Automatic computerized selecting optimized dredging method for cutter suction dredger

A cutter suction dredger and computer technology, which is applied in the field of automatic optimization of cutter suction dredger computer aided dredging, can solve problems such as capacity and level differences affecting dredging output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

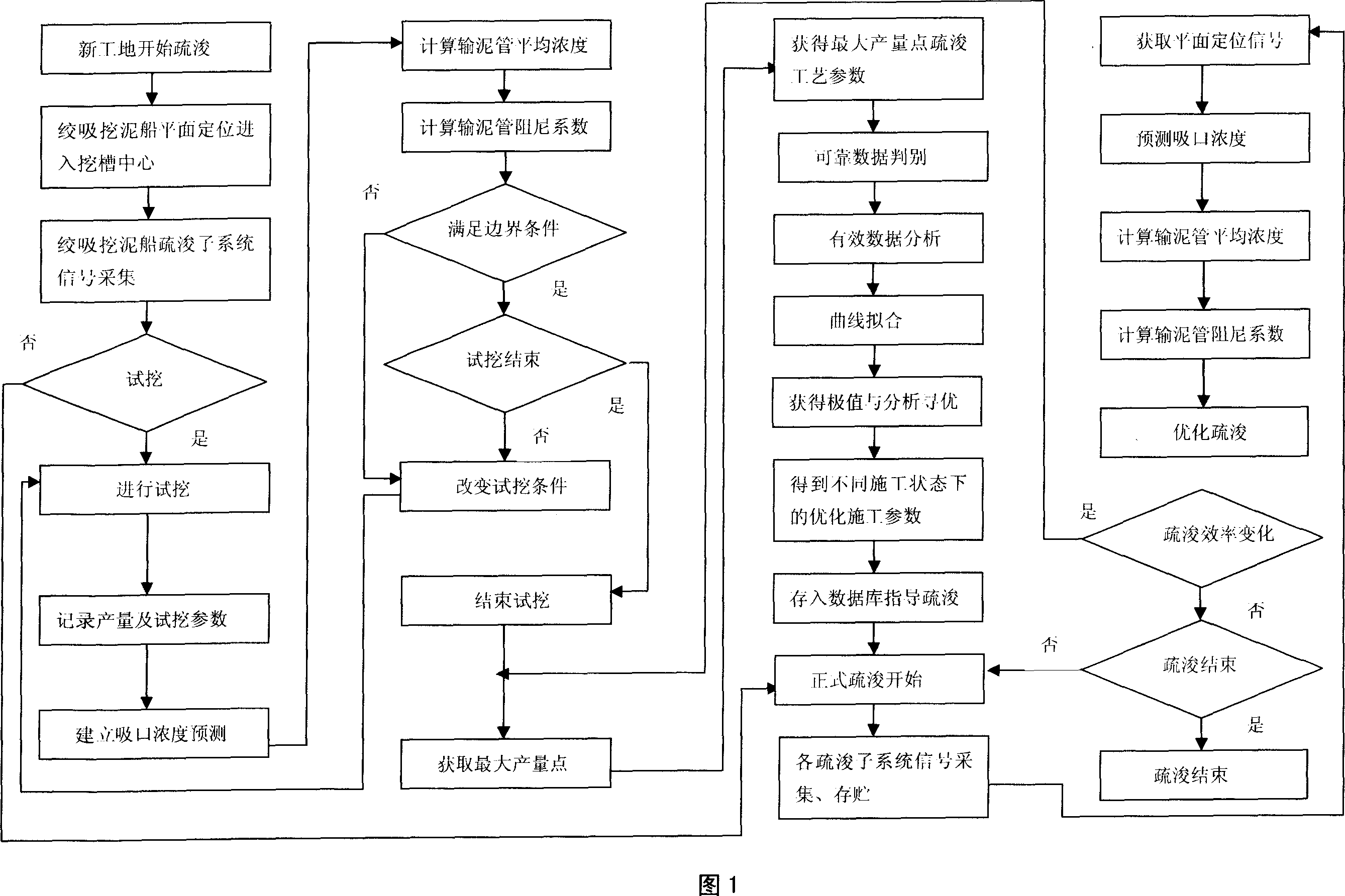

[0069] The method flow of the present invention is shown in Figure 1:

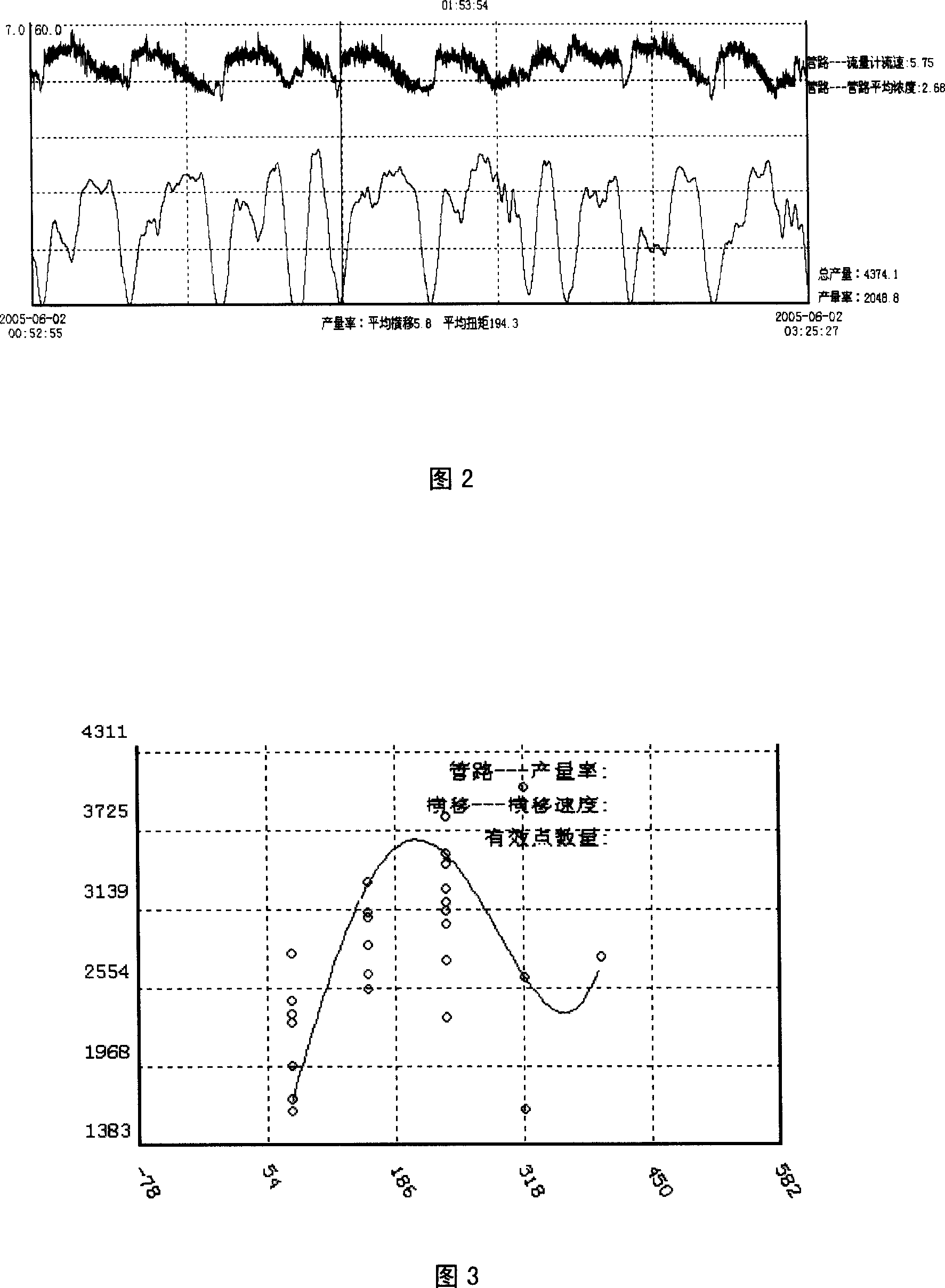

[0070] Before the formal dredging construction, the cutter suction dredger enters the center of the trench, the positioning pile is placed on the center line of the trench through the plane positioning system, and the signals of each dredging subsystem of the cutter suction dredger are collected for trial excavation. Since the trial excavation and dredging process is greatly affected by water flow, wind direction, and inequality and uncertain factors at the bottom of the original riverbed, the raw data continuously collected during the dredging process is a set of oscillating and unstable data (as shown in Figure 2).

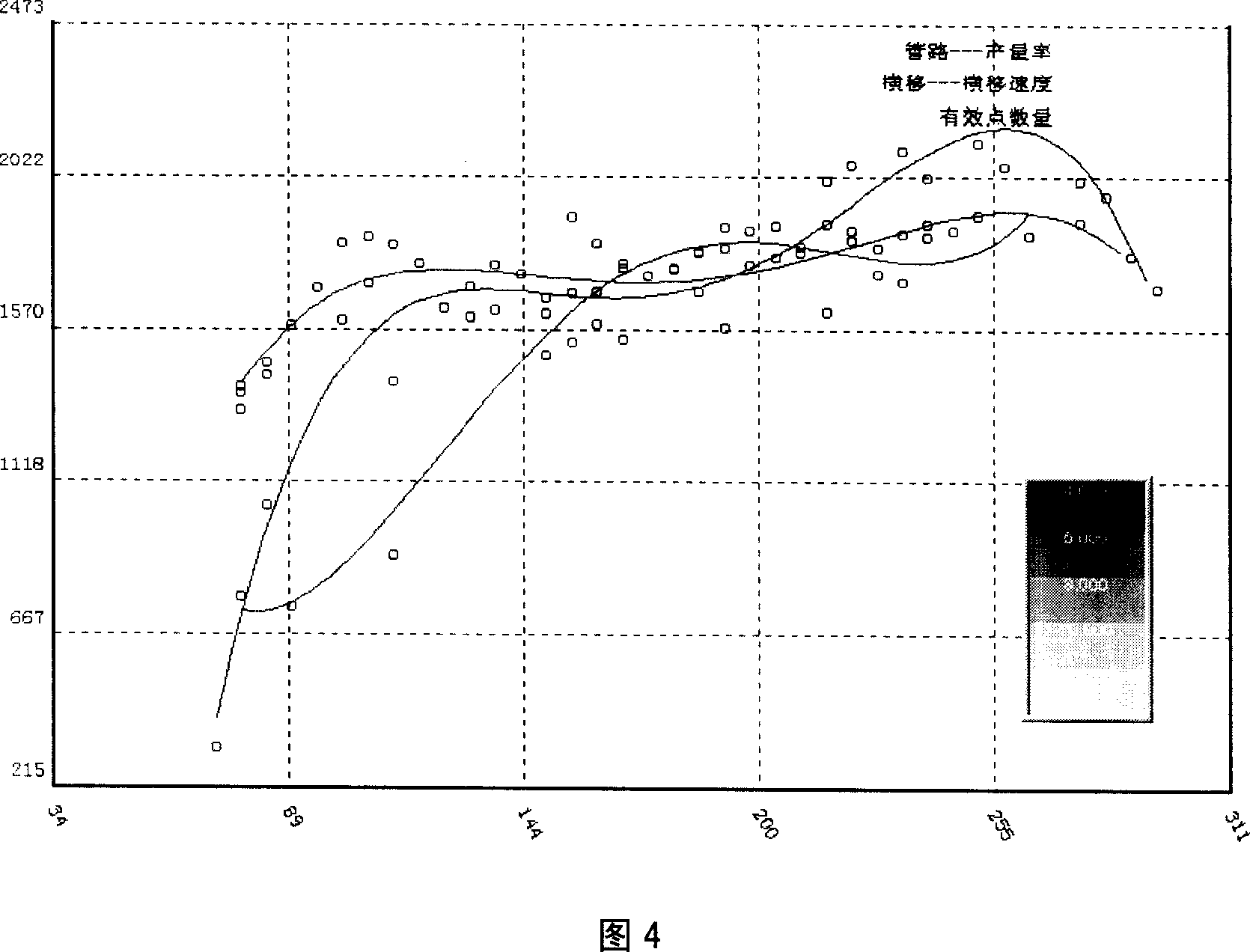

[0071] The system uses mathematical statistical analysis on the oscillation data to obtain true, reliable and smooth results. Set the section for each data that needs to be analyzed. For example, the traverse speed varies from 0m / min to 16m / min. The system divides this 16m / min interval into 40 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com