Anaerobic reactor

An anaerobic reactor and reactor technology, applied in the field of water treatment, can solve the problems of substandard water output, high manufacturing and maintenance costs, complex reactor structure, etc., and achieve reduced equipment materials and maintenance costs, high removal rate , Enhance the effect of hydraulic turbulence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and the implementation process.

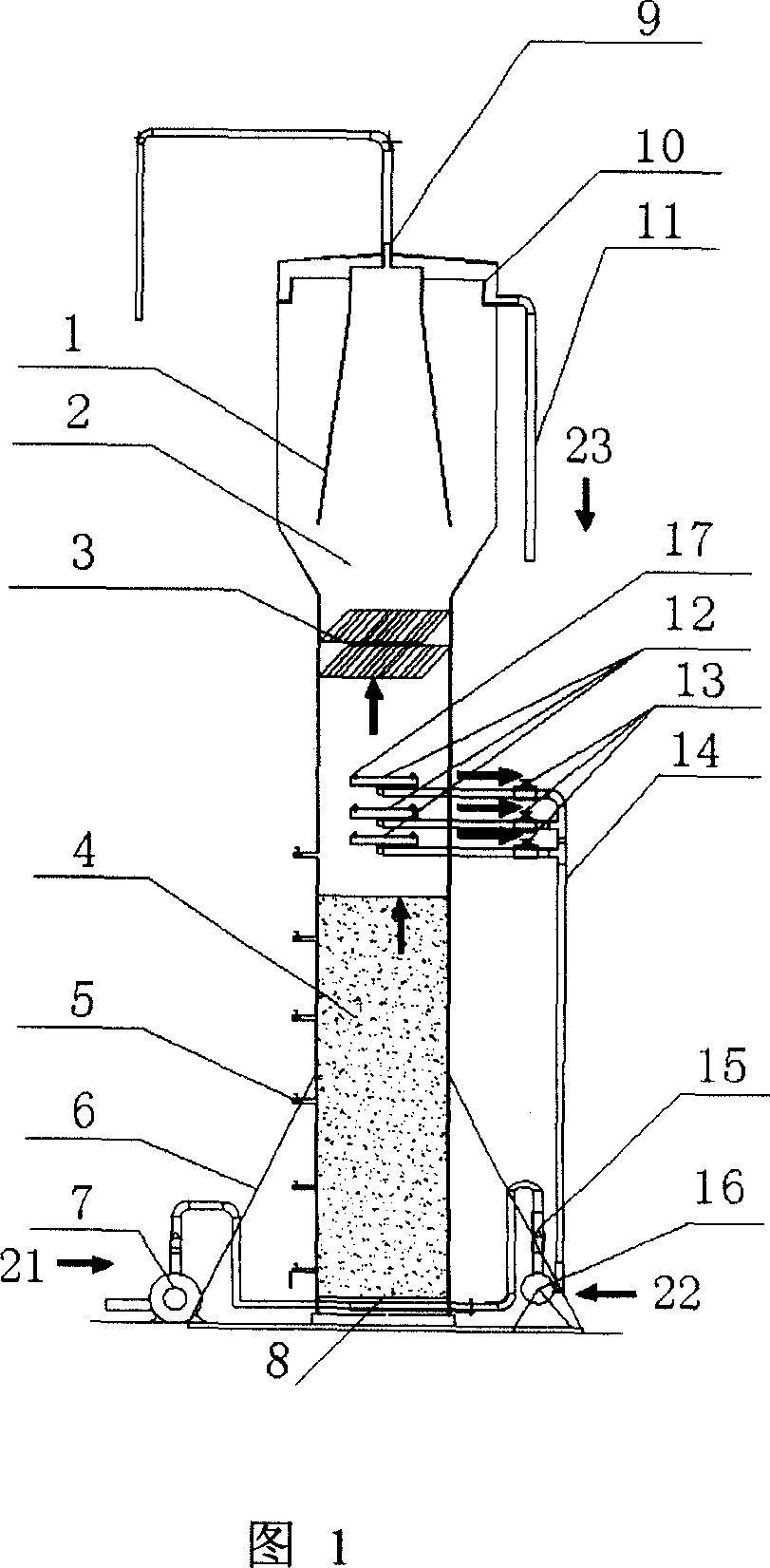

[0027] An anaerobic high-efficiency reactor, which mainly includes: a shell, a supporting base 19, a water distributor, a water distributor, an inclined plate settler, a three-phase separator, a sludge discharge port, a water inlet pump, a circulation pump, a flow meter, overflow tank, etc.

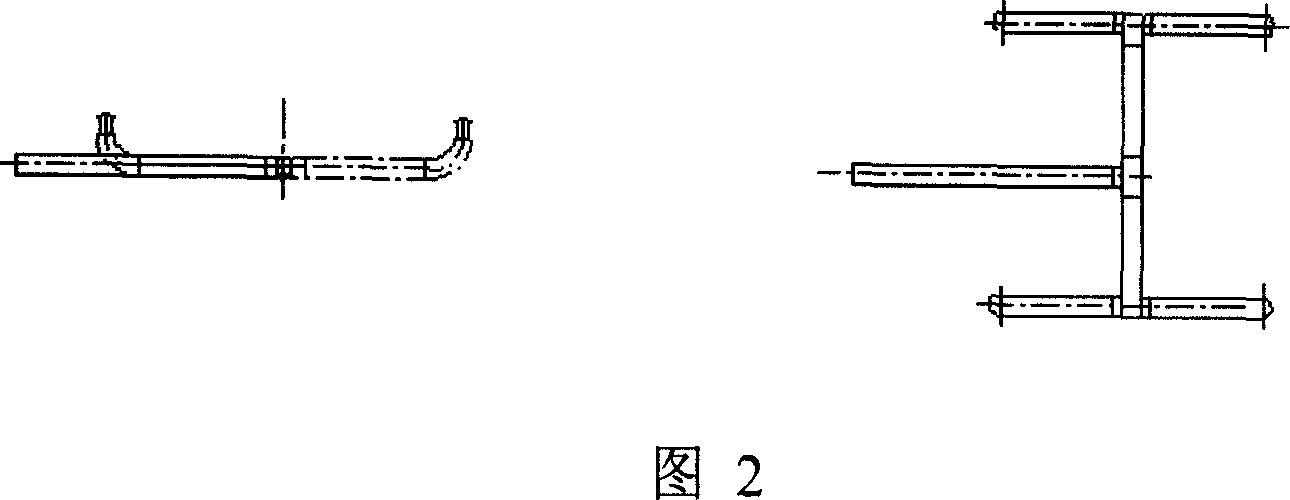

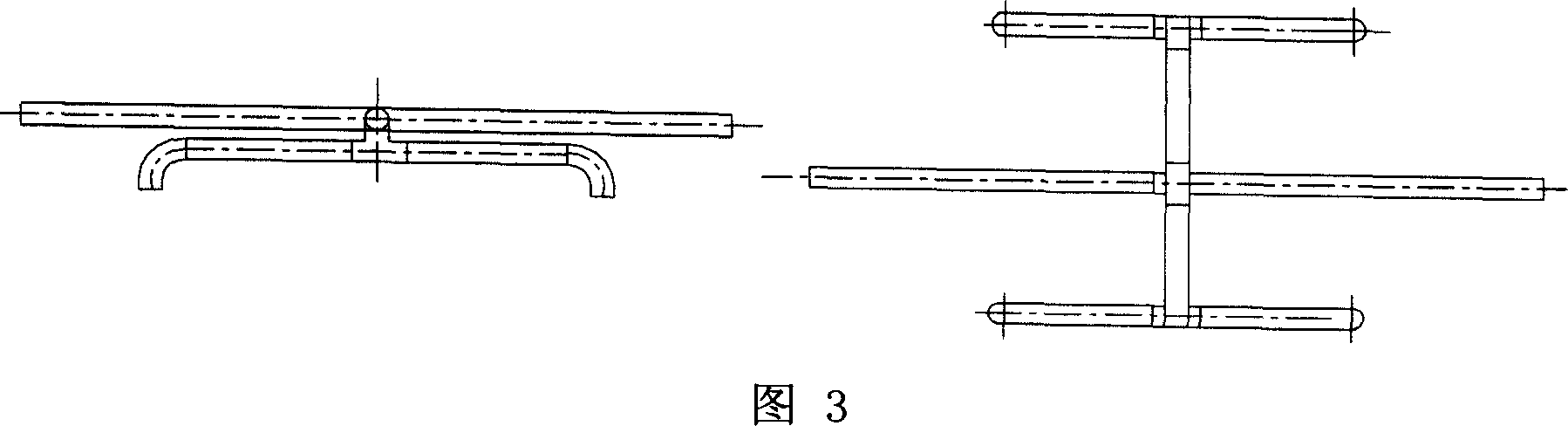

[0028] A set of water distributor and corresponding control valves are installed between the upper end of the expansion zone (4) of the sludge tank and the inclined plate settler (3) (see Figure 2). One end of the water distributor is connected to the water inlet pump, and the other end is connected to the circulation pump (see Figure 3). There is a row of mud outlets along different heights on the reactor shell (see Figure 1); between the water distributor (1) and the three-phase separator (1), a slant plate settler is installed with a gradient of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com