Method of liquefying natural gas and apparatus thereof

A natural gas, gas-liquid two-phase flow technology, applied in the direction of liquefaction, refrigeration and liquefaction, gas fuel, etc., can solve the problem of no method and practical device, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

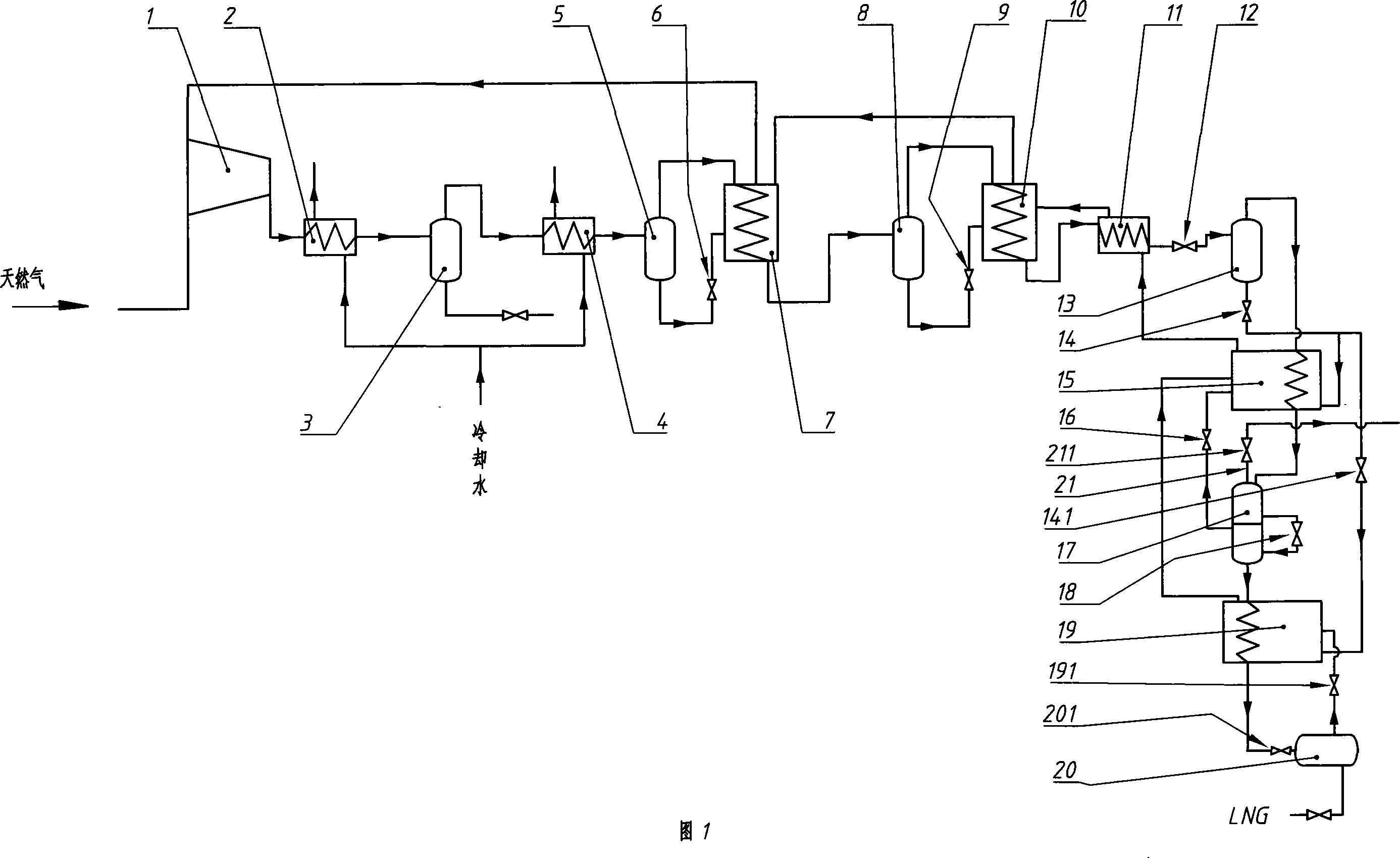

[0045] A process for the liquefaction of natural gas using a compressor and a refrigerant. Only one compressor is needed in the method of the invention, and the refrigerant of the invention is a circulating refrigerant mixed with propane, ethylene and methane. The weight mixing ratio of propane, ethylene and methane was 1.76:1.27:1.0.

[0046] Its natural gas liquefaction process includes:

[0047] a. A step of sucking raw natural gas from which impurities have been removed and circulating refrigerant into the compressor for compression. In this step, the outlet pressure of the compressor is 3.0Mpa-4.0Mpa, and the outlet temperature is 120°C-140°C.

[0048] b. Cool the high-temperature and high-pressure mixed gas output from the compressor, and then separate the heavy hydrocarbon component brought from the raw natural gas and condensed into liquid after cooling from the mixed gas, and remove the heavy hydrocarbon Component steps. In this step, the temperature of the cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com