Three-dimensional network for chemical mechanical polishing

A network structure, three-dimensional technology, applied in the field of polishing pads, can solve the problem of not developing materials and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

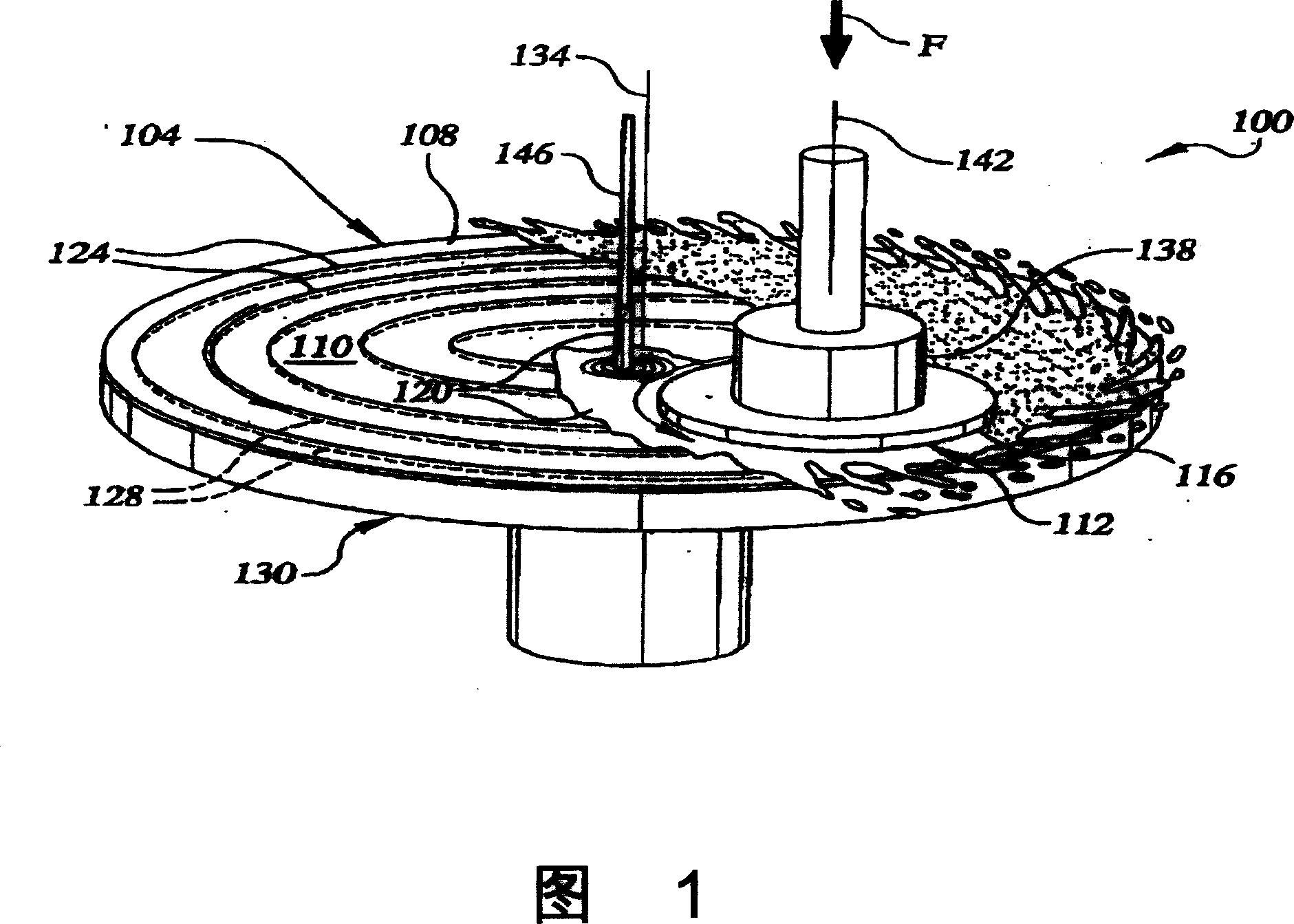

[0022] Referring to the drawings, FIG. 1 generally depicts the main features of a dual-axis chemical-mechanical polishing (CMP) machine 100 suitable for use with a polishing pad 104 of the present invention. The polishing pad 104 generally includes a polishing layer 108 having a polishing surface 110 facing an article such as a semiconductor wafer 112 (processed or unprocessed) or other workpiece such as glass, a flat panel display or a magnetic information recording disc, etc., The polishing surface 116 of the workpiece is polished in the presence of the polishing medium 120 . Polishing media 120 moves through optional helical groove 124 having depth 128 . For simplicity, the term "wafer" is used in the general sense below. Furthermore, in this specification (including the claims), the term "polishing medium" includes particle-containing polishing solutions as well as particle-free solutions, such as abrasive-free and reactive liquid polishing solutions.

[0023] The presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com