Valve core of ball valve

A spool and ball valve technology, applied in the field of ball valve spools, can solve the problems of poor processing technology, high cost, weak and unstable combination of wear-resistant and corrosion-resistant layer and ball layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

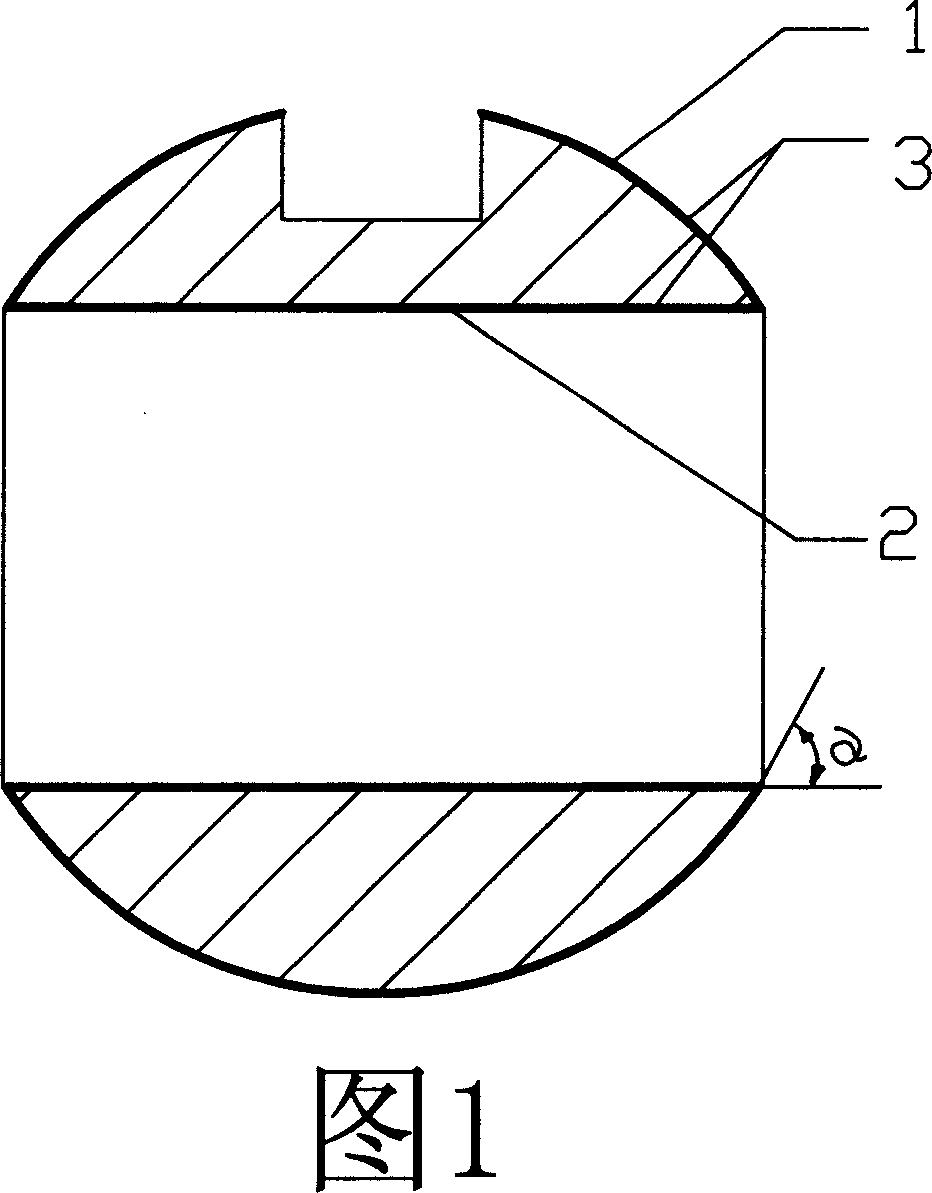

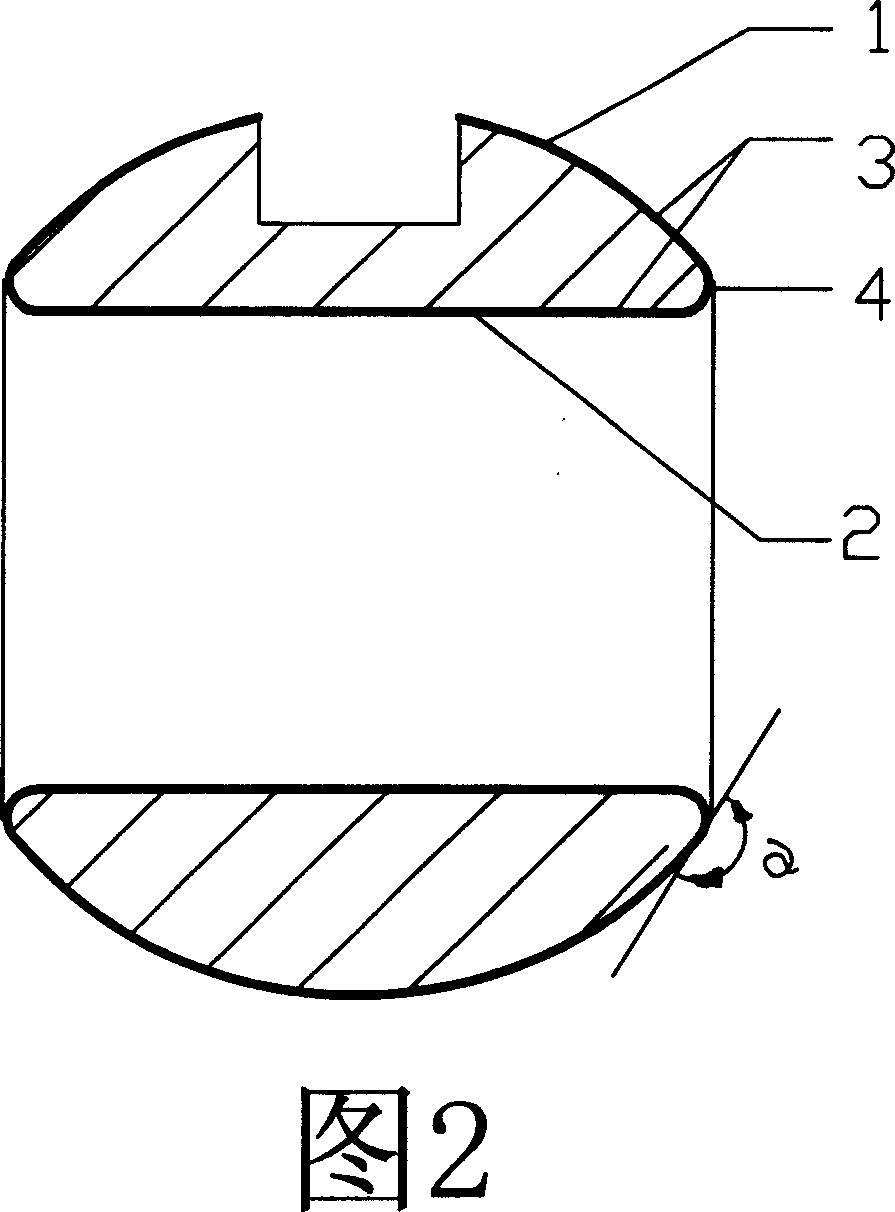

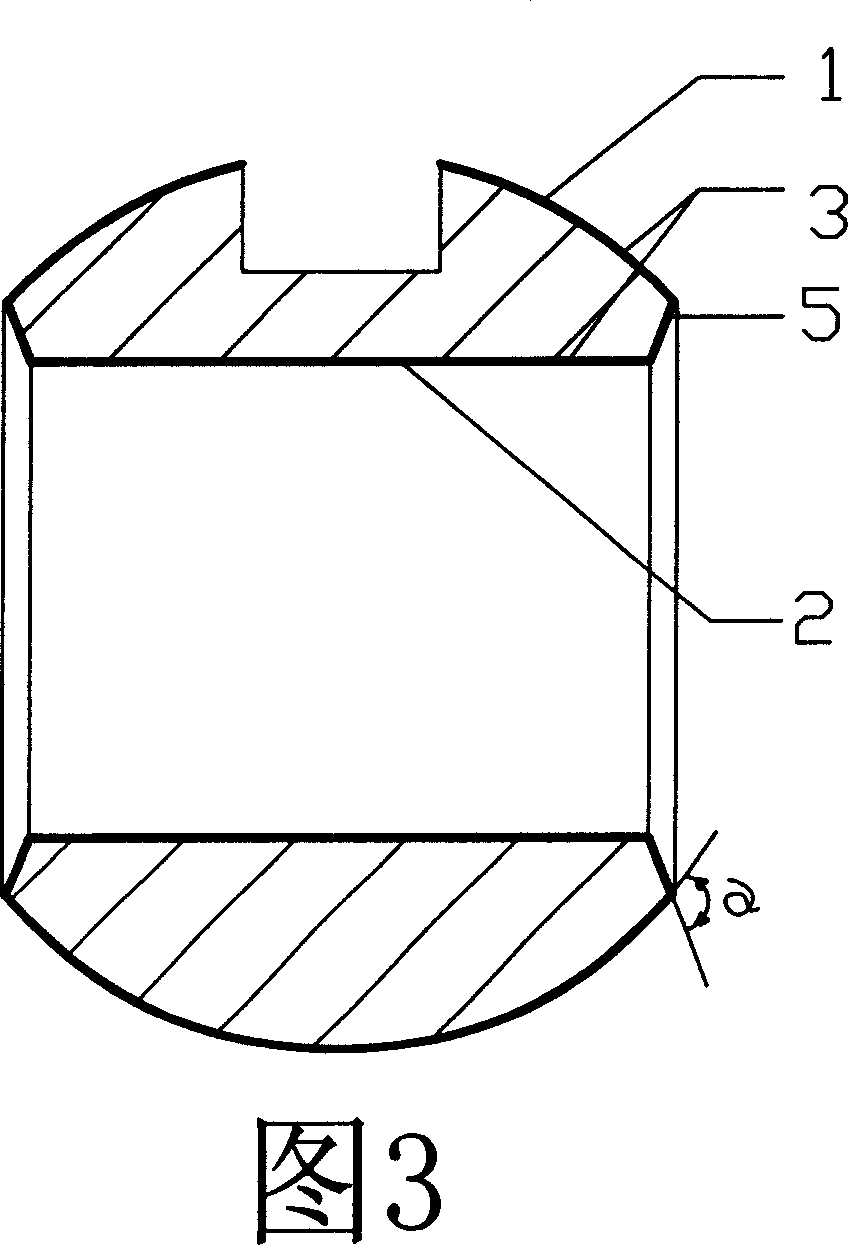

[0014] Among them: 1. The outer spherical surface; 2. The inner cylindrical surface of the through hole; 3. The chromium oxide coating; 4. The transitional arc surface; 5. The transitional conical surface; The angle between the faces at the junction of the two.

[0015] As shown in Figure 1, it is a valve core that does not adopt a transition surface structure. The outer spherical surface 1 of the sphere and the inner cylindrical surface 2 of the through hole are covered with a chromium oxide coating 3, but the outer spherical surface that is stressed is the same as the adjacent The angle α between the non-stressed surfaces is an acute angle, which makes the strength of the junction between the stressed surface and the adjacent non-stressed surface relatively poor, which will affect the stability of the combination of the chromium oxide coating and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com