Permanent magnet system for rotary magnetic refrigeration apparatus

A magnetic refrigeration and magnet technology, which is used in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of high energy consumption, large unilateral magnetic pull, damaged shafts and bearings, etc., and achieves high operational reliability. The effect of low vibration and noise and high magnetizing field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

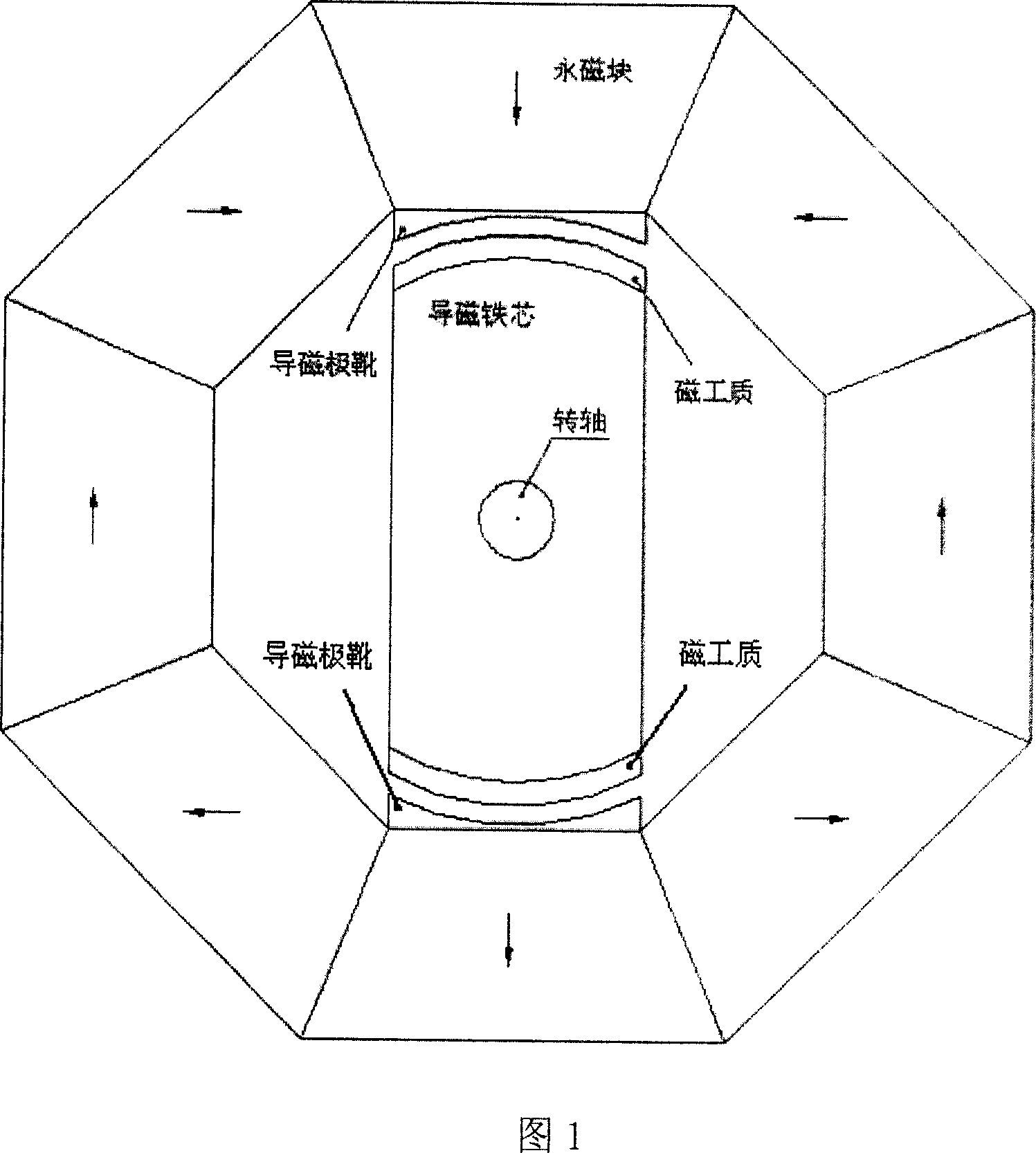

[0018] As shown in Figure 1, the Halbach hollow cylindrical permanent magnet in the stator is composed of 8 trapezoidal permanent magnets, and its magnetization direction is determined by Halbach's rotation theorem, as shown by the arrow in Figure 1. The magnetically conductive pole piece is shaped like an arch bridge, one side of which is consistent with the inner cavity wall of the permanent magnet, and the other side is arc-shaped. The magnetically conductive pole pieces are respectively located under and above the upper and lower permanent magnet blocks magnetized in the radial direction, and are closely attached to the inner cavity walls of the centers of the N and S poles of the permanent magnets. at the geometric center of the stator.

[0019] The axis of the rotor is located at the center of the rotor, and its center coincides with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com