Different capacitance impeller-type internal combustion engine

An internal combustion engine, impeller type technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the inconvenient maintenance, the air intake can not meet the requirements of full combustion of fuel, and it is difficult to achieve the working volume ratio, etc. problem, to achieve the effect of improving engine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

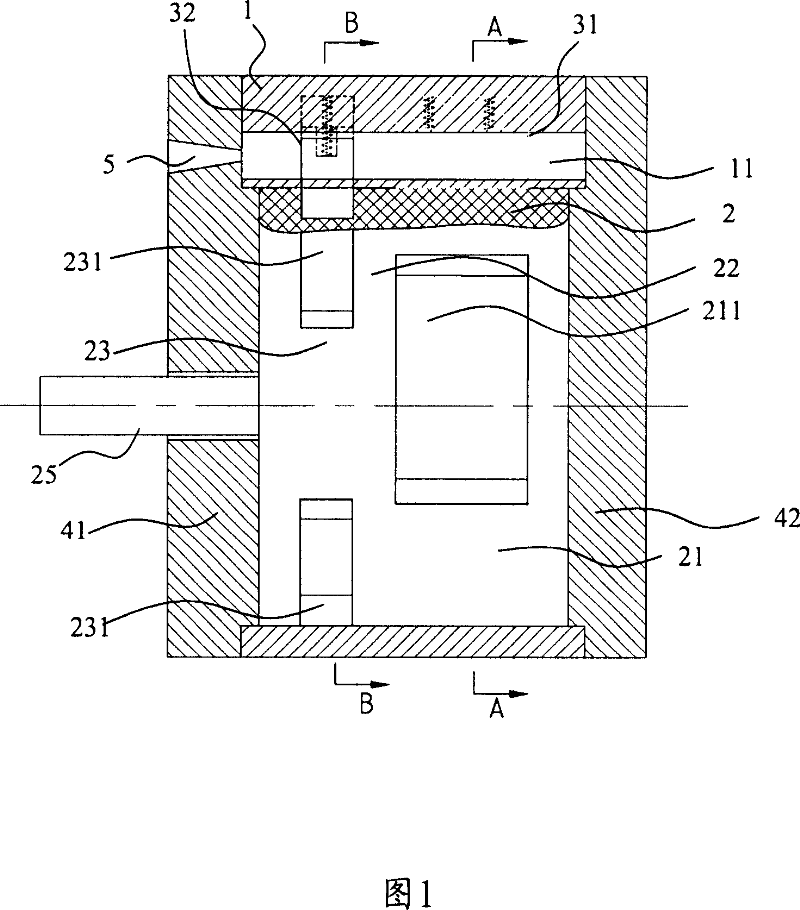

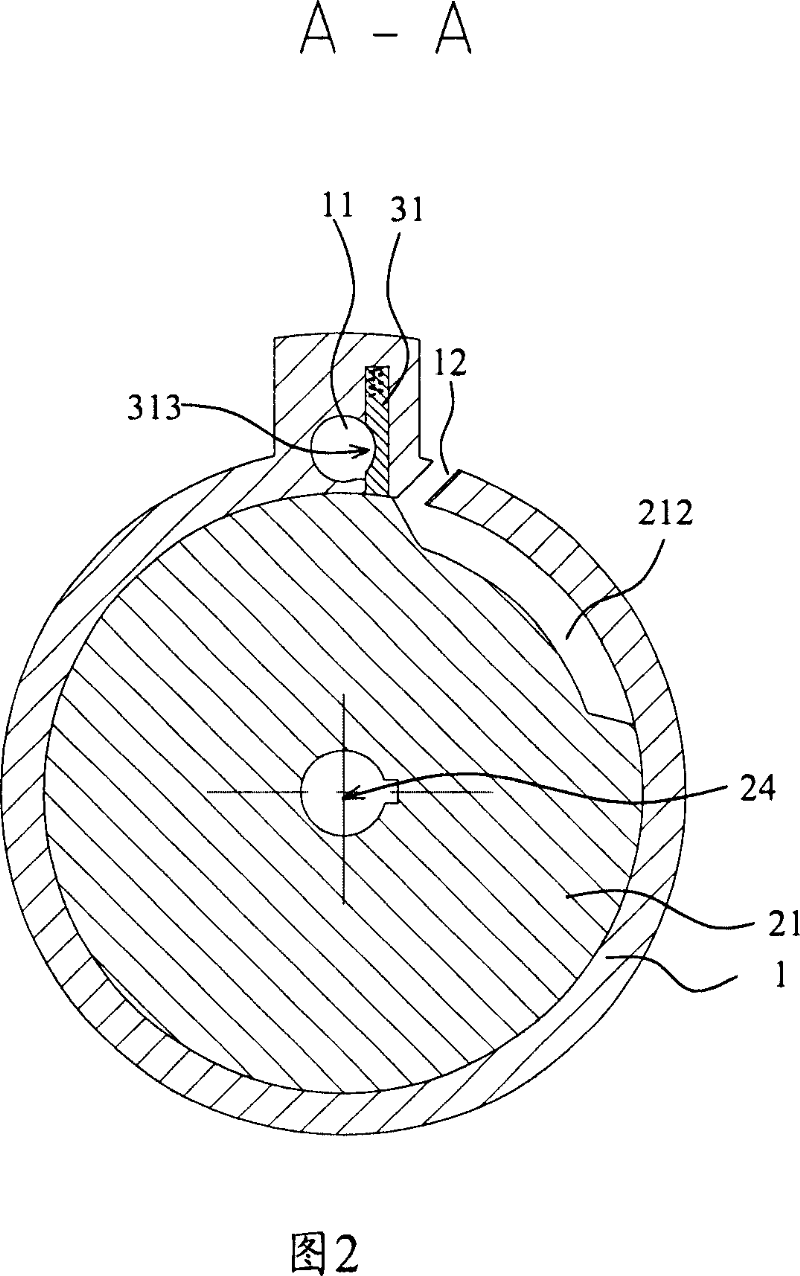

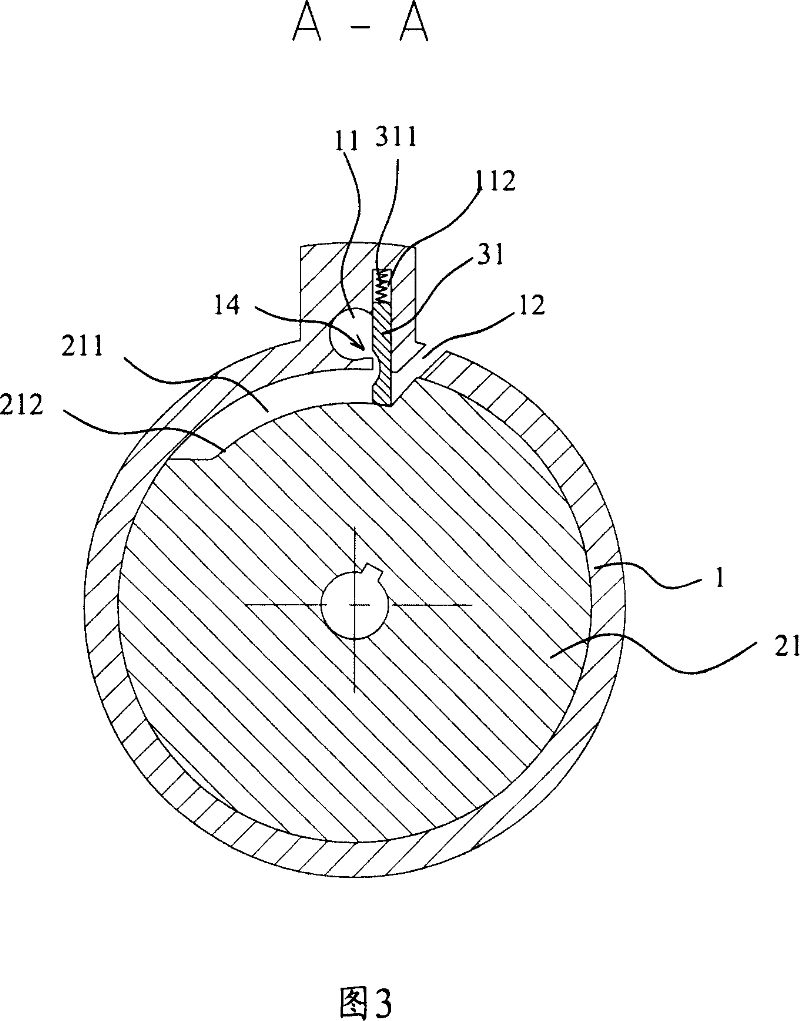

[0026] Referring to Fig. 1, the differential impeller internal combustion engine of the present invention includes a body 1 and a rotor 2 that can rotate relatively in the body 1, and end covers 41, 42 positioned at both ends of the rotor, and the engine outputs power through the rotation of the rotor 2.

[0027] The rotor 2 includes a compression section 21 and a working section 23 arranged axially. The compression section 21 realizes suction and compression, and provides compressed gas, such as air, atomized fuel oil, natural gas or a combination thereof, for the working section 23. The working section 23 realizes work and exhaust, and drives the rotor 2 to rotate.

[0028] The compression section 21 of the rotor 2 is characterized by an annular groove area 211, and the annular groove area 211 extends on a part of the circumferential surface of the rotor 2. For example, the circumferential surface occupied by the annular groove area 211 corresponds to a central angle of 60 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com