Detectable flow electromagnetic valve

A solenoid valve and flow rate technology, applied in the field of automation, can solve the problems that the oil-filled solenoid valve does not realize the fuel flow measurement and control, the oil-filled solenoid valve does not have the flow sensing function, and cannot realize the real-time control of the fuel flow. Easy maintenance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

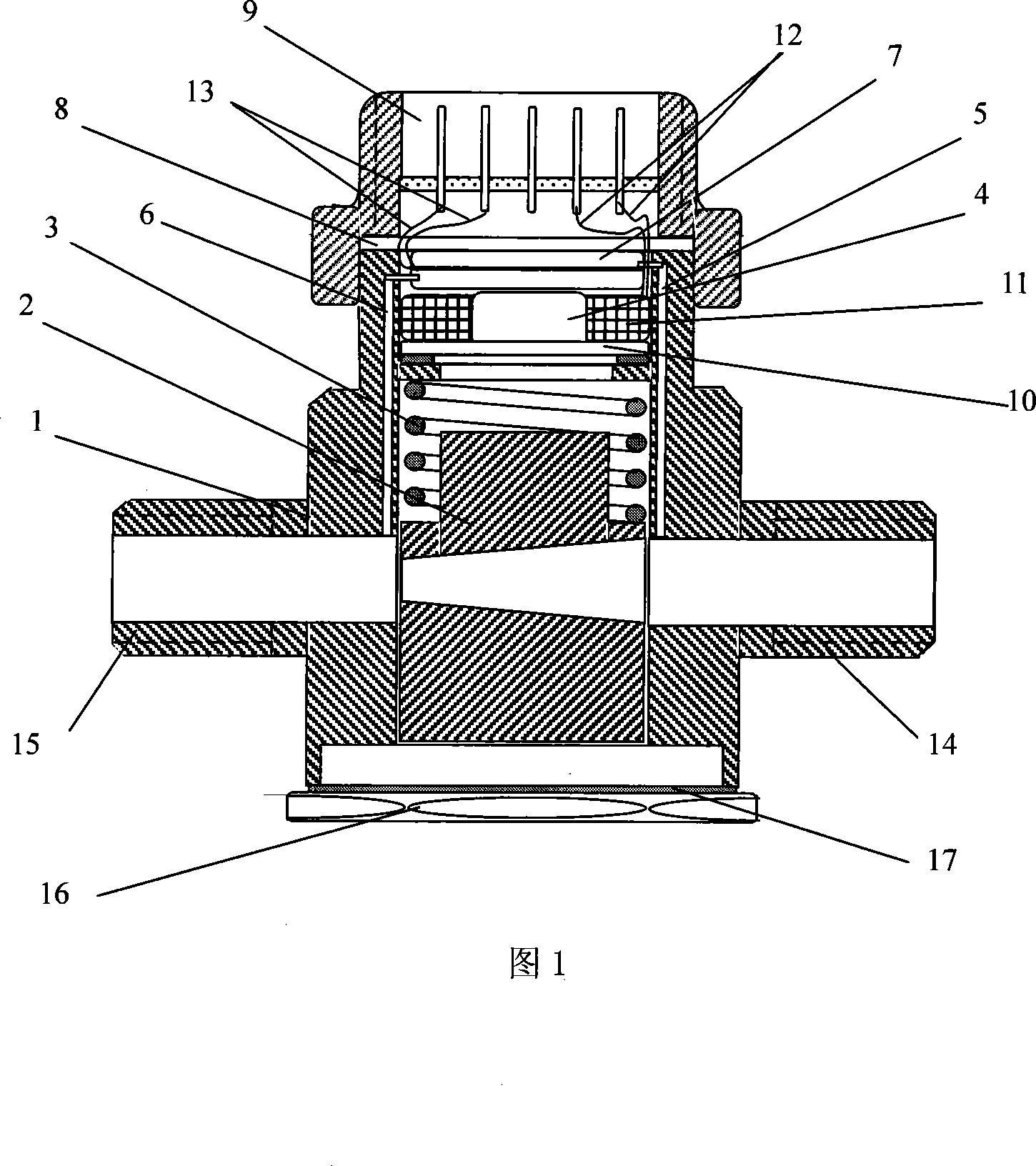

[0015] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0016] As shown in Figure 1, this embodiment includes: solenoid valve body 1, valve 2, compression spring 3, electromagnet 4, upstream pressure guiding hole tube 5, downstream pressure guiding hole tube 6, differential pressure sensor 7, plastic soft pressure plate 8 , cable interface 9, solenoid valve body 1 is a shell structure, its interior is hollow, and there are upstream pipe joints 14 and downstream pipe joints 15 on the left and right sides of the outside, and the two ends of the fluid channel are connected with the upstream and downstream pipes through them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com