Dynamic micromixer

A technology of reactors and anaerobic reactors, applied in the direction of mixers, biochemical instruments, chemical instruments and methods, etc., can solve problems such as disadvantages and death, and achieve the effects of reducing heat loss, clear temperature and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

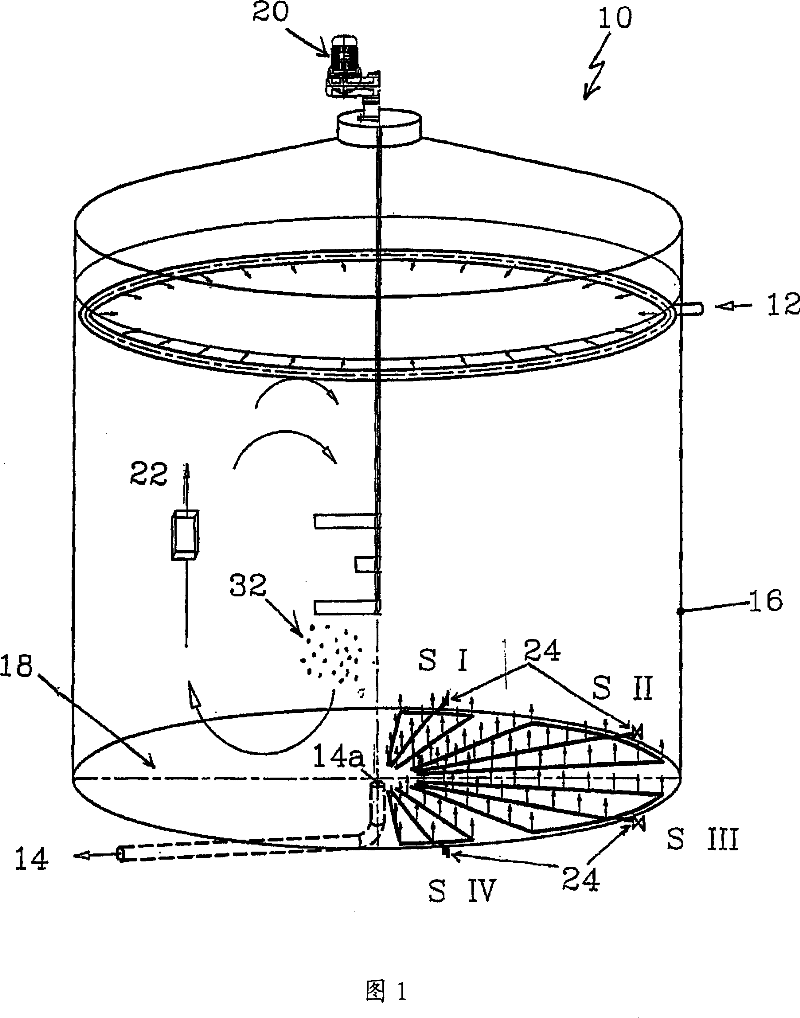

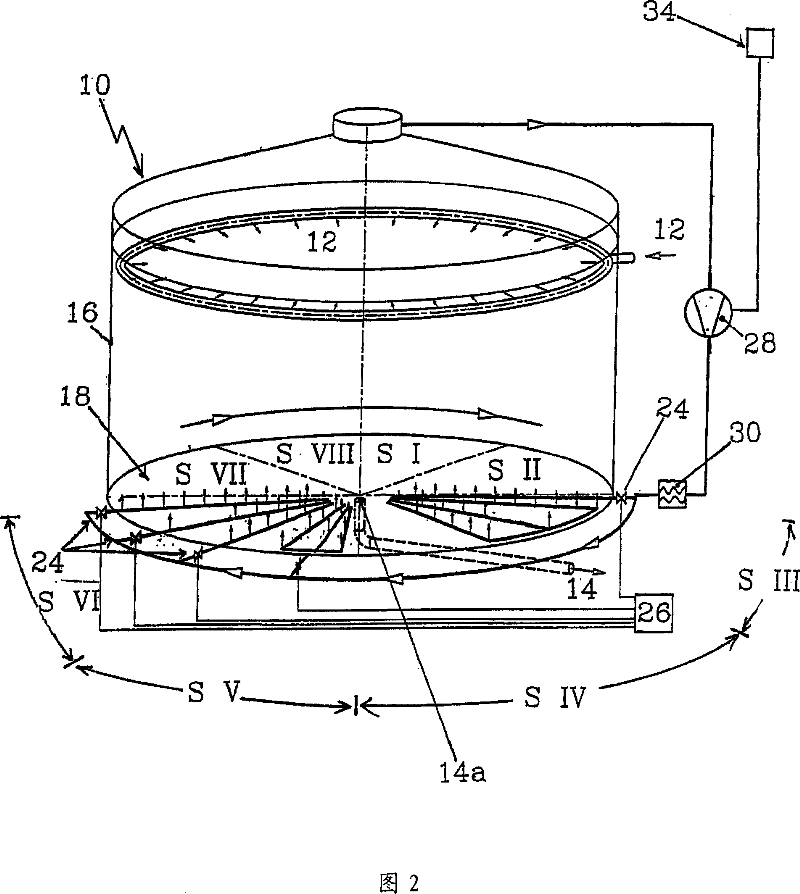

[0056] In Fig. 1, a circular biogas generator 10 is shown in perspective, wherein, the left side of Fig. 1 is a traditional overturning method carried out by means of a stirrer 20 known in the background art (only partially shown in the figure) . In the upper region of the reactor, the feed added at the feed opening 12 is turned over by the stirrer 20 according to the arrows shown in the figure on the left. After reaching the usual residence time in the reactor, the overturned biological material is discharged from the material outlet 14 at the bottom 18 of the reactor. In the background art as explained in the left half of the figure by slug flow 22, so-called flow paths (Stromfaeden) (longer vertical arrows) are formed by turning over an electric stirrer, in which, in view of the absence of internal mixing, in the reaction A complete volume of material is formed in the container. Naturally, at least part of the incoming material is also conveyed rapidly to the discharge op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com