Dumb-bell shaped stator linear type ultrasound motor

A technology of ultrasonic motor and shaped stator, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. It can solve the problems of large volume, low output efficiency, and complex structure. Achieve the effects of small size, large output thrust and simple motor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

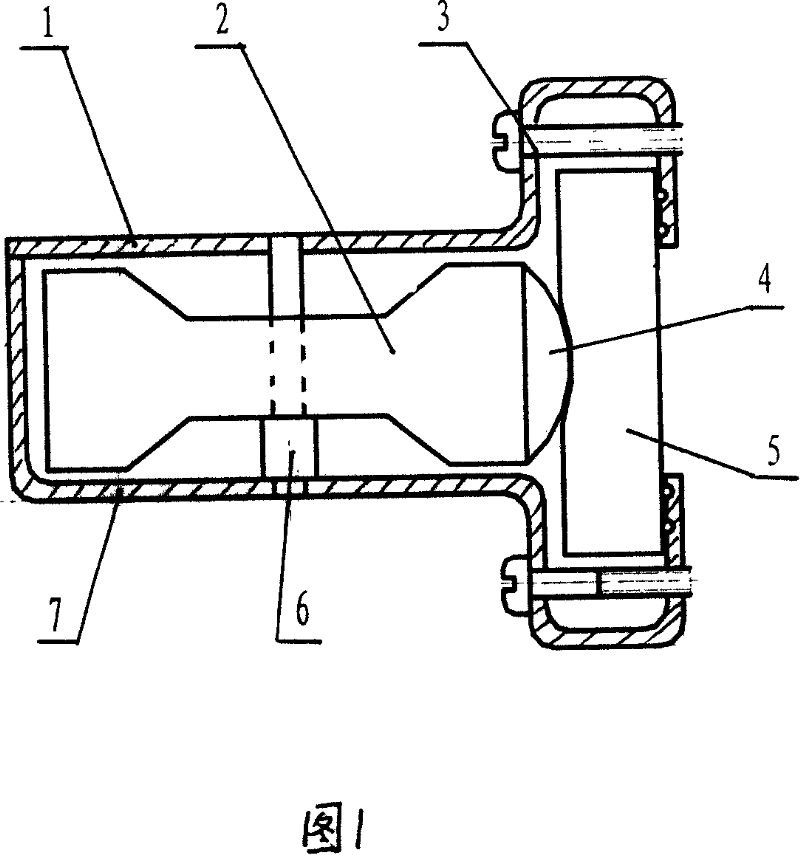

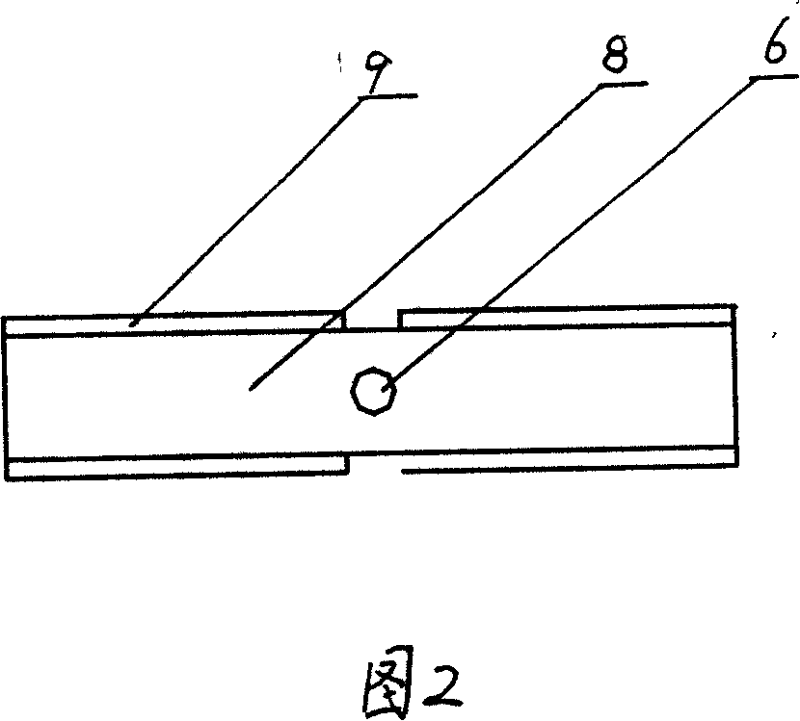

[0012] An embodiment is described in detail according to FIG. 1 and FIG. 2 .

[0013] As shown in the figure, the motor of the present invention includes the stator 2, the guide rail (mover) 5 and the casing 7 of the existing linear ultrasonic motor, and the dumbbell-shaped stator 2 is fixed with the fixed shaft 6 in the casing 7, and the Both sides of the substrate 8 are pasted with piezoelectric ceramic sheets 9, and one end of the stator 2 has a wear-resistant head 4, and the wear-resistant head 4 is placed on the guide rail 5, and then the case cover 1 is fixed with screws 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com