Multifunctional micro friction wear testing machine

A wear test and micro-friction technology, applied in the field of testing machines, can solve problems such as the inability to test the form of twisting motion, and achieve the effects of small errors, reasonable layout and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

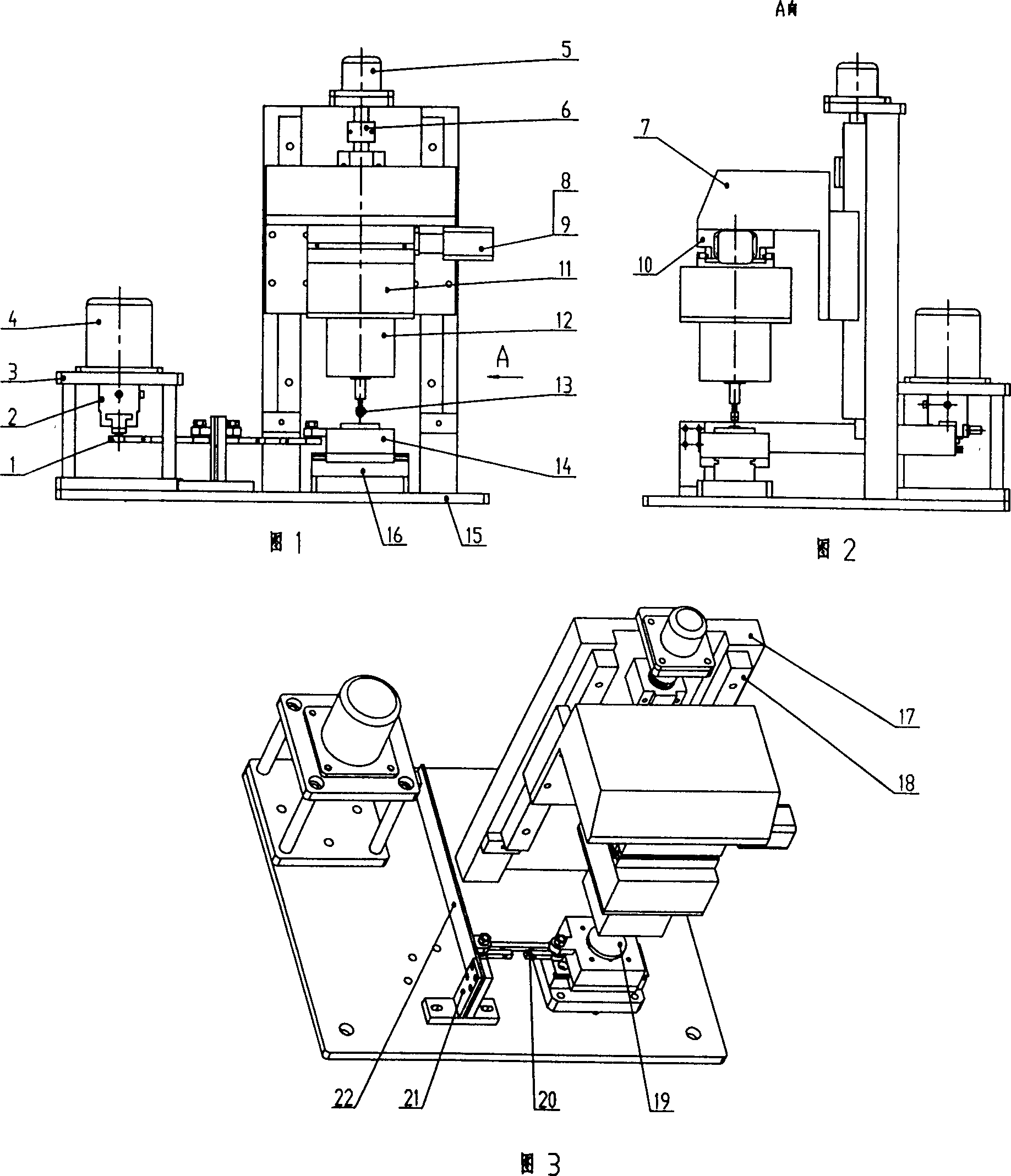

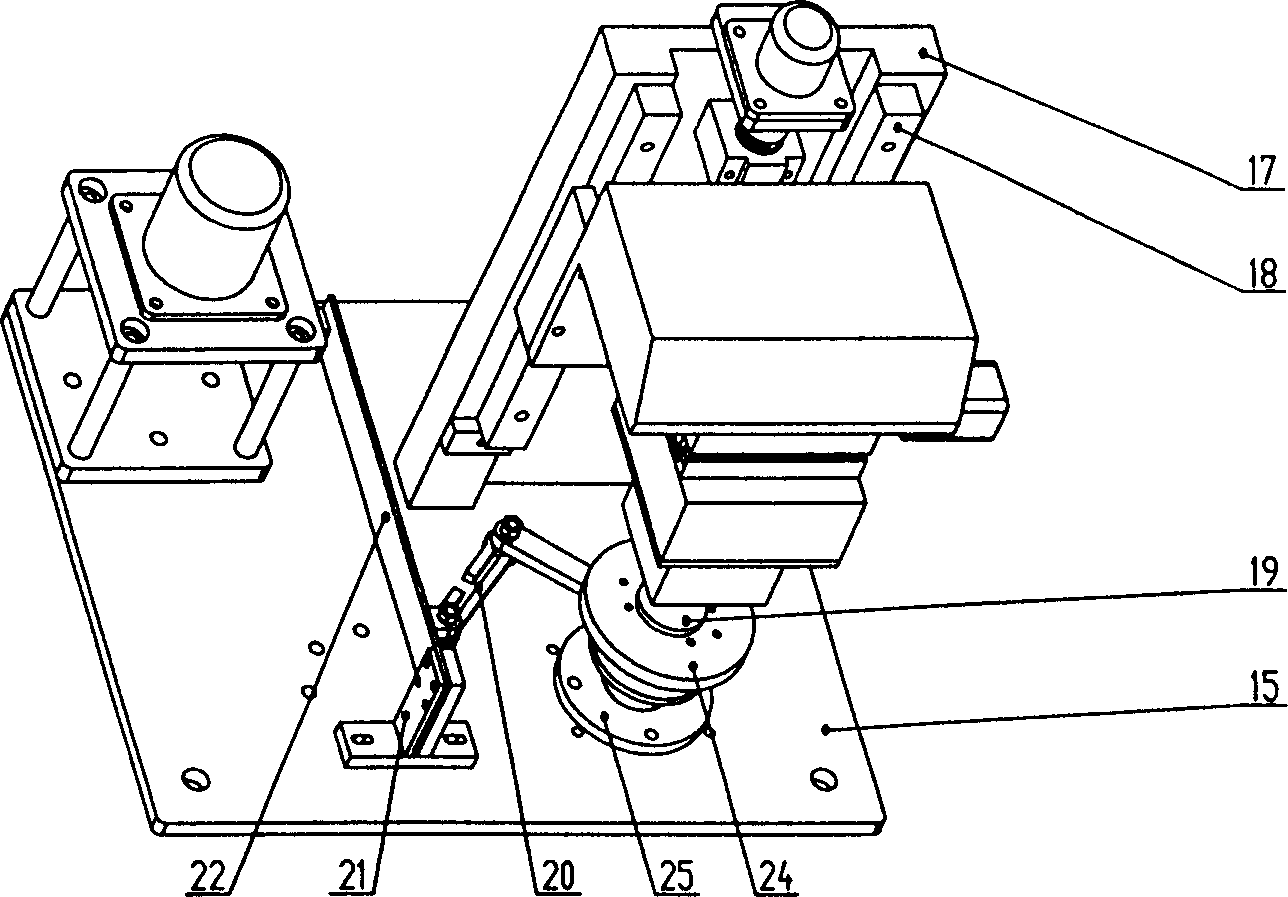

[0022] Embodiment one: figure 1 figure 2 image 3 As shown, the micro-friction and wear testing machine is composed of a driving device, a moving device, a loading and measuring device, and a lifting platform arranged on the base plate 15. The driving device is connected to the The moving devices are hinged together, and according to the proportional amplification and elastic bending of the cantilever elastic plate 22, a small vibration amplitude is generated at the hinge joint between the cantilever elastic plate 22 and the connecting rod 20, and the small vibration amplitude is transmitted to the sliding table (or rotating table) through the connecting rod . The loading and measuring device is connected with the lifting platform and is located above the moving device. The driving device is composed of a motor bracket 3, a stepping motor 4 and an eccentric body 2, the stepping motor 4 is arranged on the motor bracket 3, the eccentric body 2 is connected to the transmissio...

Embodiment 2

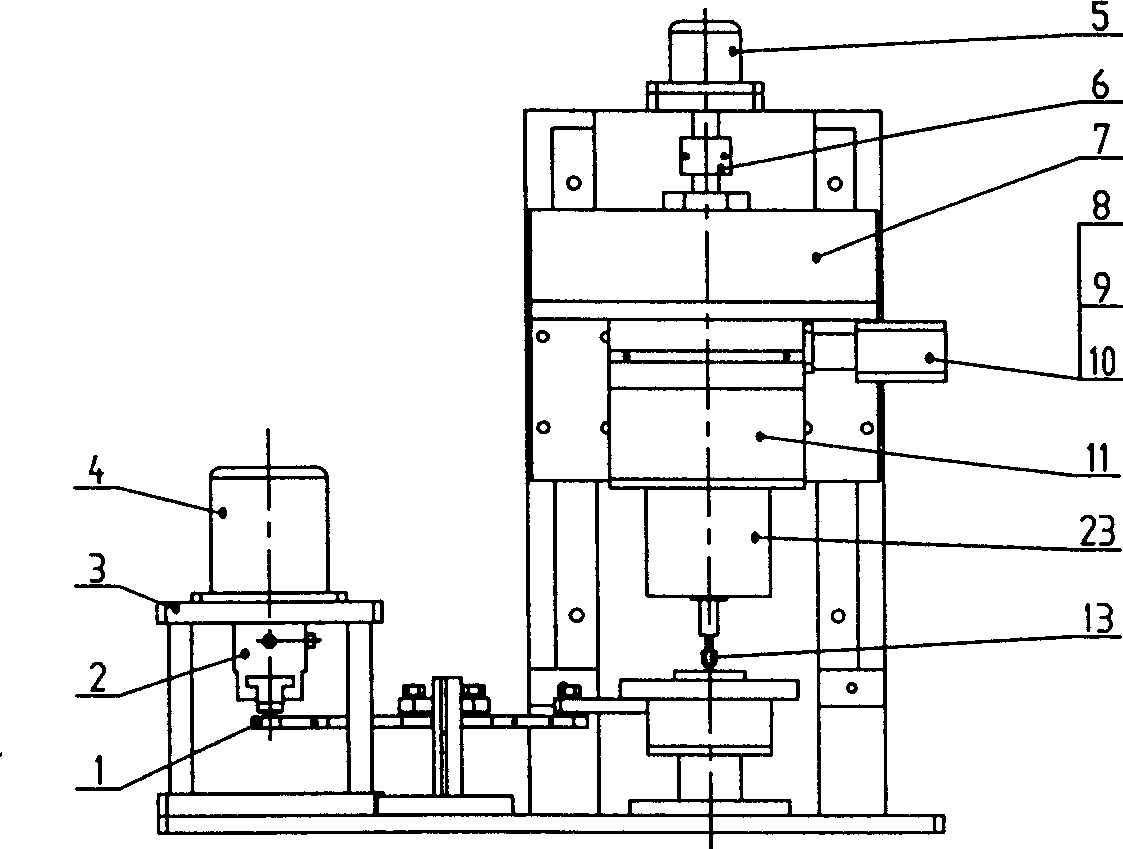

[0023] Embodiment two: Figure 4 Figure 5 As shown, the mechanism components are basically the same as the first embodiment, the difference is that the movement device connected with the driving device is composed of a support 25 and a rotating table 24 matched with it, and the lower sample 19 is fixed on the rotating table 24, corresponding to The sensor in the loading and measuring device provided on the turntable 24 is a torque sensor 23 . The turntable 24 is hinged with the connecting rod 20, and twists back and forth together with the connecting rod 20, so that the lower sample 19 and the upper sample 13 generate twisting friction and wear motion, and the magnitude of the torque is detected by the torque sensor 23.

Embodiment 3

[0024] Embodiment three: Figure 6 Figure 7 As shown, the mechanism components are basically the same as in Embodiment 1, the difference is that the connecting rod 26 of the driving device is directly hingedly connected with the slide table 14 of the moving device, and the driving device is located close to the side of the moving device, and the bracket 21 and the moving device are removed. The cantilever elastic plate 22 arranged on the support 21 can make the slide table 14 get a relatively large linear reciprocating motion due to the reduction of the proportional amplification link of the cantilever elastic plate in the middle, so that a gap between the lower sample 19 and the upper sample 13 can be generated. The magnitude of the frictional force of the larger-amplitude frictional wear motion is detected by the force sensor 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com