Method for cleaning rubber slag and detritus for circuit board cutting tool

A technology for cutting tools and circuit boards, which is applied in the field of cleaning glue residue and debris, and can solve the problems of burr face wear, affecting the quality of the burr, and reducing the life of the burr, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

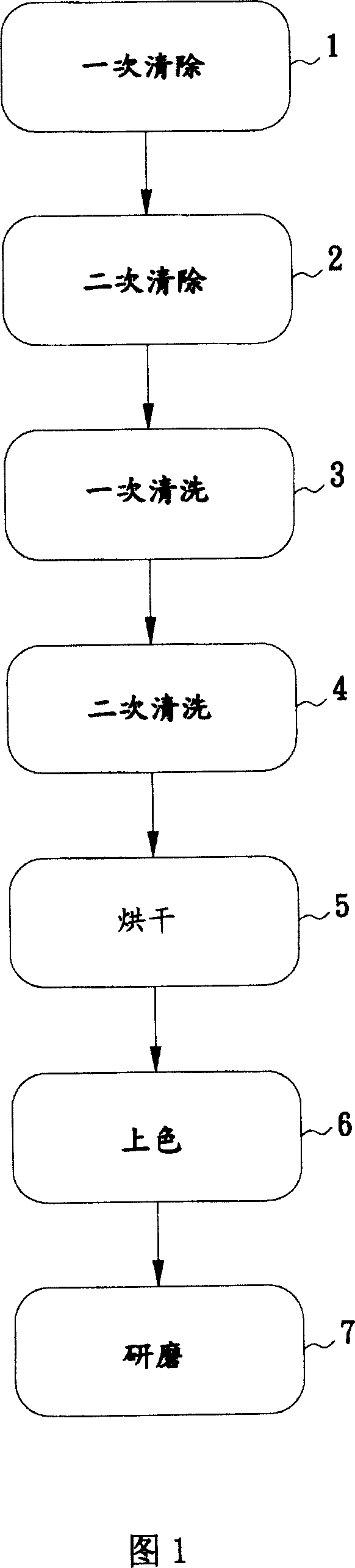

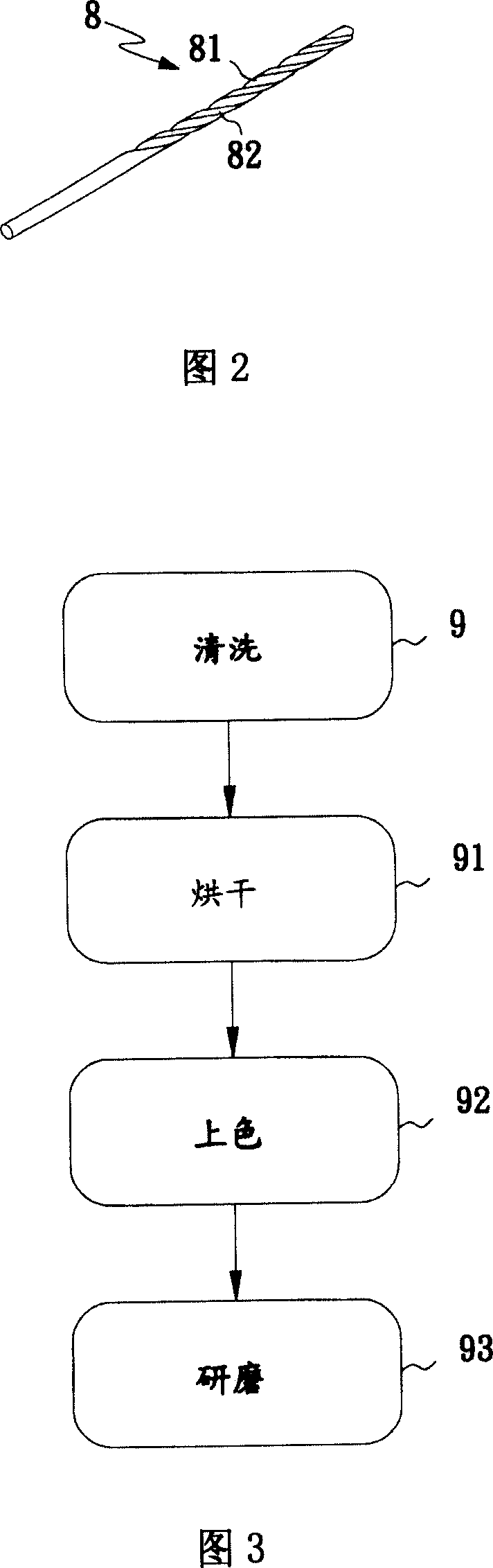

[0028] Please refer to FIG. 1 and FIG. 2 , which are schematic diagrams of the steps of the present invention and schematic diagrams of the three-dimensional appearance of the drill respectively. As shown in the figure: the present invention is a method for cleaning scum residues of circuit board cutting tools, which at least includes primary cleaning 1, secondary cleaning 2, primary cleaning 3, secondary cleaning 4, drying 5, and coloring 6 and grinding 7 and other steps can effectively remove the glue residue on the drill 8, increase the drilling and grinding life of the drill 8, the smoothness of the chip removal groove 81 and the cutting force of the drill 8, and are not easy to break Needle, so as to achieve the effect of improving the quality of the hole wall after drilling.

[0029] And the step of the method for cleaning glue residue residue of circuit board cutting tool of the present invention comprises:

[0030] One-time cleaning 1: Retrieve the used drill 8, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com