Mortar for building blast furnace stack graphite brick

A technology for graphite bricks and blast furnace furnaces, which is applied in the field of mortar for masonry graphite bricks of blast furnace shafts and graphite bricks for masonry linings of blast furnace shafts, can solve problems such as unfavorable rapid construction, poor thermal conductivity, and lack of strength, and achieves Improve the effect of easy oxidation, enhanced adhesion and high temperature resistance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, by weight, the proportions of the components of the cement are respectively:

[0019] Graphite is 48%, antioxidant metal silicon is 3%, resin binder is 47%, acid curing agent is 2%.

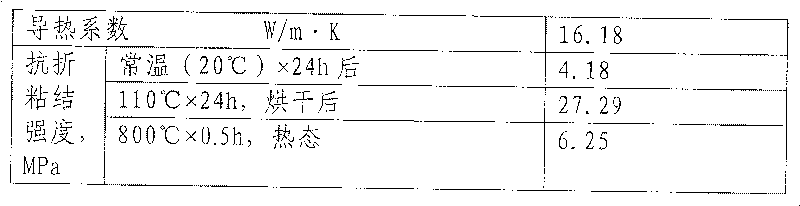

[0020] The thermal conductivity of the graphite cement mixed according to this ratio reaches 16.18W / m K. All other parameters have been tested, and the results are shown in Table 1 below.

[0021] Table 1

[0022]

Embodiment 2

[0024] In this embodiment, by weight, the proportions of the cement are respectively:

[0025] 52% graphite, 3% antioxidant metal silicon, 42% resin binder, and 3% acid curing agent.

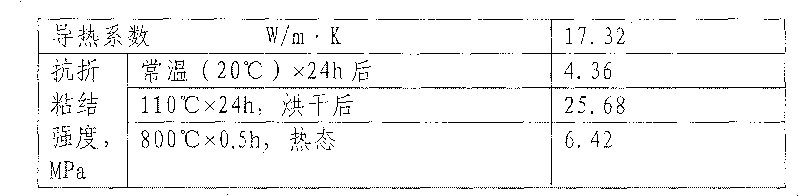

[0026] The thermal conductivity of the graphite cement mixed according to such a ratio reaches 17.32W / m K. The rest of the parameters have been tested and the results are shown in Table 2 below.

[0027] Table 2

[0028]

Embodiment 3

[0030] In this embodiment, by weight, the proportions of the components of the cement are respectively:

[0031] Graphite is 43%, antioxidant metal silicon is 3%, resin binder is 50%, acid curing agent is 4%.

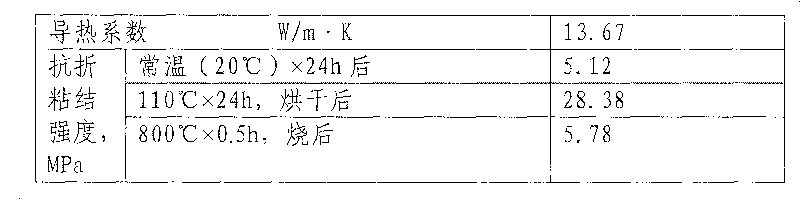

[0032] The thermal conductivity of the graphite cement mixed according to this ratio reaches 13.67w / m·k. The rest of the parameters have been tested and the results are shown in Table 3 below.

[0033] table 3

[0034]

[0035] The graphite glue made according to the above-mentioned embodiments of the present invention is applicable to the bonding between the graphite bricks of the furnace body of the blast furnace. The cement can be solidified at normal temperature (20° C.) and produce strength, which is beneficial to construction due to its high thermal conductivity. 110 The characteristics of high thermal strength in the temperature range of -800°C enable this graphite cement to continuously maintain the overall strength and overall high thermal conductivity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com