Computation hollowware for anode casting

A technology of anode casting and mold casting, which is applied to casting equipment, manufacturing tools, equipment for supplying molten metal, etc., can solve problems such as increased mechanical and thermodynamic impact, poor anode shape quality, accelerated cracking or sag, etc., to achieve suppression of casting Effects of attaching, reducing kinetic energy, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

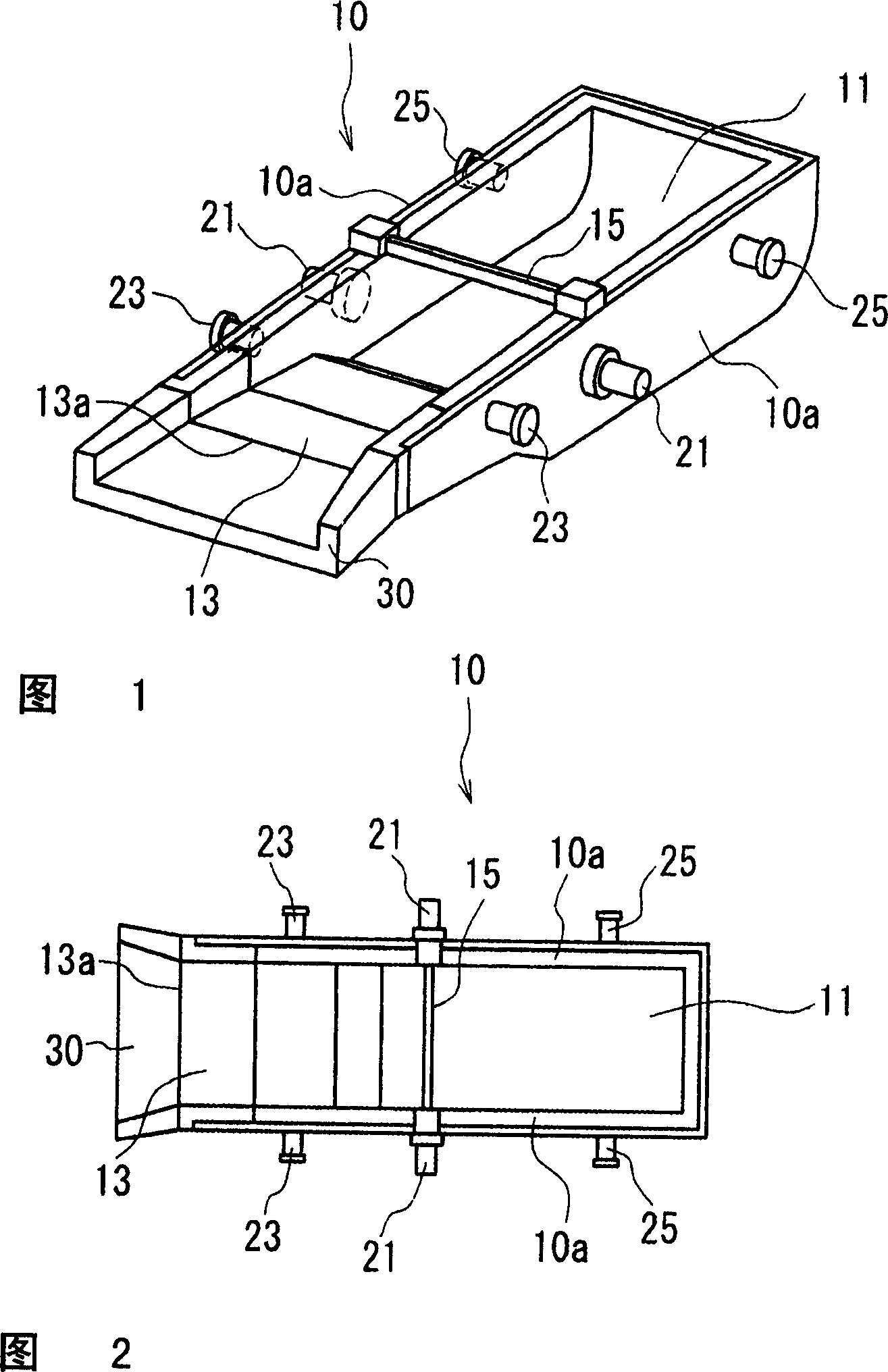

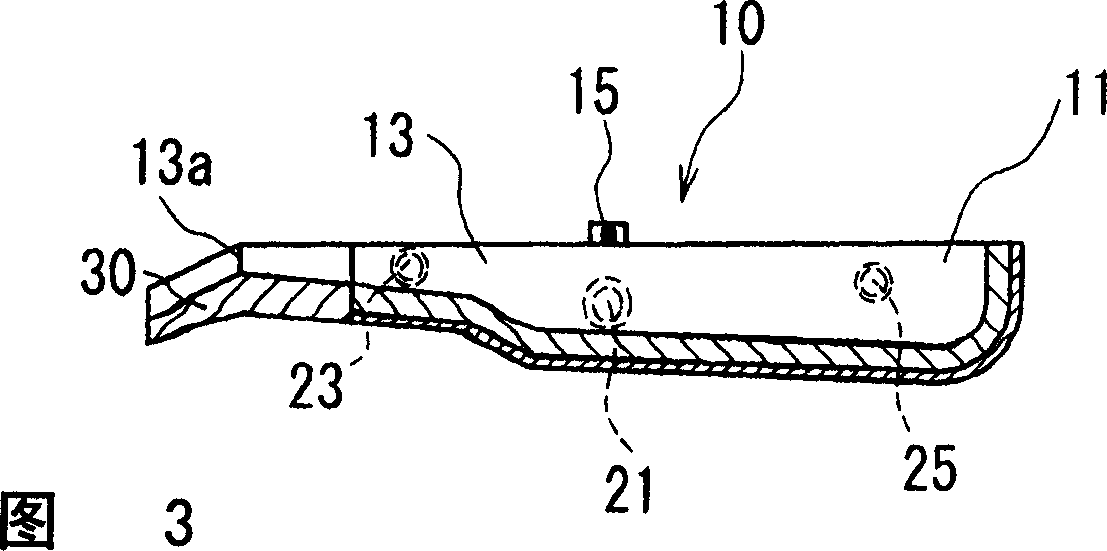

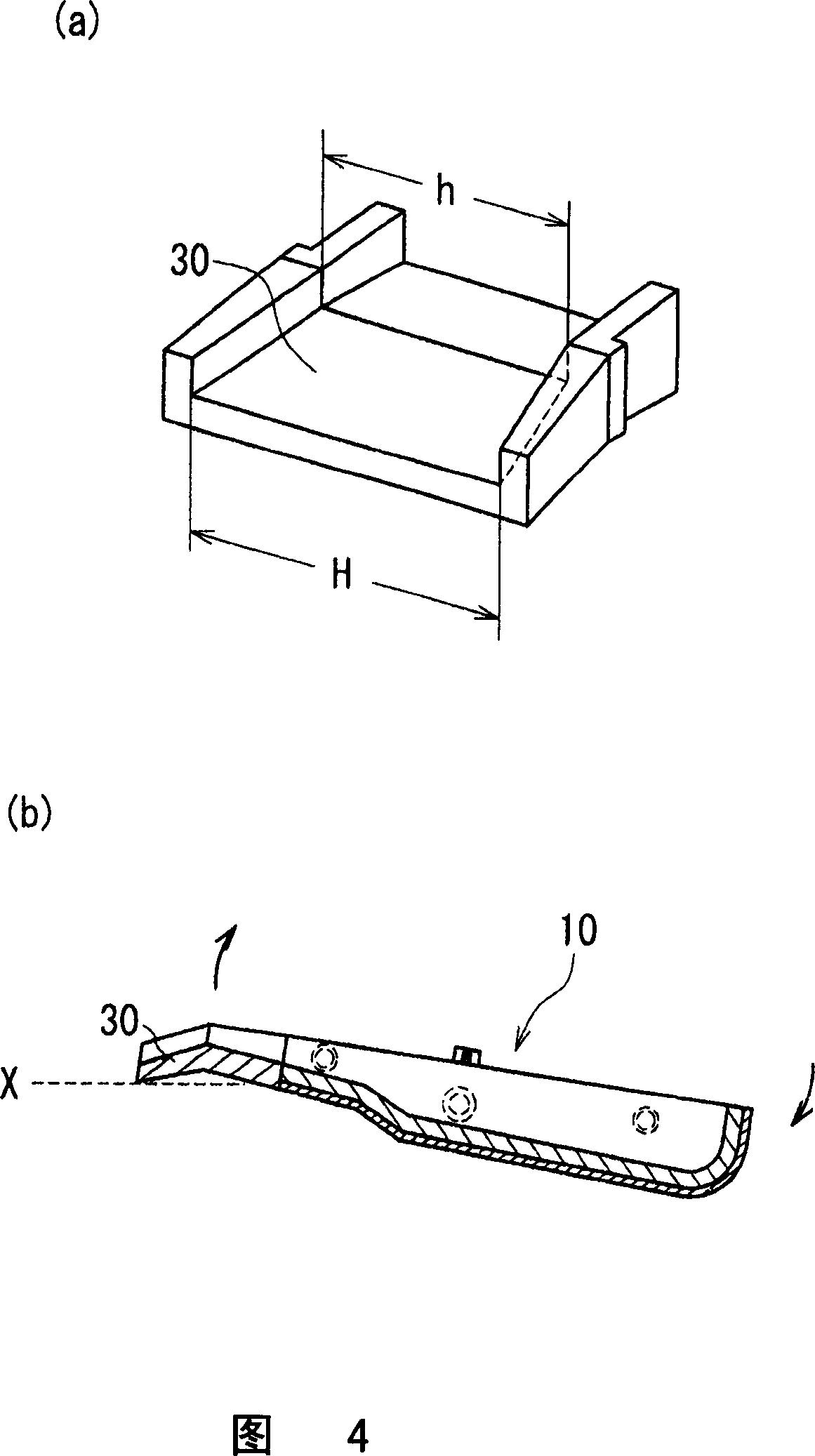

[0035] Hereinafter, a preferred embodiment of the measuring pot for anode casting according to the present invention will be described in detail with reference to the drawings. Fig. 1 is a perspective view of an embodiment of the measuring pot for anode casting according to the present invention, Fig. 2 is a top view of the measuring pot for anode casting shown in Fig. 1 , and Fig. 3 is a view of the measuring pot for anode casting shown in Fig. 1 side view.

[0036] The overall shape of the metering pot 10 for anode casting shown in the figure is roughly the same as that of the conventional one. The liquid part 11 is adjacent to the liquid injection part 13, and the left end of the liquid injection part 13 in FIG. . Moreover, the bottom surface of the liquid injection part 13 is formed so that the depth may become gradually shallower toward the liquid injection port 13a side.

[0037] On the front and rear of both side wall portions 10a, 10a of the measuring pot 10, there ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com