Screw compressor rotor

A technology of screw compressors and rotors, applied in mechanical equipment, machines/engines, rotary piston pumps, etc., can solve the problems of reduced axial air tightness, inconvenient processing and testing, and stress concentration, etc., to reduce tooth surface Abrasion, easy processing and detection, and the effect of reducing lateral leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

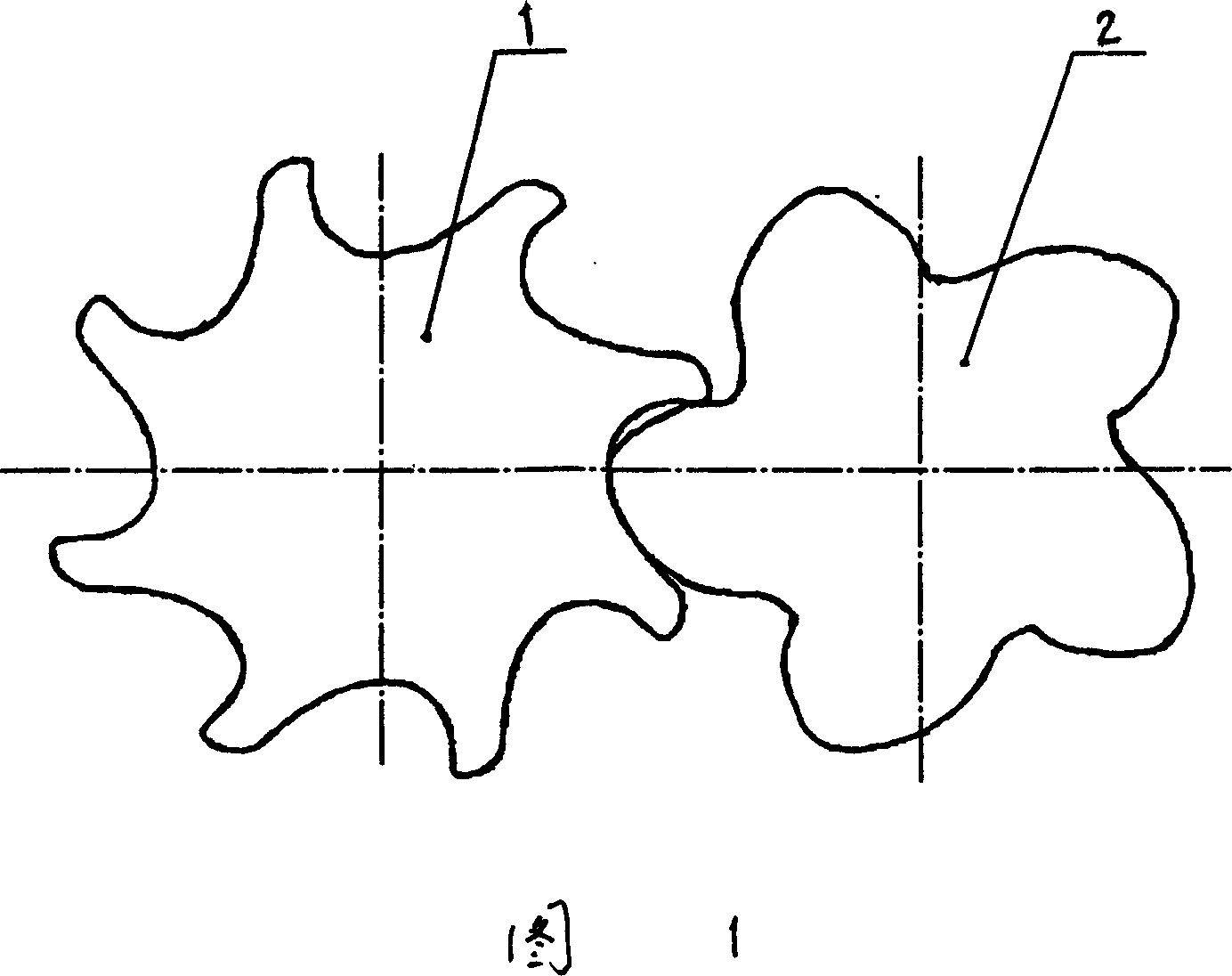

[0012] As shown in FIG. 1 , the present invention includes a female rotor 1 and a male rotor 2 . The two sides of the female rotor 1 and the male rotor 2 are asymmetrical, and the tooth curves are all arcs or arc envelopes. The number of teeth of the female rotor is 8, the number of teeth of the male rotor is 5, and the gap between the male and female rotors is 0.05mm.

[0013] The diameter of the addendum circle of the male rotor is 125mm, and the diameter of the addendum circle of the female rotor is 136mm. The diameter of the dedendum circle of the male rotor is 80mm, and the diameter of the dedendum circle of the female rotor is 91mm. The pitch circle diameter of the male rotor is 83.076mm, and the pitch circle diameter of the female rotor is 132.924mm. The torsion angle of the male rotor is 250°, and the torsion angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com