Carrier body for components or circuits

A technology of carrier and circuit, applied in the field of carrier, can solve the problem of limited utilization of thermal conductivity and achieve the effect of improving the performance of resisting thermal alternation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

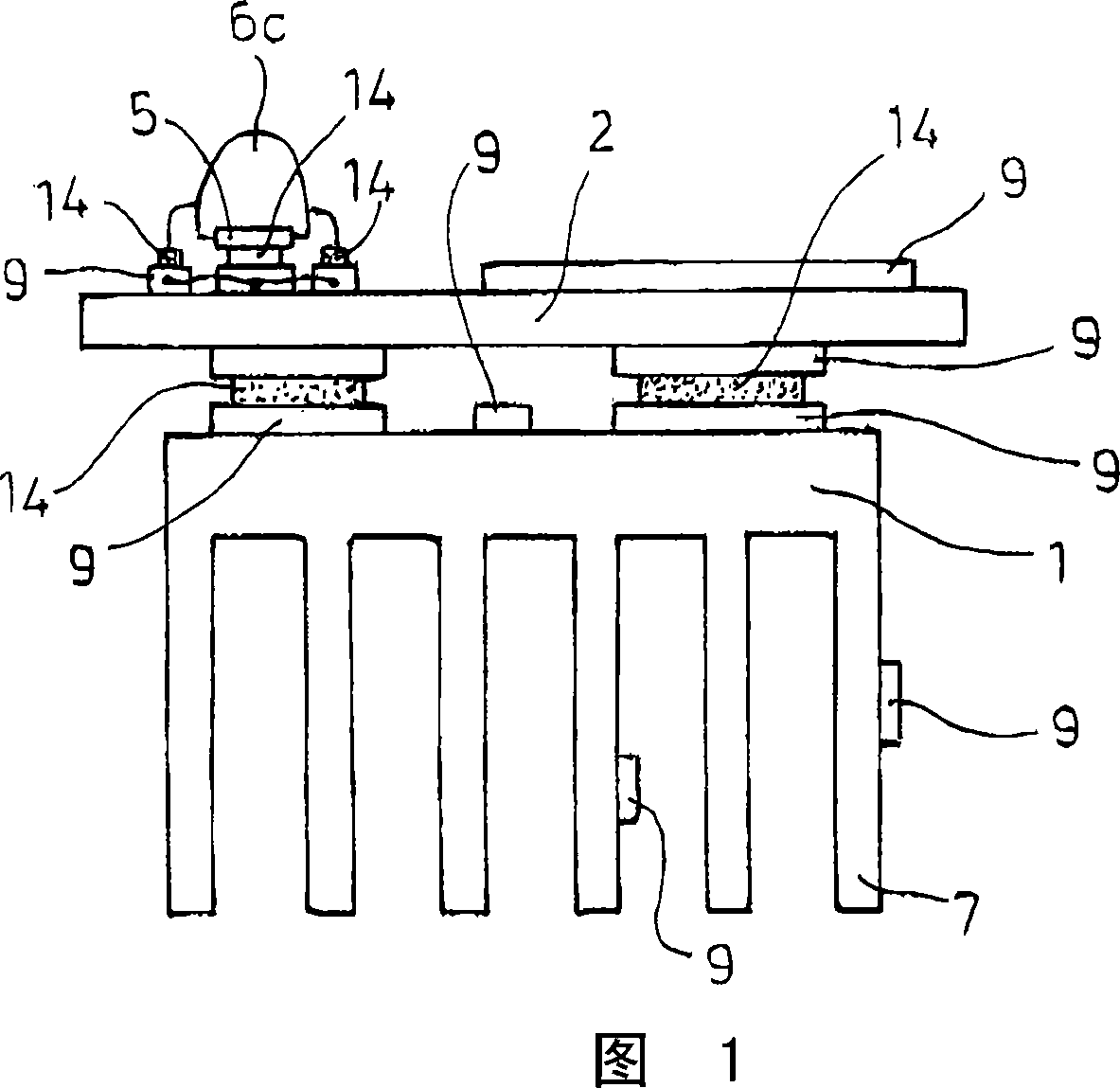

[0127] FIG. 1 shows an example of a carrier body 1 made of ceramics with a cooling element 7 made of ceramics, which is formed in one piece as a rib. On the carrier body 1 there is another independent carrier body 2 . Carrier 1 and carrier 2 each have a metal-containing, ie electrically conductive, layer 9 . The connection of the carrier body 2 to the carrier body 1 can be realized by means of a welded connection 14 . Heat dissipation or cooling of the carrier body 2 can thus take place via the carrier body 1 at the cooling element 7 . An LED 6 c can be mounted on the carrier 2 by connecting the base plate 5 of the LED 6 c to the metal-containing layer 9 of the carrier 2 via a solder connection 14 . The cooling component 7 is integrally connected with the carrier body 1 by sintering. The cooling element 7 itself can also serve as a carrier. Combinations of more than two carriers are also advantageous.

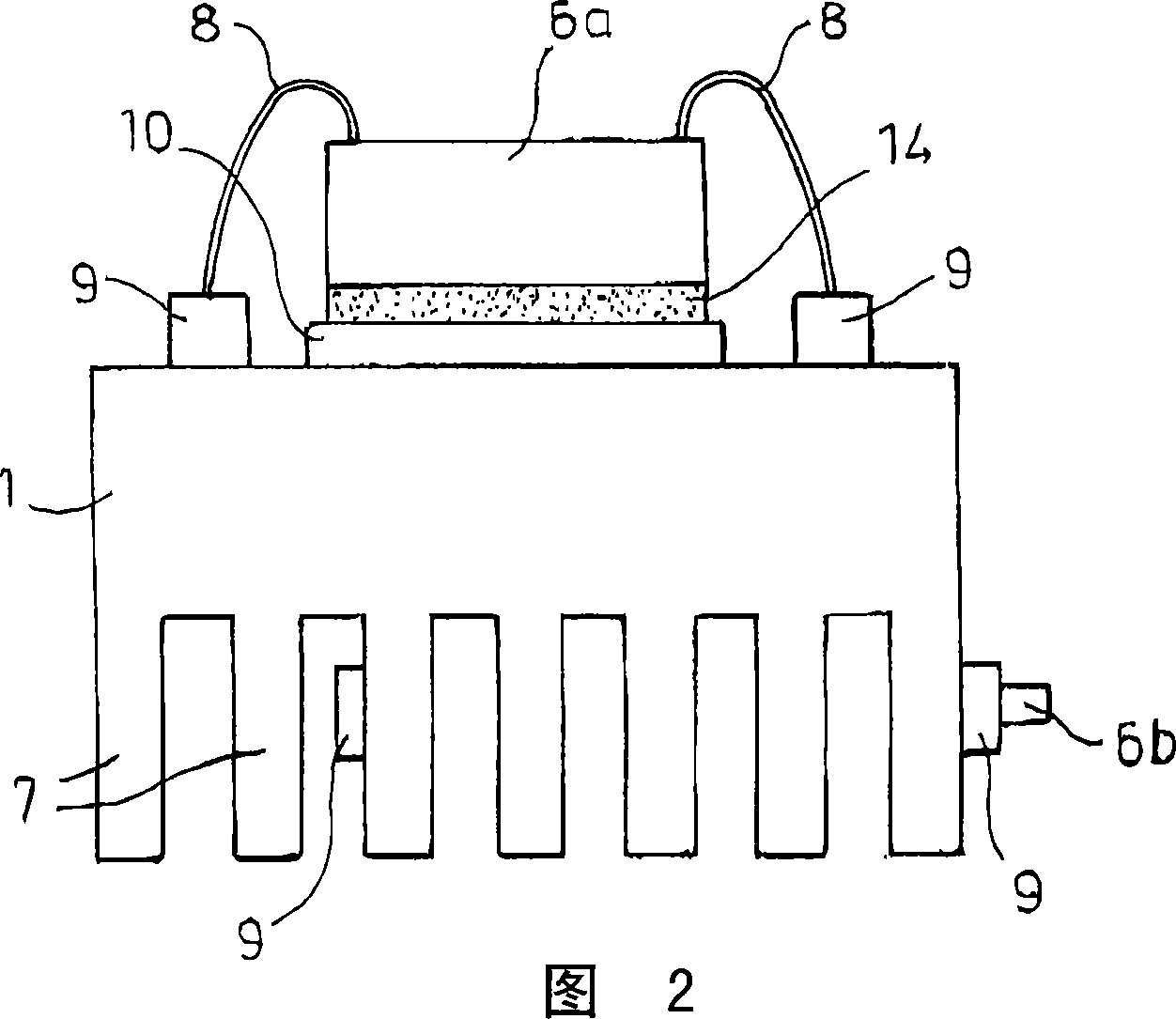

[0128] FIG. 2 shows a carrier body 1 made of ceramics with a cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com