Liquid crystal display and mfg. method therefor

A technology of a liquid crystal display device and a manufacturing method, which are applied to static indicators, photoengraving processes of pattern surfaces, optics, etc., can solve the problems of poor transmittance, slow response time, and inability to meet requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The details of the present invention and its practical preferred examples will be described with reference to the accompanying drawings.

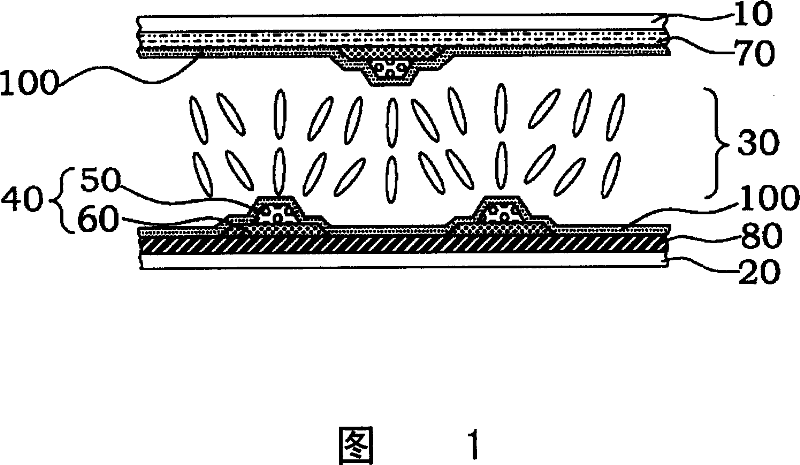

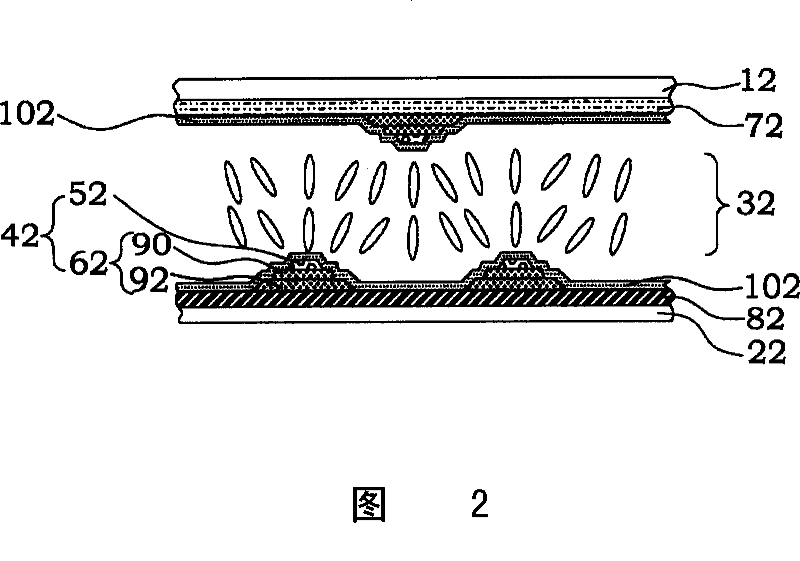

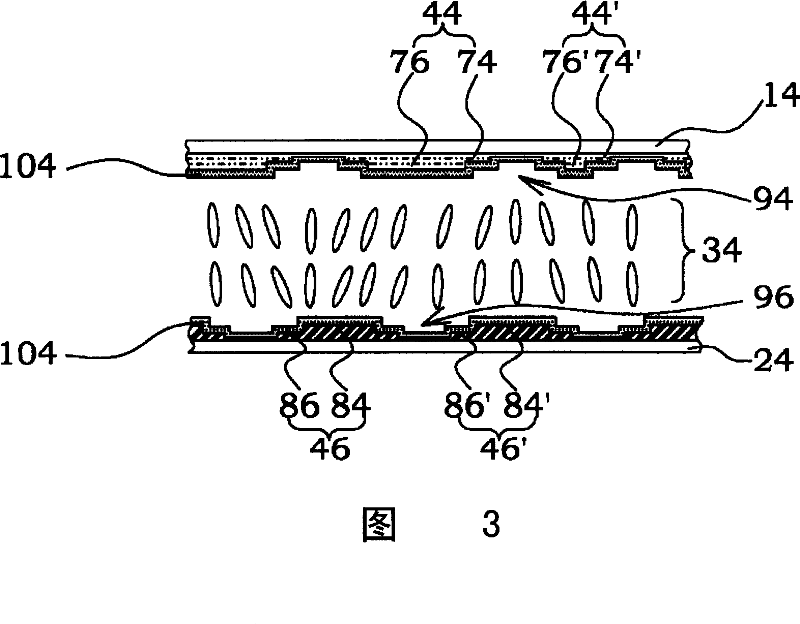

[0015] Please refer to FIG. 1 . First, FIG. 1 is a partial cross-sectional view of a liquid crystal display device according to a first embodiment of the present invention. The liquid crystal display device of this embodiment includes a first substrate 10 and a second substrate 20 opposite to the first substrate 10, wherein the first substrate 10 and the second substrate 20 can be made of glass material. In one embodiment, The first substrate also includes a transparent electrode 70 ; the second substrate also includes a pixel electrode 80 . A liquid crystal layer 30 is disposed between the first substrate 10 and the second substrate 20 . At least one alignment structure 40, such as a geometric block, is disposed on at least one of the first substrate 10 and the second substrate 20. In one embodiment, the alignment structure 40 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com