System and method for packaging tobacco

A technology of tobacco and tobacco leaves, which is applied in the field of stacking tobacco sheets, which can solve the problems of low packaging efficiency, high height of the whole machine, and bulky volume, and achieve the effects of improving packaging efficiency, uniform density, and reducing overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

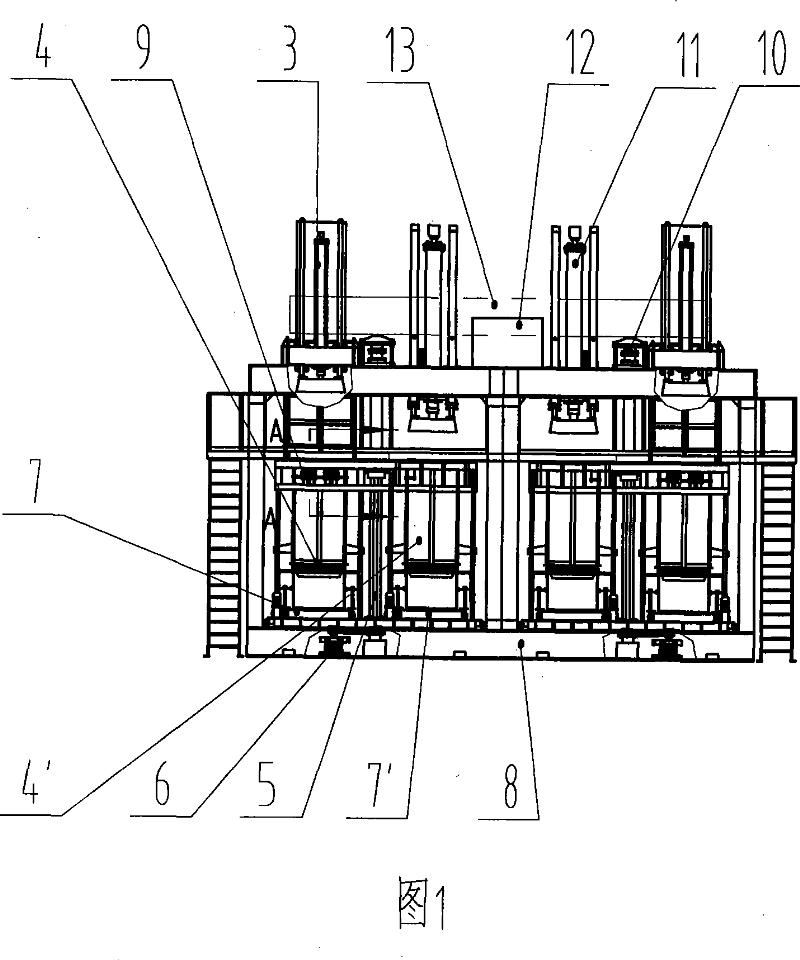

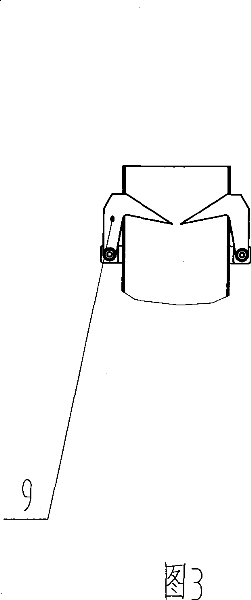

[0014] As shown in the figure, the system of the present invention includes a liftable pre-compression mechanism 3 and a compaction mechanism 11 installed on a frame 8, and a liftable material box 4 is respectively arranged below the pre-compression mechanism 3 and the compaction mechanism 11. , 4', below the material box is provided with a rotary box mechanism 6 for placing the material box and the smoke box and can rotate along the rotating shaft 5, and a jacking device 10 for jacking up the rotary box mechanism and the material box is also provided on the frame , the upper part of the feed box is provided with a hook material mechanism 9 that prevents the pre-pressed tobacco leaves from overflowing the feed box.

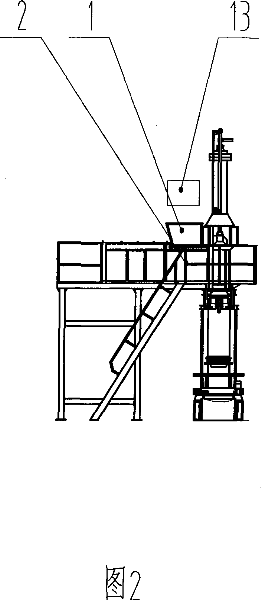

[0015] The system of the present invention is provided with two conveying mechanisms 7, 7' that send the packaged cigarette box into the pre-pressing and compacting station on the transfer box mechanism; A feeding mechanism 1 with metering is arranged above the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com