Manufacturing method of iron drierfilter

A manufacturing method and filter technology, which are applied in chemical instruments and methods, separation methods, refrigerators, etc., can solve the problems of high production cost of refrigeration equipment, high prices of copper and aluminum, improve smoothness, suppress production costs, The effect of suppressing the increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

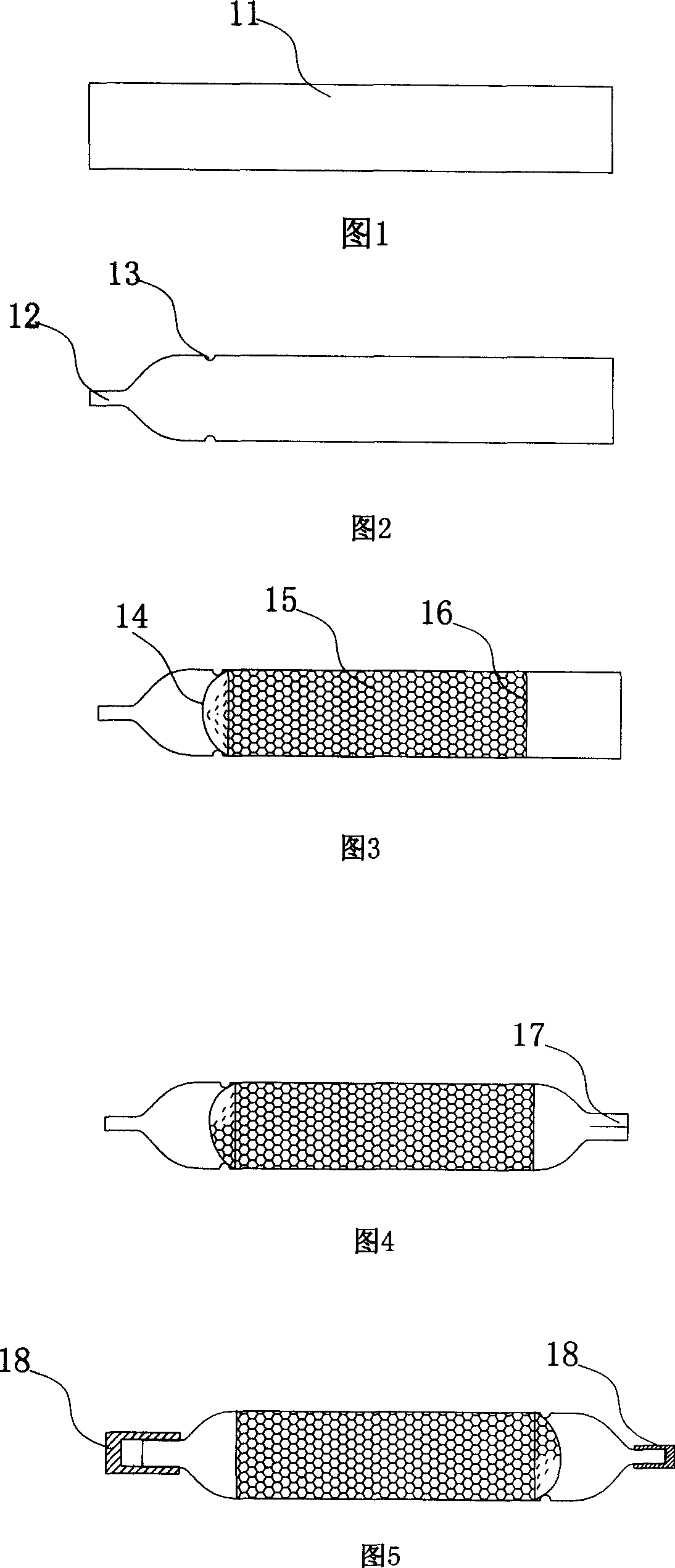

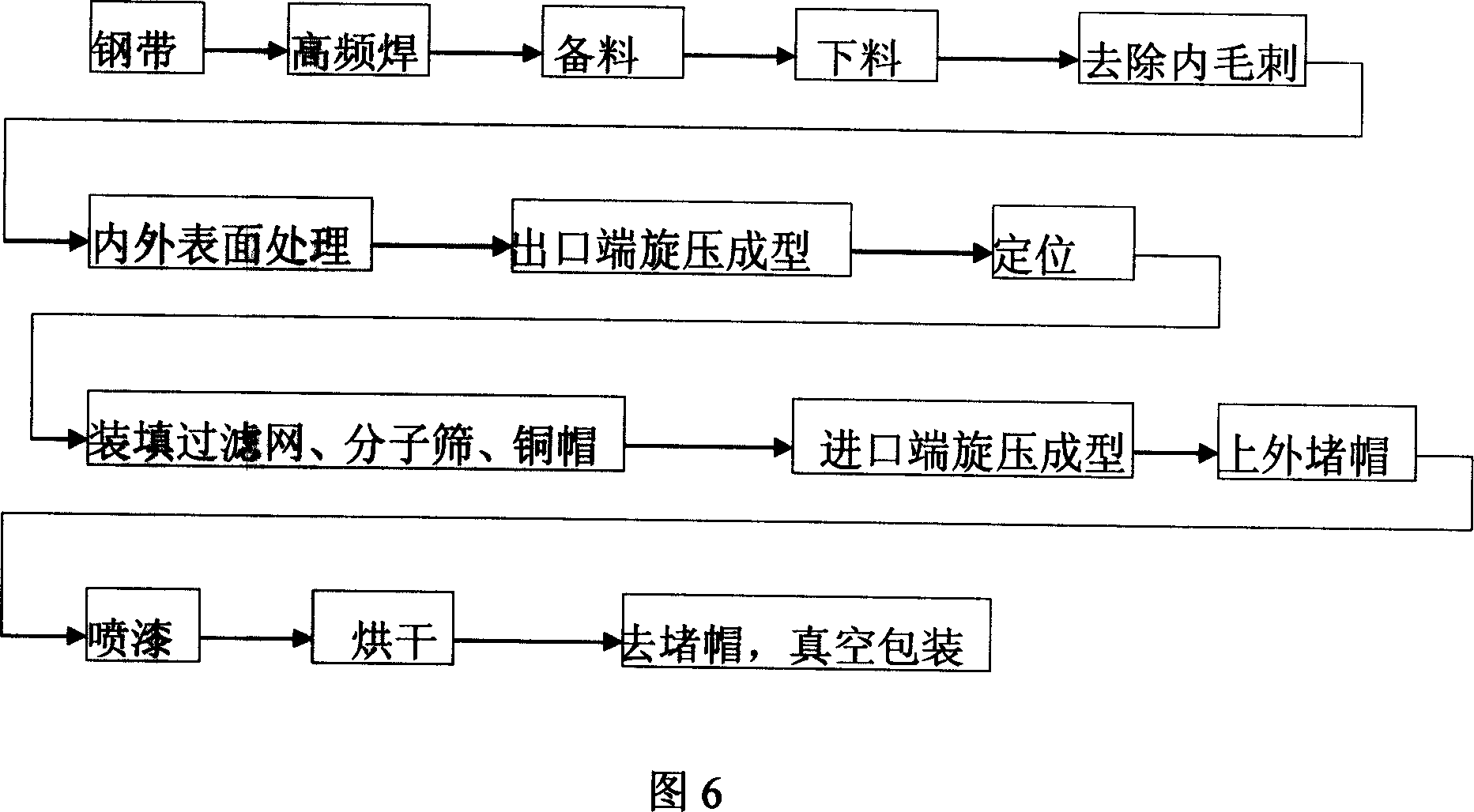

[0039] Embodiment 1: as shown in Figure 6, the concrete steps of the present invention are as follows:

[0040] (1), first select the SPCE cold-rolled steel strip, thickness 0.5mm, C<0.08%, Mn<0.4%, P<0.03%, S<0.03%, Si<0.03%, the width is the same as the circumference of the dry filter cylinder Steel strips of equal length are welded by high frequency into steel pipes;

[0041] As shown in Figure 1:

[0042] (2), then the steel pipe manufactured in step (1) is cut to length according to the model of the dry filter, and the burrs are removed at the cut steel pipe two ends;

[0043] (3), then step (2) handles blank 11 and does inner and outer surface treatment:

[0044] a. Put the billet into the alkali tank for 20 minutes at a temperature of 80°C,

[0045] b. Shake and wash in tap water for 20 seconds,

[0046] c. Put the billet into the acid tank and shake it six times, and leave it for 60 minutes.

[0047] d. Then shake and wash in the tap water tank for 20 seconds,

...

Embodiment 2

[0065] Embodiment 2: as shown in Figure 6, the concrete steps of the present invention are as follows:

[0066] (1), first select the SPCE cold-rolled steel strip, thickness 0.5mm, C<0.08%, Mn<0.4%, P<0.03%, S<0.03%, Si<0.03%, the width is the same as the circumference of the dry filter cylinder Steel strips of equal length are welded by high frequency into steel pipes;

[0067] As shown in Figure 1:

[0068](2), then the steel pipe manufactured in step (1) is cut to length according to the model of the dry filter, and the burrs are removed at the cut steel pipe two ends;

[0069] (3), then step (2) handles blank 11 and does inner and outer surface treatment:

[0070] a. Put the billet into the alkali tank for 40 minutes at a temperature of 70°C,

[0071] b. Shake and wash in tap water for 10 seconds,

[0072] c. Put the billet into the acid tank and shake it six times, and leave it for 40 minutes.

[0073] d. Then shake and wash in the tap water for 10 seconds,

[0074]...

Embodiment 3

[0091] Embodiment 3: as shown in Figure 6, the concrete steps of the present invention are as follows:

[0092] (1), first select the SPCE cold-rolled steel strip, thickness 0.5mm, C<0.08%, Mn<0.4%, P<0.03%, S<0.03%, Si<0.03%, the width is the same as the circumference of the dry filter cylinder Steel strips of equal length are welded by high frequency into steel pipes;

[0093] As shown in Figure 1:

[0094] (2), then the steel pipe manufactured in step (1) is cut to length according to the model of the dry filter, and the burrs are removed at the cut steel pipe two ends;

[0095] (3), then step (2) handles blank 11 and does inner and outer surface treatment:

[0096] a. Put the billet into the alkali tank for 60 minutes at a temperature of 90°C,

[0097] b. Shake and wash in tap water for 80 seconds,

[0098] c. Put the billet into the acid tank and shake it six times, and leave it for 80 minutes.

[0099] d. Then shake and wash in the tap water for 10 seconds,

[0100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com