Mountain massif shaft-well chimney highly effective solar energy hot gas flow generating system

A power generation system, solar thermal technology, applied in solar thermal power generation, wind power generation, mechanical power generated by solar energy, etc., can solve the problems of short service life, small temperature difference of heat collection shed, poor thermal insulation performance, etc., and achieve no damage to the ecological environment , fast construction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

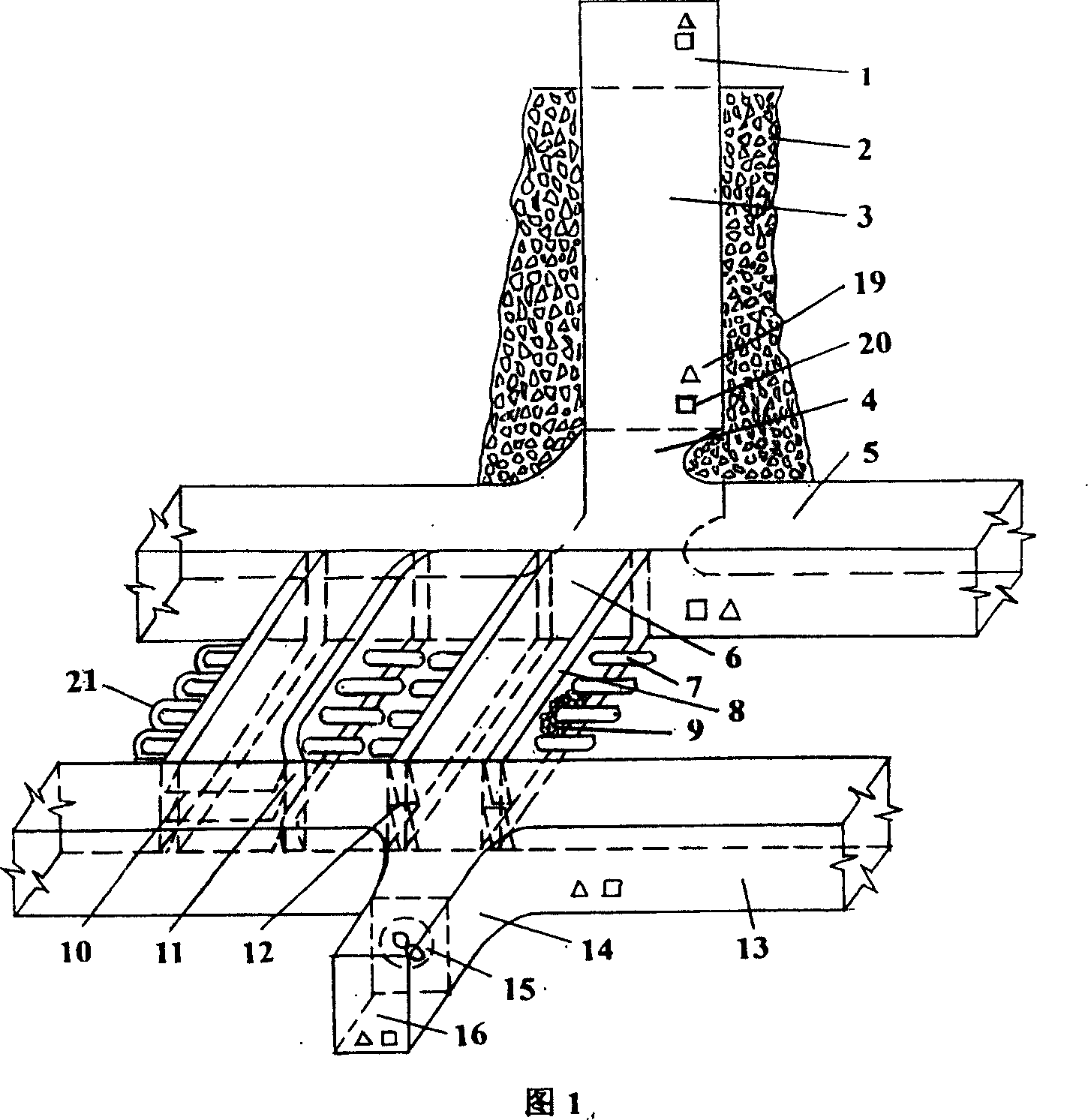

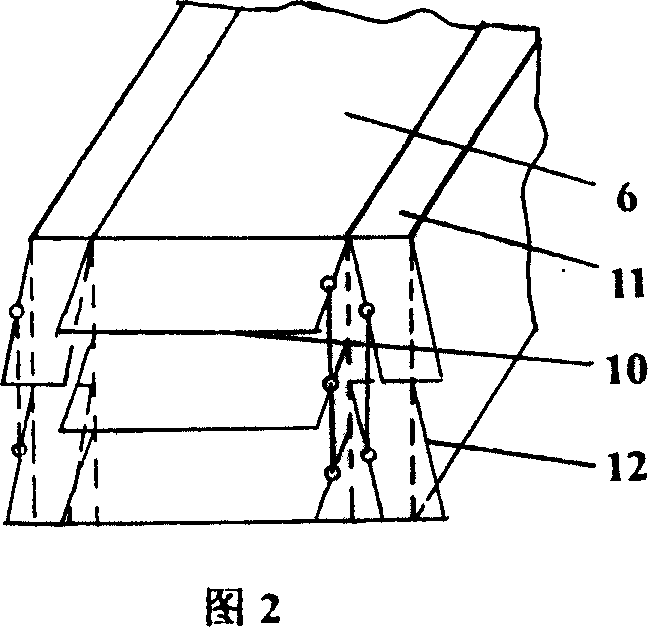

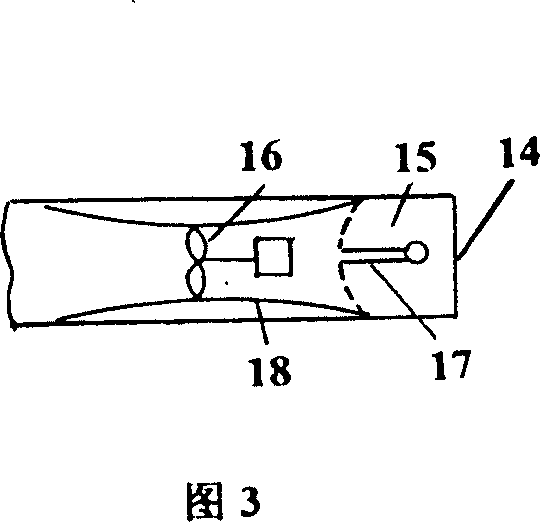

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes the hot air duct system of the heat collection and storage unit, the hot air collection system of the heat collection and storage unit on the slope of the mountain, and the power generation system.

[0017] The hot air duct system of the present invention comprises a mountain body 2, a mountain top chimney 1 located at the top of the mountain body 2, a mountain chimney 3 located in the mountain body 2, and a mountain flat hole 4, which are successively connected to the upper hot air flow connecting air duct 5 and the mountain slope The hot air duct 6 of the heat collecting and storage unit, the lower end cold air connecting air duct 13 and the cold air inlet air duct 14 . As a result, a solar hot air power generation system that does not consume any energy is formed to generate electricity from the natural flow of cold air to hot air.

[0018] The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com