Cast-in-situ clear-water concrete viewing platform form board and its construction method

A technology of fair-faced concrete and stands, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, podium, etc., which can solve problems such as difficulties in hoisting construction, delay in construction period, and mold expansion, and achieve saving The effect of turnover materials, increased construction speed, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

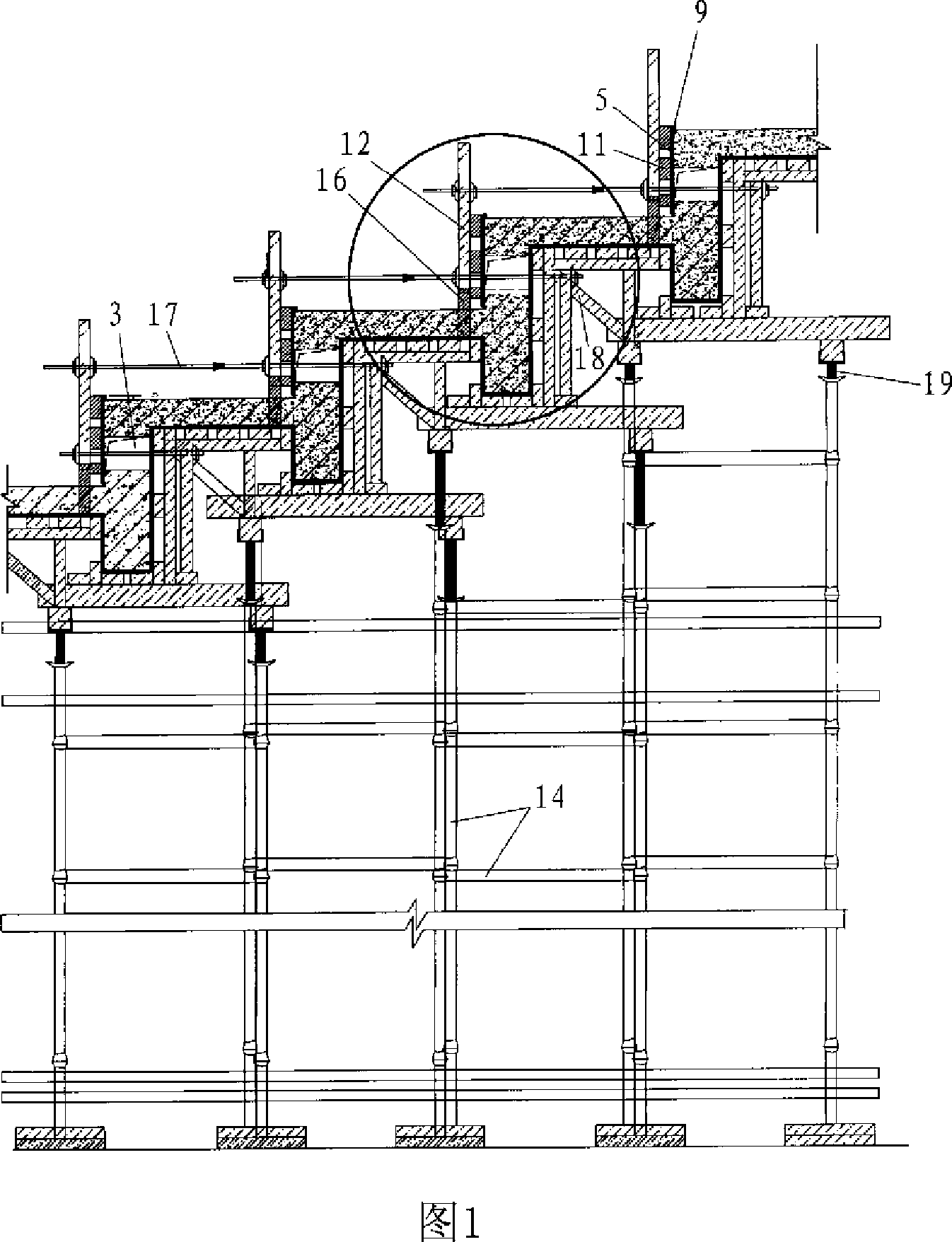

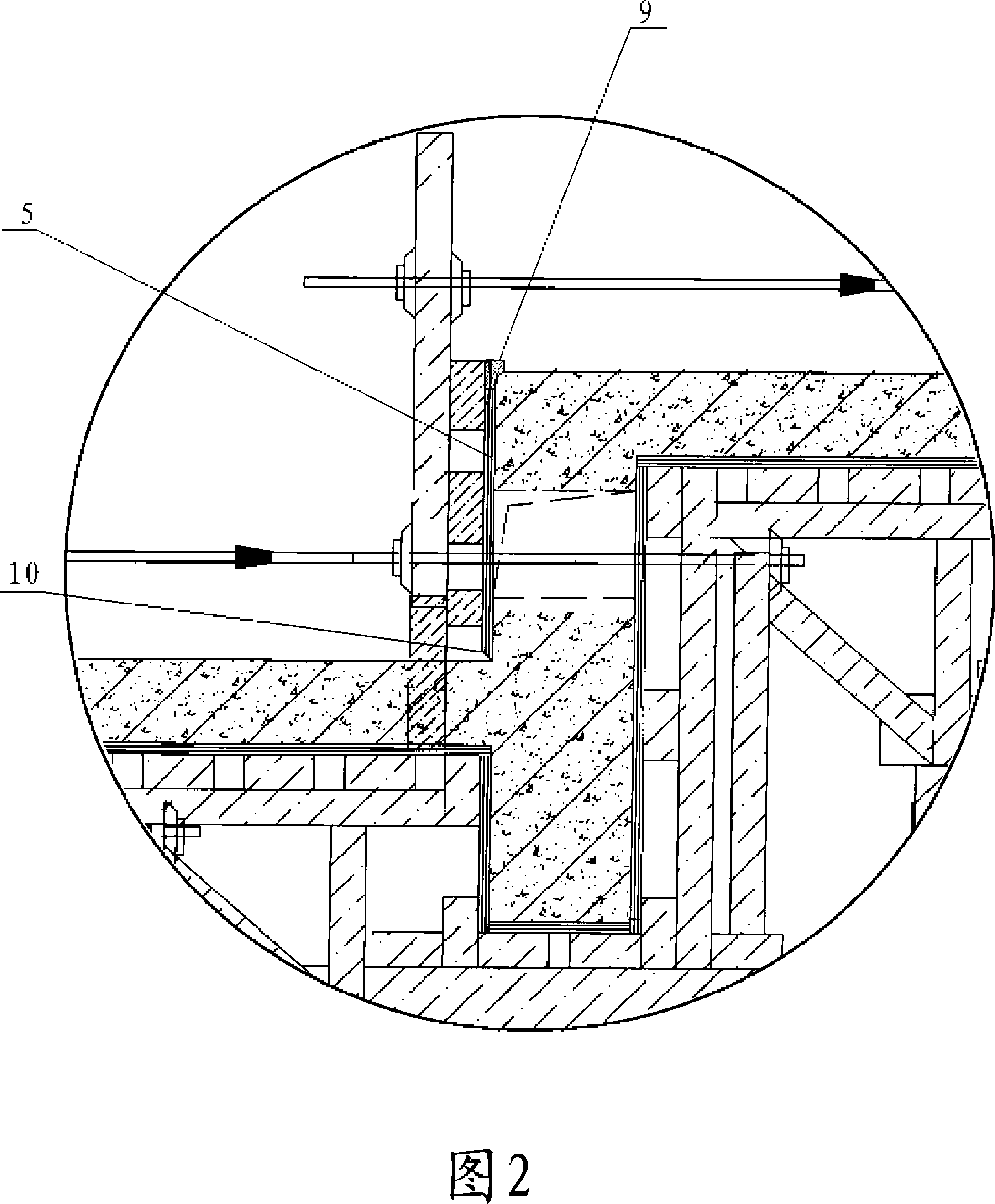

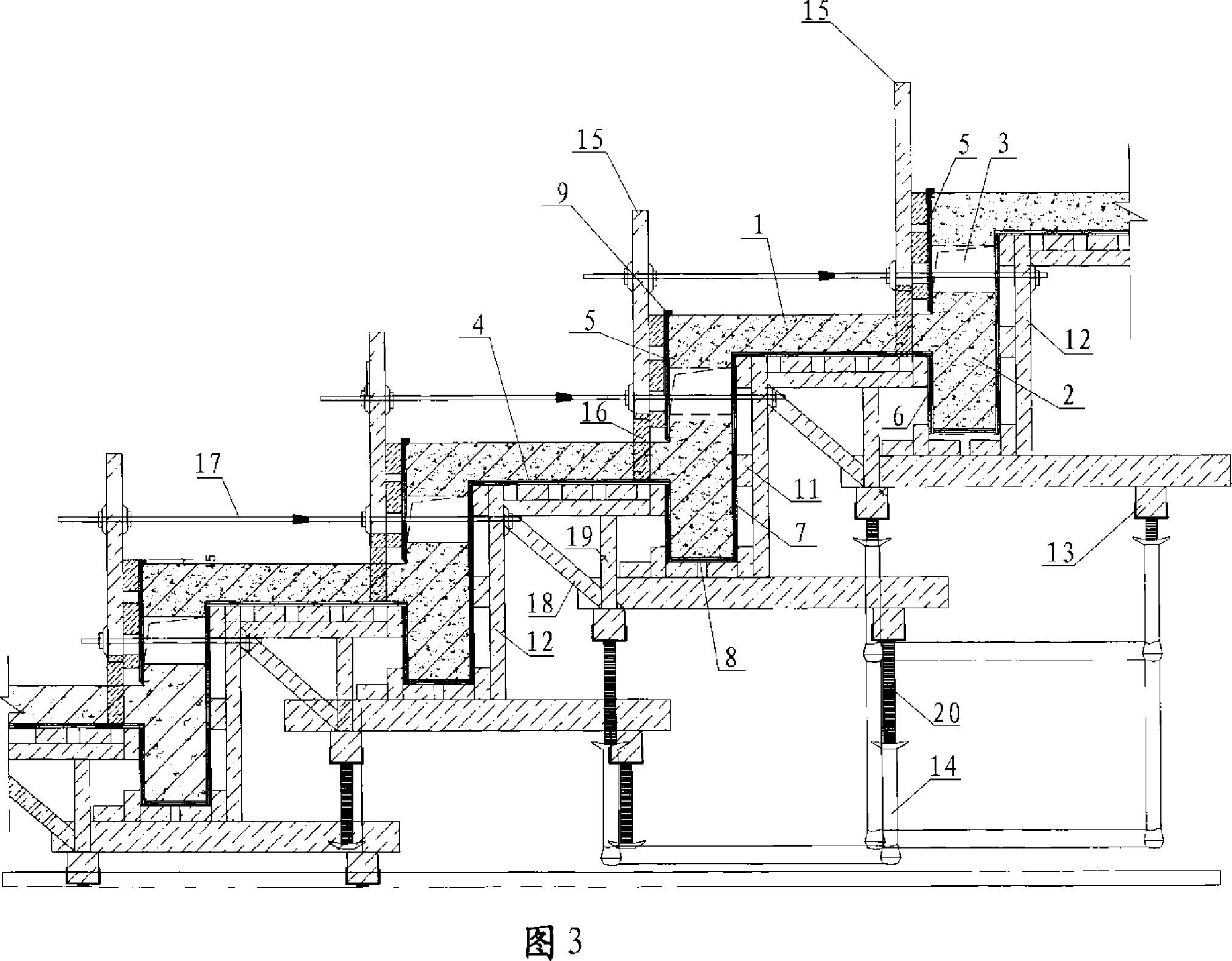

[0046]Refer to Figure 1-5, this kind of cast-in-place concrete grandstand is in the shape of steps as a whole, the width of each step is 850mm, and the height difference between adjacent steps is from 370mm to 780mm. into one. Each step is in the form of a seat platform 1 and a seat back vertical beam 2, and the inner angle between the above two is a right angle; the upper end of the seat back vertical beam of the next step and the outer end of the seat platform of the upper step The building is connected as a whole, and the male corners where the above two are connected are in the shape of circular arc chamfering. The back vertical beam of the seat has a ventilation hole 3 on the part protruding from the seat platform.

[0047] The cast-in-place concrete stand formwork for making the above-mentioned cast-in-place clear-water concrete stand slabs of the present invention includes a formwork panel, a keel supporting the formwork panel and a support frame body, and is character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com