Core directional enhancement solid wood mixing floor

An oriented strand board and solid wood technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of insufficient utilization of wood resources, low wood utilization rate of composite floors, poor sound insulation performance of composite floors, etc., to fill the market gap, Low production cost and good sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

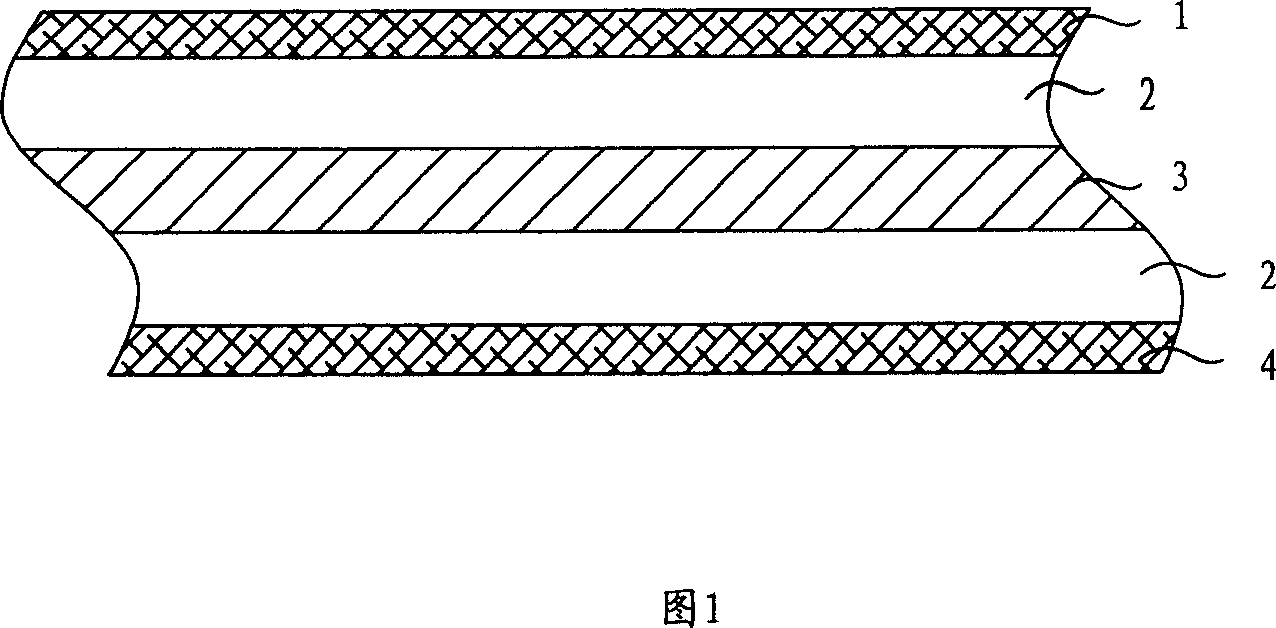

[0029] FIG. 1 is a schematic structural diagram of Embodiment 1 of the present invention. As shown in Figure 1, the decorative panel 1, the particle board 2, the core board 3, the particle board 2 and the decorative backboard 4 are sequentially laminated to form the structure of this embodiment. Compression molding. The decorative panel 1 is a solid wood veneer decorative layer, which is used as the floor surface and has the characteristics of natural surface texture and strong sense of reality; the decorative back panel 4 is the back of the floor, which is used to balance the wooden floor so that it is not easy to deform; the center core board 3 is used as the central strengthening member, High-density fiberboard or medium-density fiberboard can be used, clamped between the particleboards in a sandwich shape, connecting the upper and lower structures, and enhancing the overall strength of the floor; the material of the particleboard 2 is completely taken from artificial fast-...

Embodiment 2

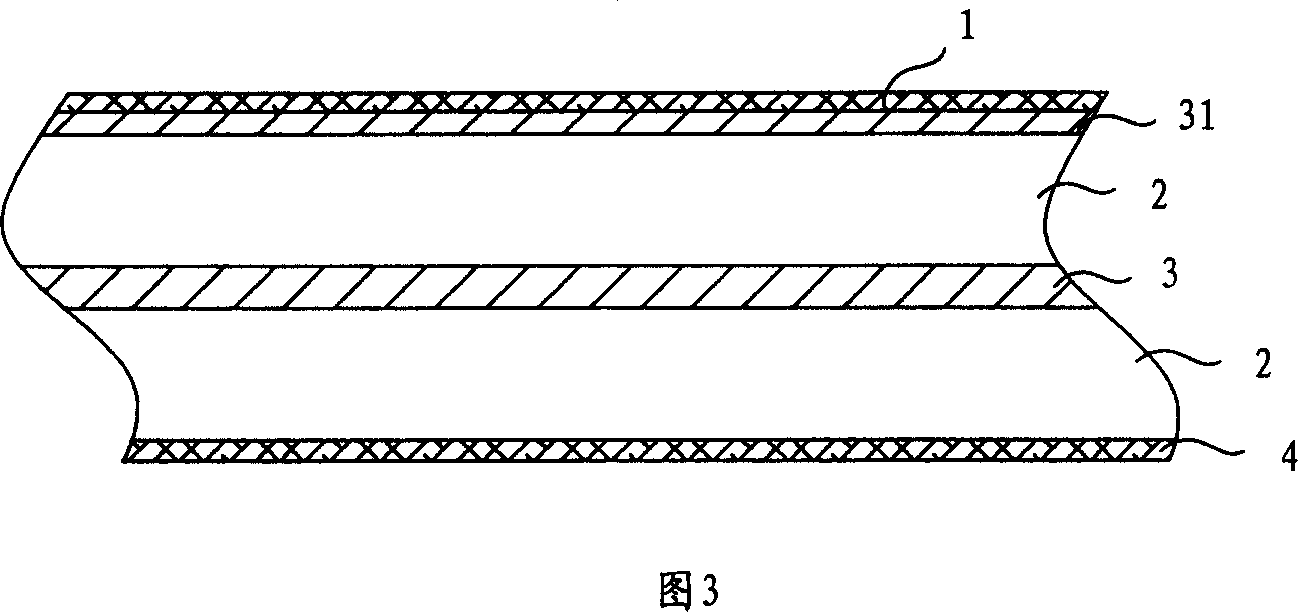

[0035] Fig. 3 is a schematic structural diagram of Embodiment 2 of the present invention. As shown in FIG. 3 , the decorative panel 1 , the thin core board 31 , the particle board 2 , the core board 3 , the particle board 2 and the decorative back board 4 are sequentially laminated to form the structure of this embodiment. Different from the technical solution shown in the first embodiment, a thin core board 31 is also laminated between the decorative panel 1 and the particle board 2 . In addition to the advantages of the first embodiment, this embodiment has the thin core board 31 between the decorative panel 1 and the particle board 2, on the one hand the overall strength of the floor is improved, especially the compressive strength of the floor surface, and on the other hand On the one hand, it can make the decorative panel 1 have higher flatness, and improve the external beauty of the product.

Embodiment 3

[0037]Fig. 4 is a schematic structural diagram of Embodiment 3 of the present invention. As shown in FIG. 4 , the decorative panel 1 , the particle board 2 , the core board 3 , the particle board 2 , the thin core board 31 and the decorative back board 4 are sequentially laminated to form the structure of this embodiment. Different from the technical solution shown in the first embodiment, a thin core board 31 is also laminated between the decorative back board 4 and the particle board 2 . In addition to the advantages of Embodiment 1, this embodiment has the thin center core board 31 added between the decorative backboard 4 and the particle board 2. On the one hand, the overall strength of the floor is improved, and in particular, the strength of the decorative backboard 4 is strengthened. Anti-deformation performance, on the other hand, increases the moisture-proof and water-resistant performance of the entire floor, and improves the service life of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com