Air floating upward components and manufacturing method thereof

A manufacturing method and air technology, which is applied in semiconductor/solid-state device manufacturing, furnace components, electrical components, etc., can solve the problems of high cost of assembly man-hours, easy air leakage, and high processing costs, so as to reduce assembly man-hours and reduce processing Hours, the effect of reducing the number of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

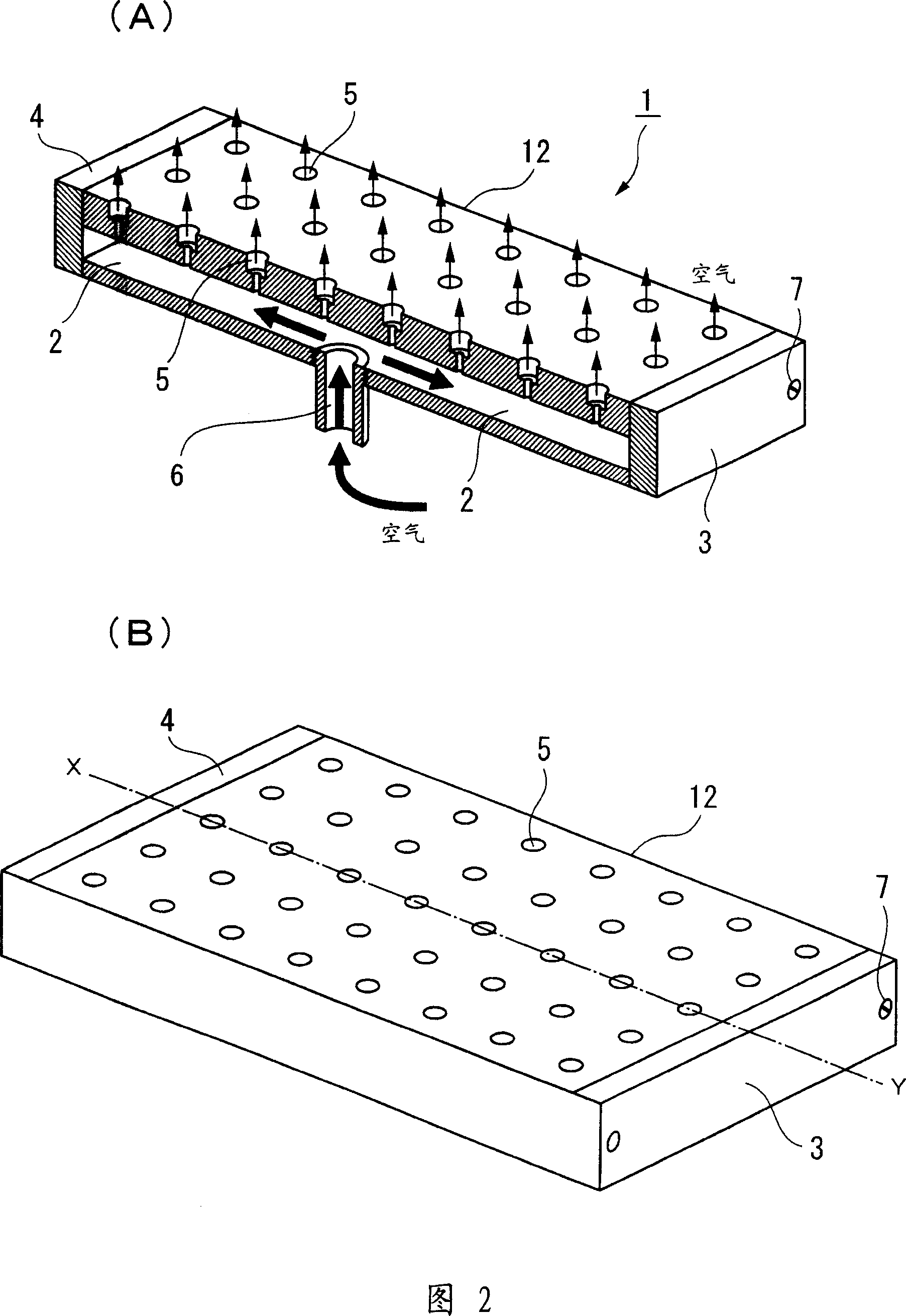

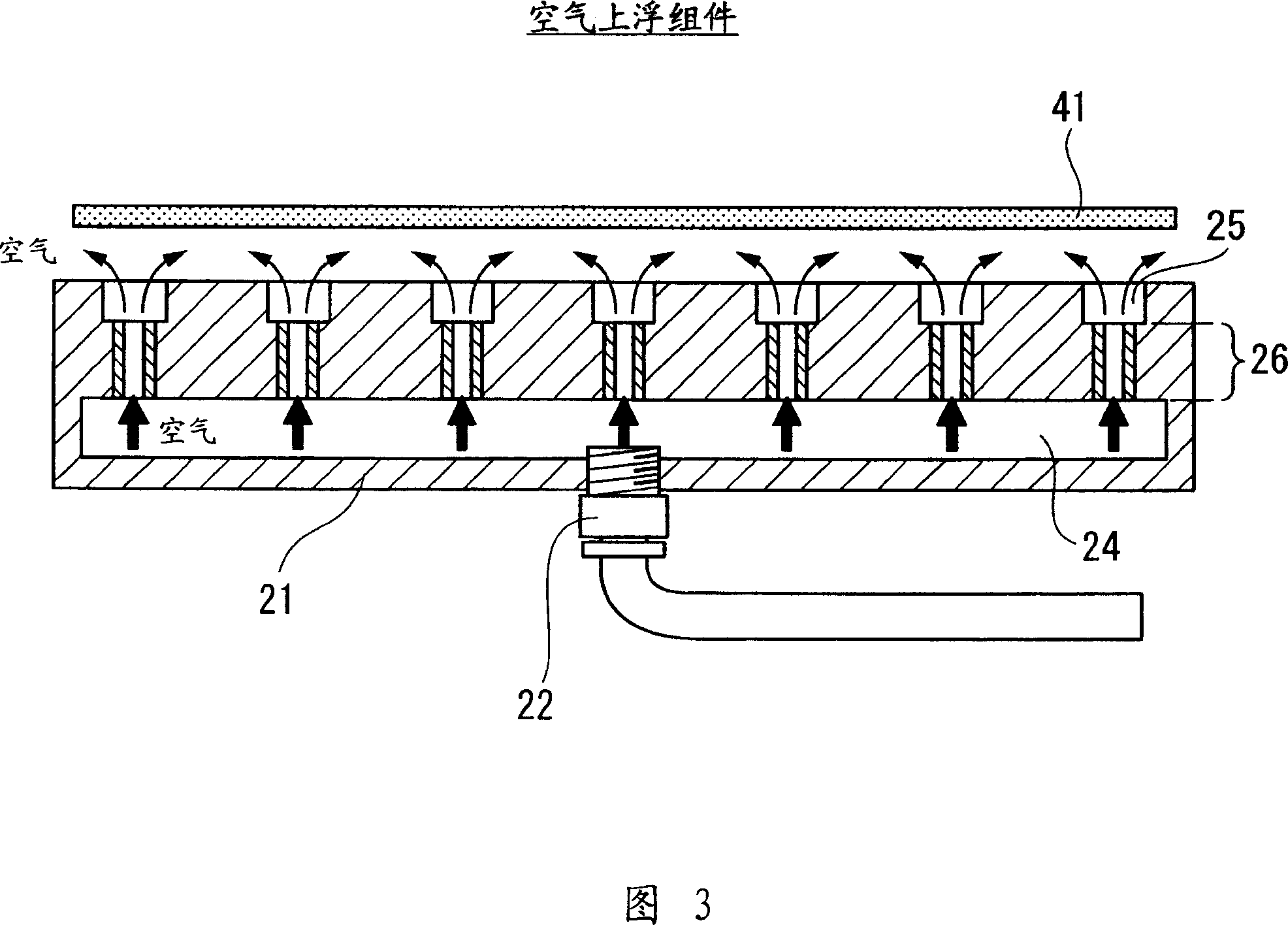

[0036] Preferred embodiments for carrying out the present invention will be described below with reference to the drawings.

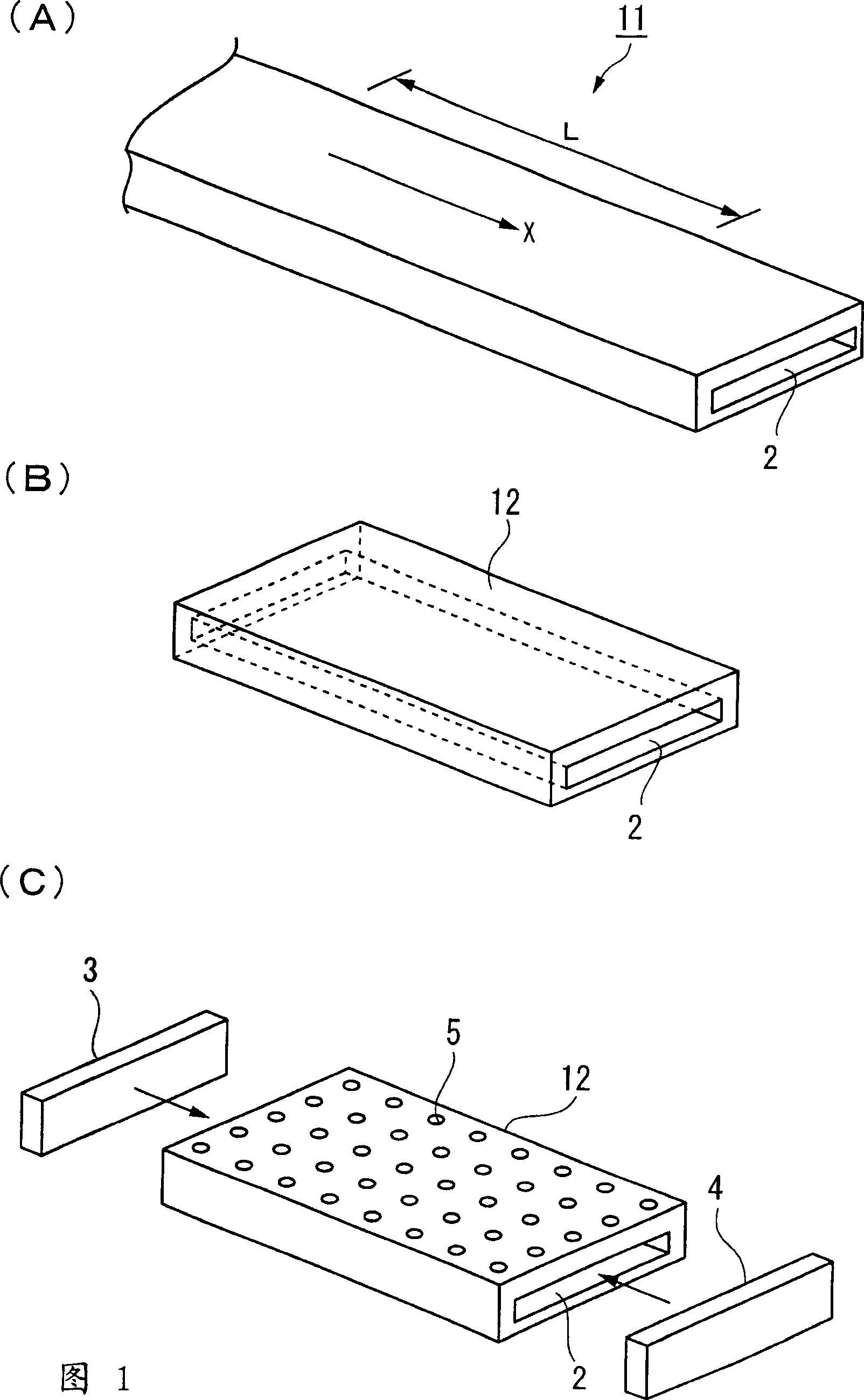

[0037] FIG. 1 is a diagram for explaining a method of manufacturing the air floating unit of the present invention. Hereinafter, the method of manufacturing the air floating unit of the present invention will be described with reference to the drawings.

[0038] First, as shown in FIG. 1(A), an aluminum extrusion profile 11 formed by an aluminum extrusion molding machine is prepared. The aluminum extruded profile 11 has a shape having a hollow portion 2 and is a plate-shaped aluminum material extruded in the arrow X direction. This aluminum extruded profile 11 is cut into a desired dimension L to produce a hollow plate 12 as a base material of an air floating module as shown in FIG. 1(B).

[0039] As shown in FIG. 1(C), the hole processing of the ejection part 5 is performed on the surface of the hollow plate 12, and the processing for providing an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com