Optical module heat radiation device and radiator and communication device

A technology for a heat dissipation device and a communication device, which is applied to lasers, laser parts, semiconductor lasers, etc., can solve the problems of not effectively improving the heat dissipation effect of the optical module, and the contact effect is not good, so as to improve the heat dissipation effect and enhance the contact effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

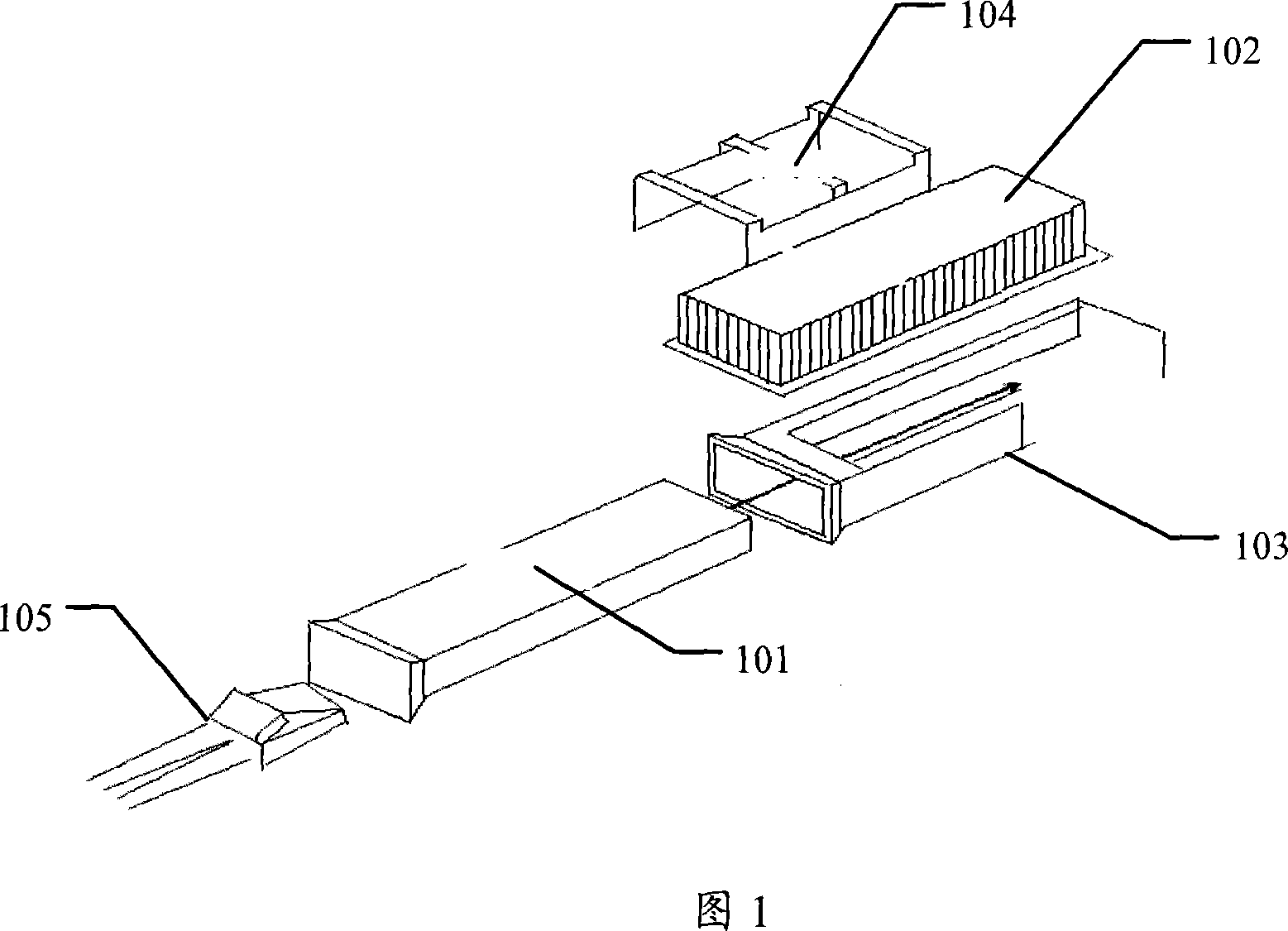

[0016] Embodiments of the present invention provide a cooling device for an optical module, a heat sink, and a communication device, which are used to effectively dissipate heat for the optical module.

[0017] The embodiments of the present invention mainly improve the heat dissipation efficiency of the heat sink by reducing the contact thermal resistance between the heat sink and the optical module.

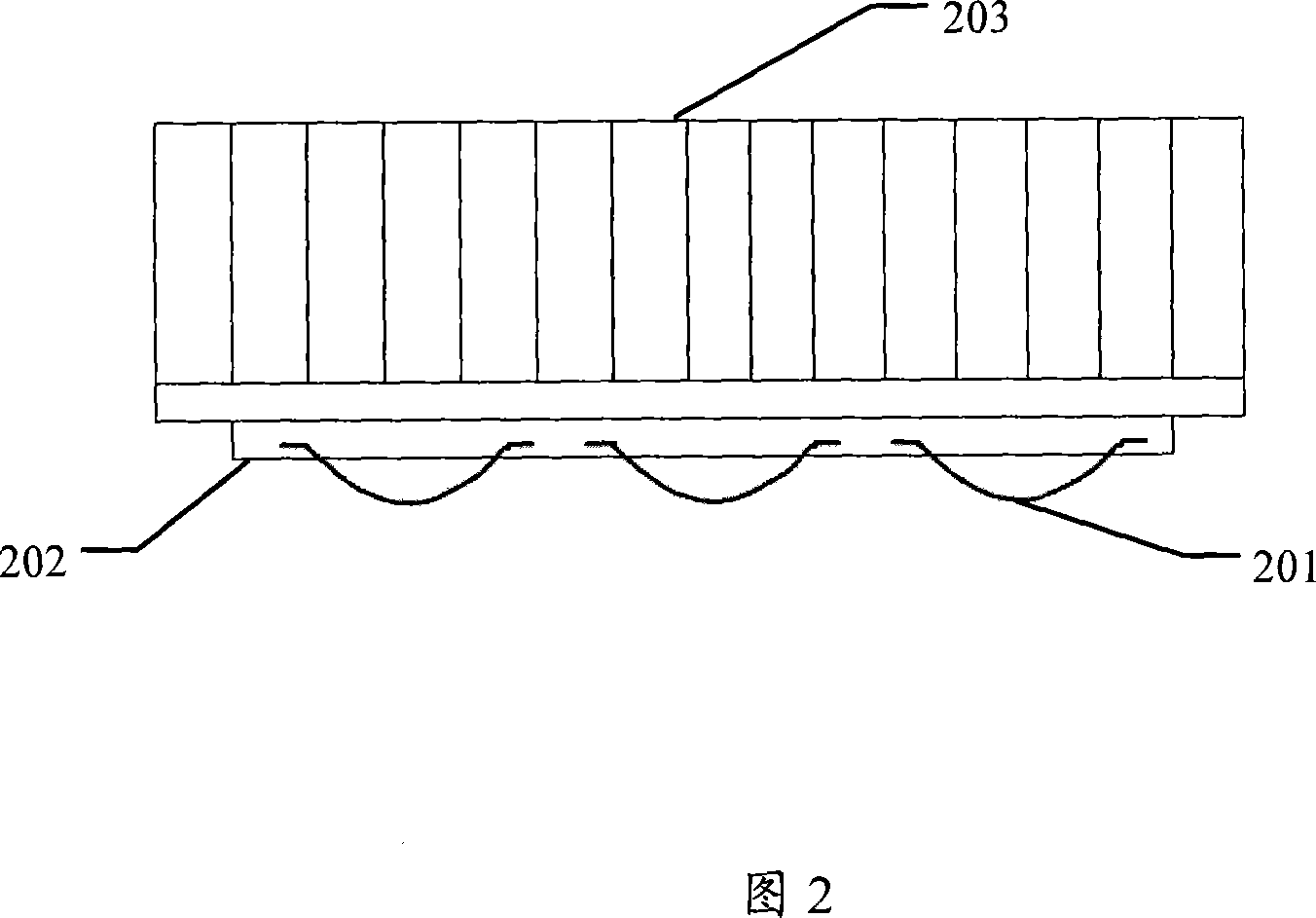

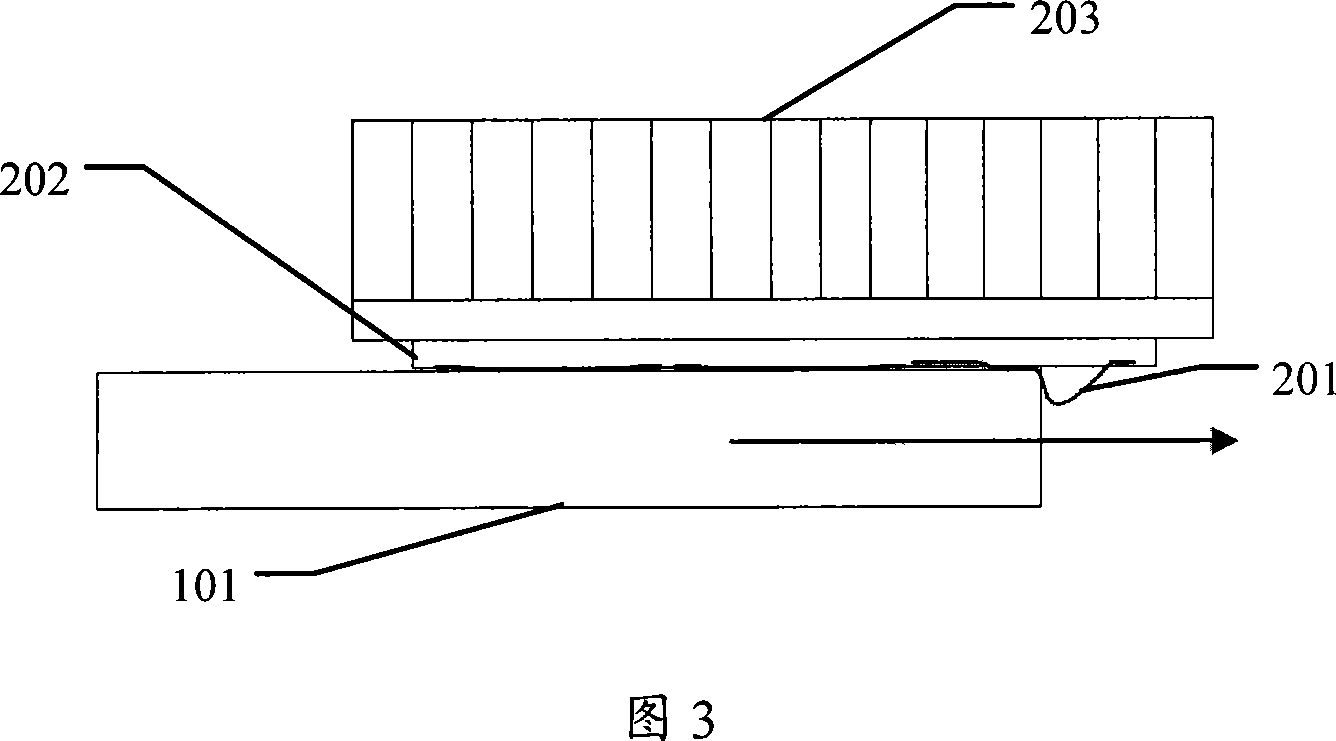

[0018] Referring to Fig. 2, the radiator embodiment in the embodiment of the present invention is:

[0019] The heat sink includes a heat dissipation layer 203 and a heat-absorbing surface 202 at the bottom. Several curved reeds 201 are inlaid on the heat-absorbing surface 202. Since the curved reeds 201 are compressible, they can achieve close contact with the optical module. , improve cooling efficiency.

[0020] The curved reed 201 before installation is in a natural state. During the installation of the optical module, the curved reed 201 will be deformed. The curved reed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap