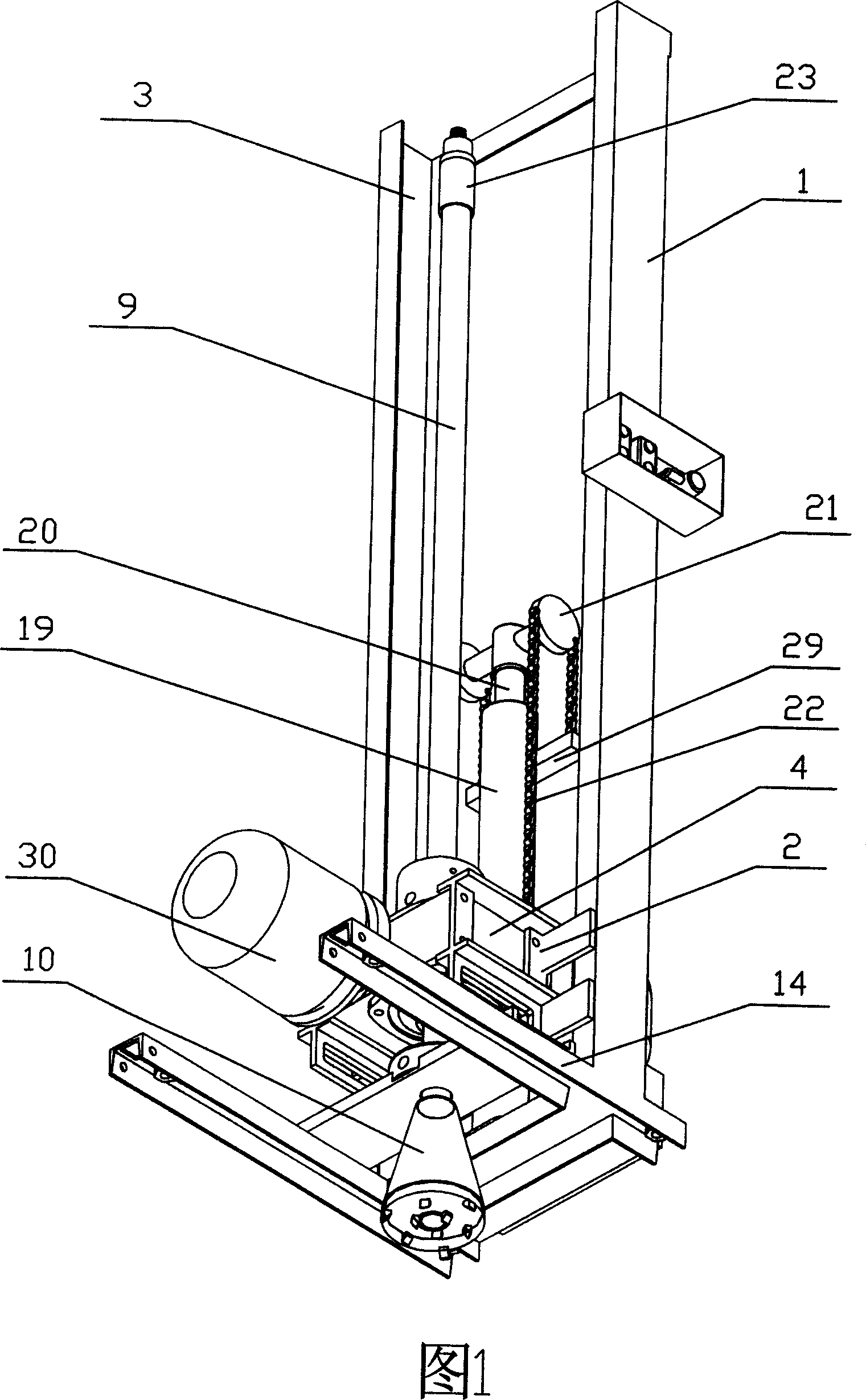

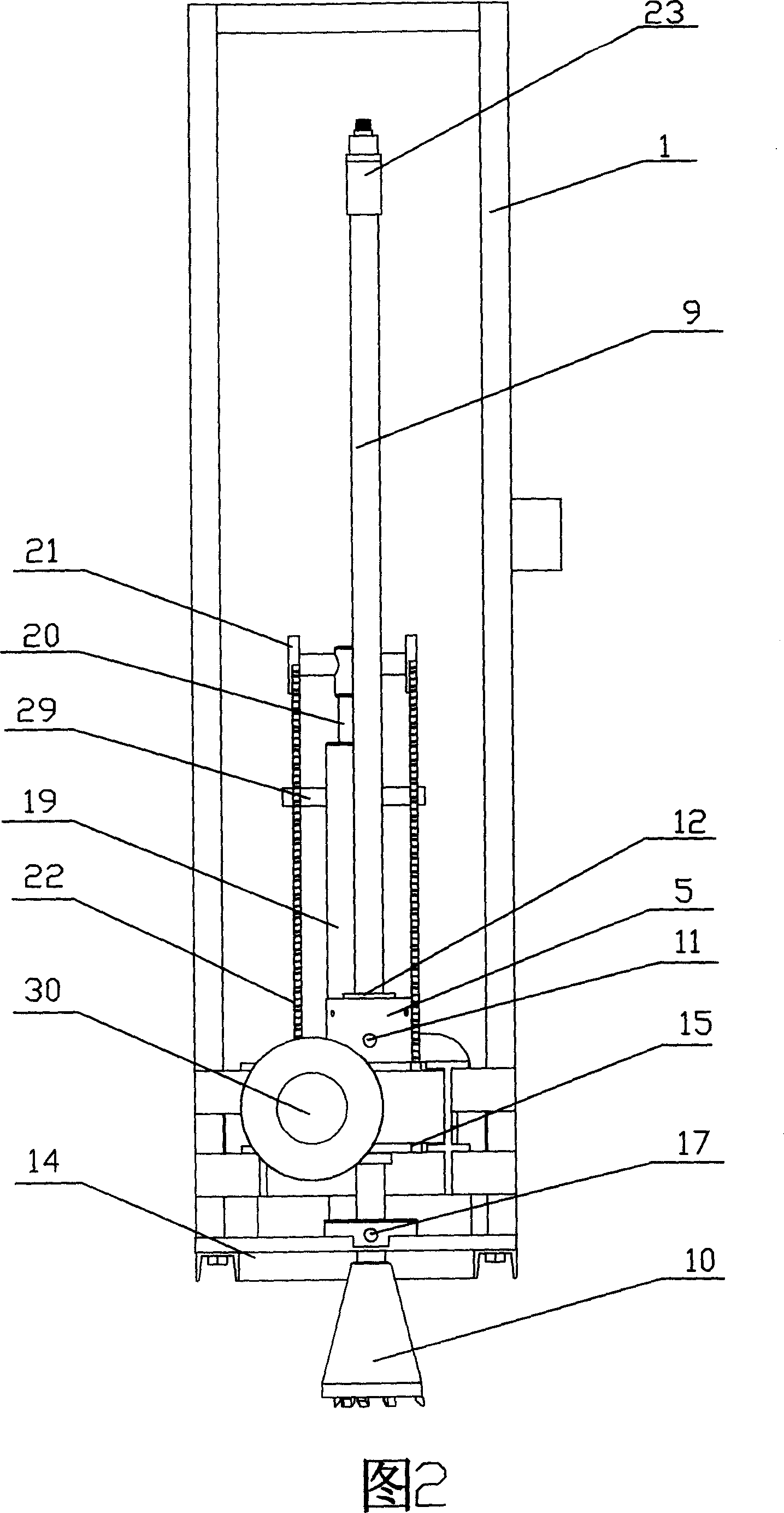

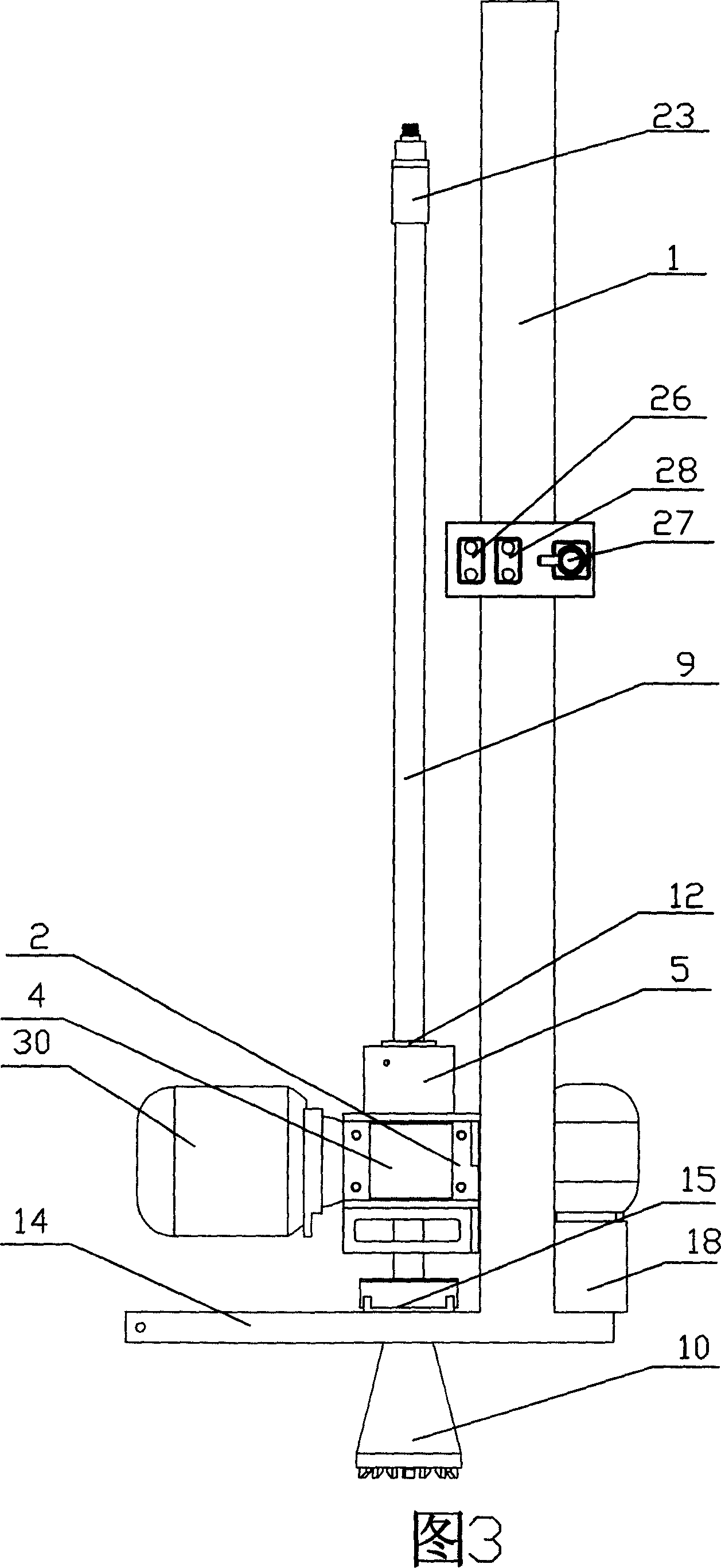

[0027] Embodiment: The portable well drilling machine of this example, as shown in Fig. 1, Fig. 2, Fig. 3, has a vertical frame 1, and the frame 1 is provided with a hydraulic oil pump mechanism 18, and the hydraulic oil pump mechanism 18 is connected with a hydraulic cylinder 19 , the hydraulic cylinder is provided with a hydraulic piston 20, and the hydraulic cylinder is also connected with a chain fixing rod 29. A sprocket 21 is connected to the top of the hydraulic piston 20, and a chain 22 is wound on the sprocket. One end of the chain 22 is connected with the sliding lifting frame 2, and the other end is fixed on the chain fixed rod 29. The sliding lifting frame 2 is provided with a pulley, and the frame 1 is sent with a slide rail 3 in the vertical direction, and the sliding lifting frame 2 is slidably connected in the sliding rail 3 by the pulley.

[0028] The sliding lifting frame 2 is connected with a gearbox 4, and the gearbox 4 is driven by a driving device 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com