Hot pipe temperature measuring method

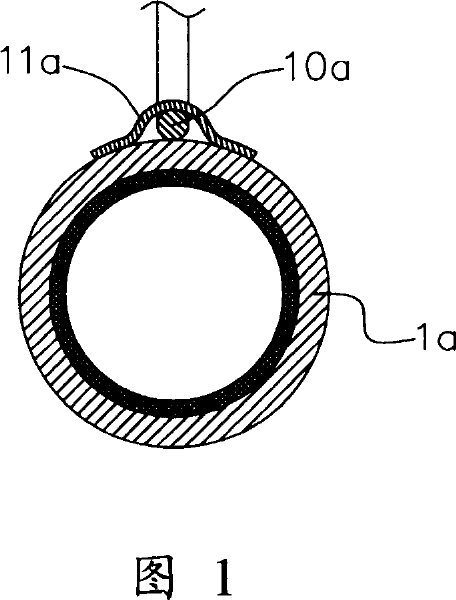

A technology of heat pipes and temperature sensing heads, which is applied in thermometers, measuring devices, and measuring heat, and can solve problems such as deformation of heat pipes 1a, affecting product quality, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

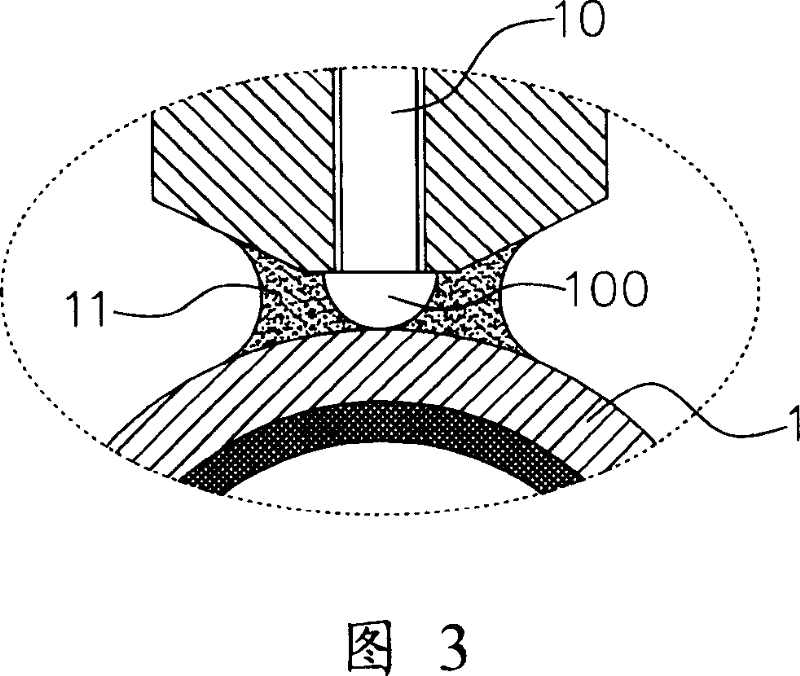

[0022] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and drawings of the present invention. However, the attached drawings are only for reference and description, and are not used to limit the present invention.

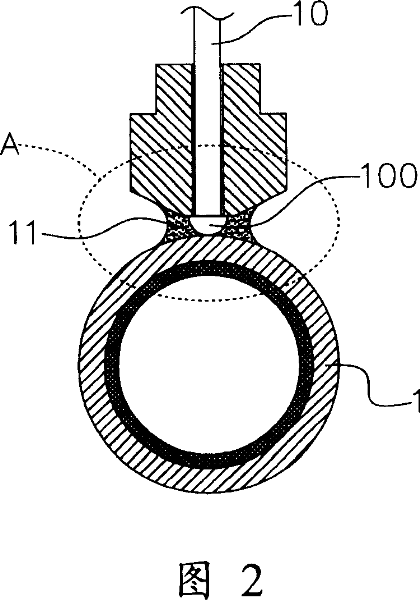

[0023] 2 and 3 are a schematic diagram of the implementation of the present invention and an enlarged view of part A of FIG. 2 respectively. The present invention provides a method for measuring the temperature of a heat pipe. The thermocouple wire 10 is firstly prepared. A temperature sensing head 100 is formed at one end of the thermocouple wire 10, and the other end is used to connect a temperature sensing device (the figure is omitted). Or record the measured temperature, and transmit the measured temperature signal to the temperature sensing device through the temperature sensing head 100 of the thermocouple wire 10.

[0024] The forming method of the temperature sensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com