Controller of the vibration of the top of the high-pressure dust-cleaning machine

A high-voltage dust removal and controller technology, applied in the direction of electrostatic separation, electrode cleaning, etc., can solve the problems of low control precision of rapping intensity and large step distance of pulse width adjustment, so as to achieve simple and convenient user operation, realize precise control, and simplify input The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings.

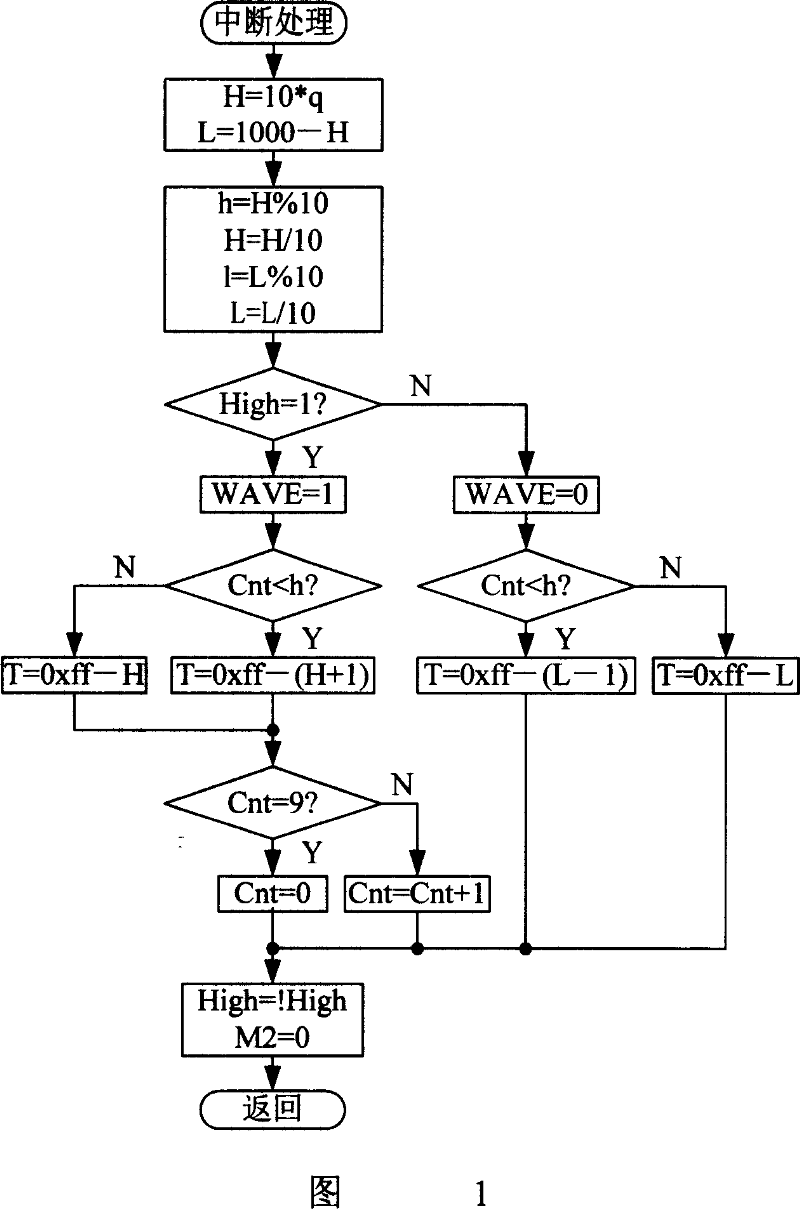

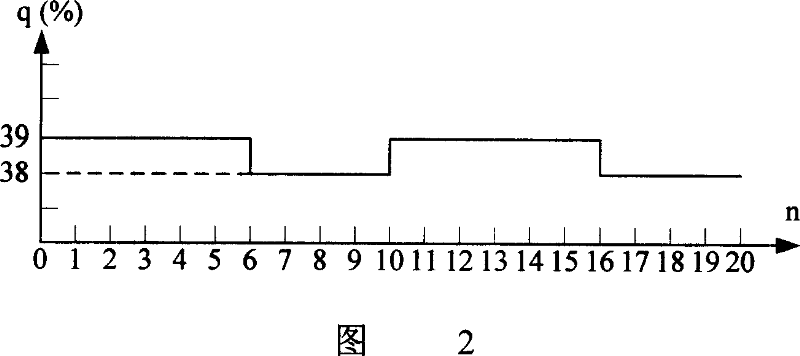

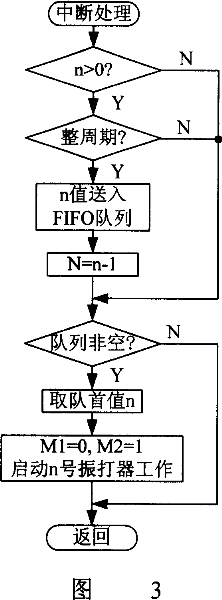

[0023] 1-7, a high-voltage dust removal top rapping controller, including a signal input terminal connected to the timer 1 that generates a PWM signal in the microprocessor, and a signal output terminal connected to the high-voltage dust removal top rapping main circuit 2 And a sequence control module 3 that controls the operation of the rapper according to the sequence of the rapping time, the sequence control module 3 is connected to the signal output terminal, and the controller further includes a non-uniform pulse width control module 4, the non-uniform pulse width The wide control module 4 includes: a parameter preset unit 5 for setting m PWM pulse signals as one cycle according to the control precision, dividing the duty cycle q of the PWM signal into an integer part and a decimal part, and setting the integer The part is the base of the timer preset number, the product of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com